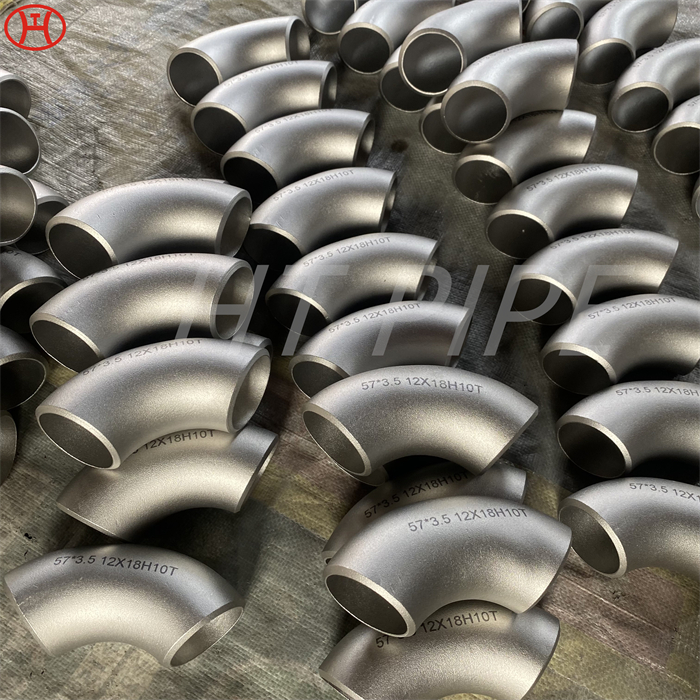

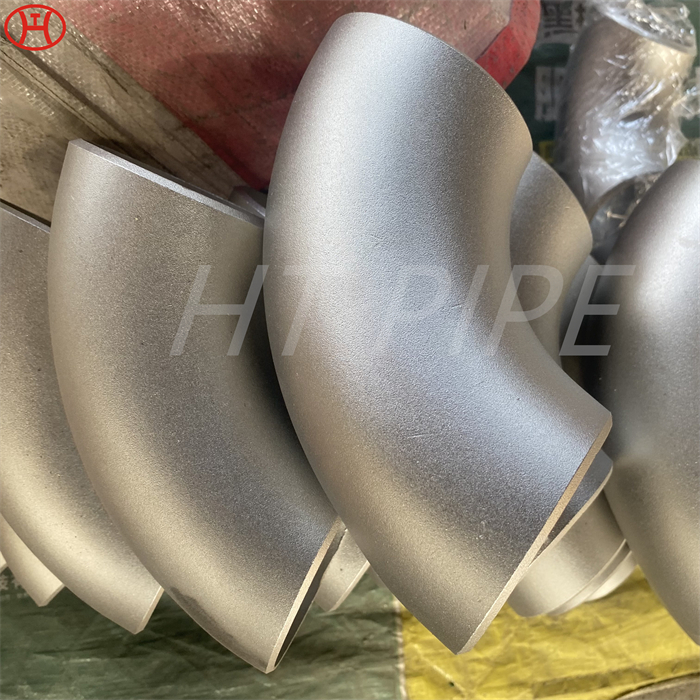

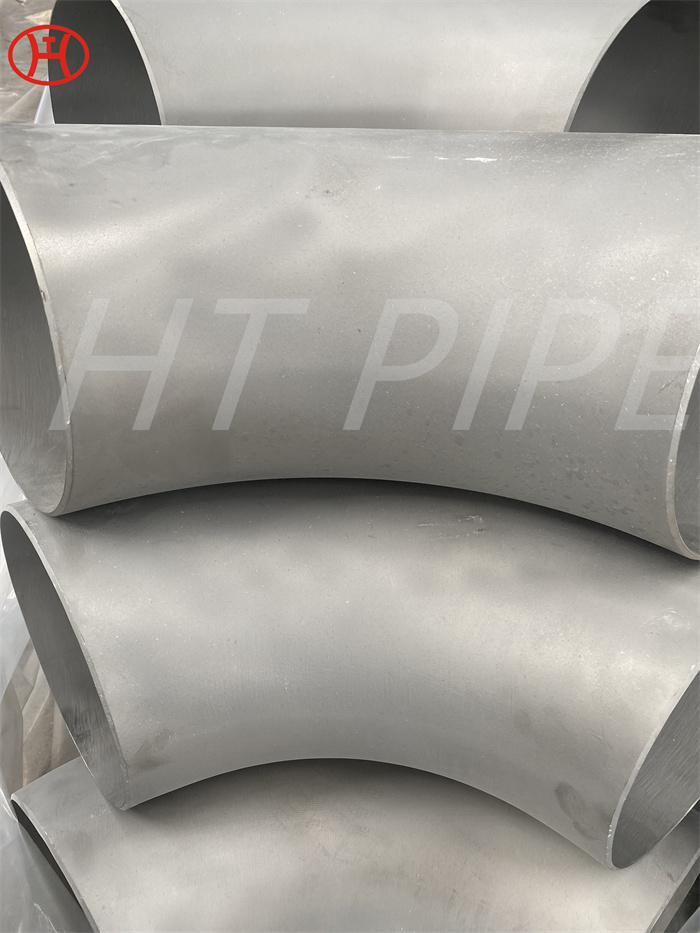

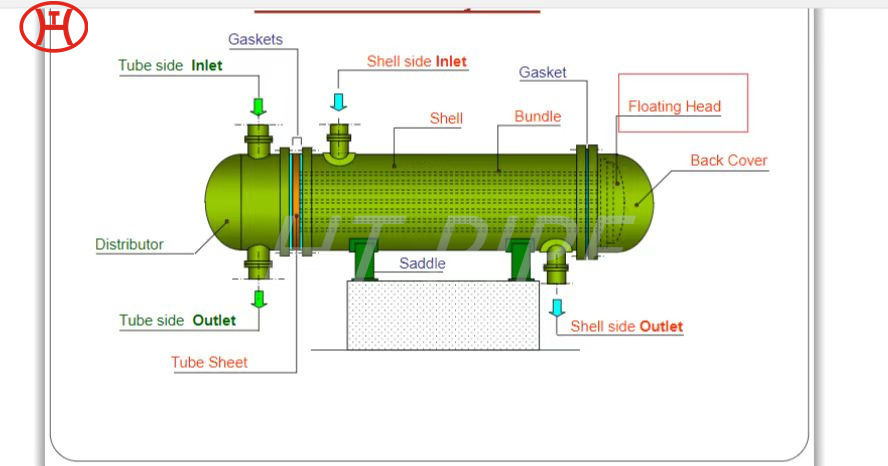

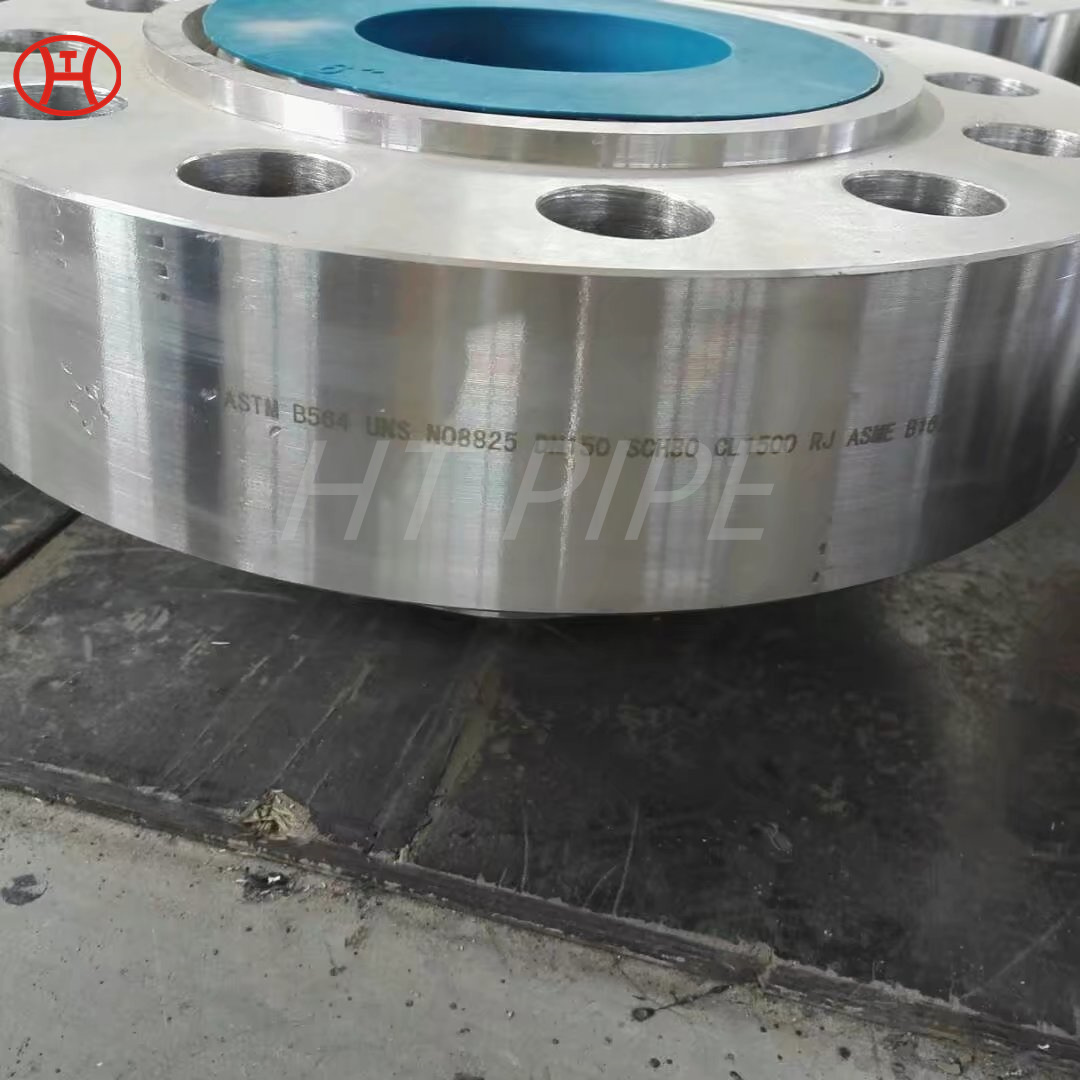

Incoloy 800HT Elbows for Hydrocarbon cracking and Industrial furnace and boiler components and equipment

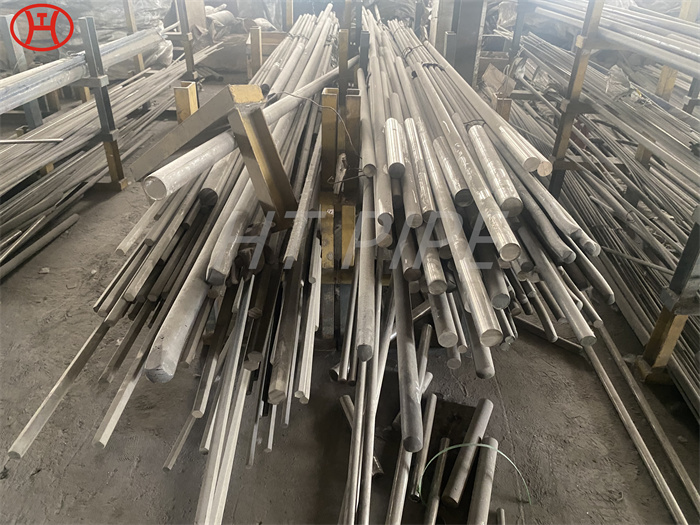

The higher strength results from deliberate control of the carbon, aluminum, and titanium contents in conjunction with a high-temperature anneal.

Alloy 800H/800HT has excellent resistance to nitric acid at concentrations up to 70% largely due to the chromium content. The alloy has good resistance to organic media like formic, acetic and propionic acids. Incoloy 800HT has further modifications to the combined titanium and aluminum levels (.85-1.20%) to ensure optimum high temperature properties.The nickel alloy is dual certified (800H/HT) and combines the properties of both forms. Incoloy 800H/HT alloy was intended for high temperature structural applications. Hot-working temperatures should be between 1600¡ãF and 2200¡ãF with heavy forming to be performed at temperatures above 1850¡ãF. No forming should be performed between 1200¡ãF and 1600¡ãF and preheating of tools and dies to 500¡ãF is suggested to avoid chill.