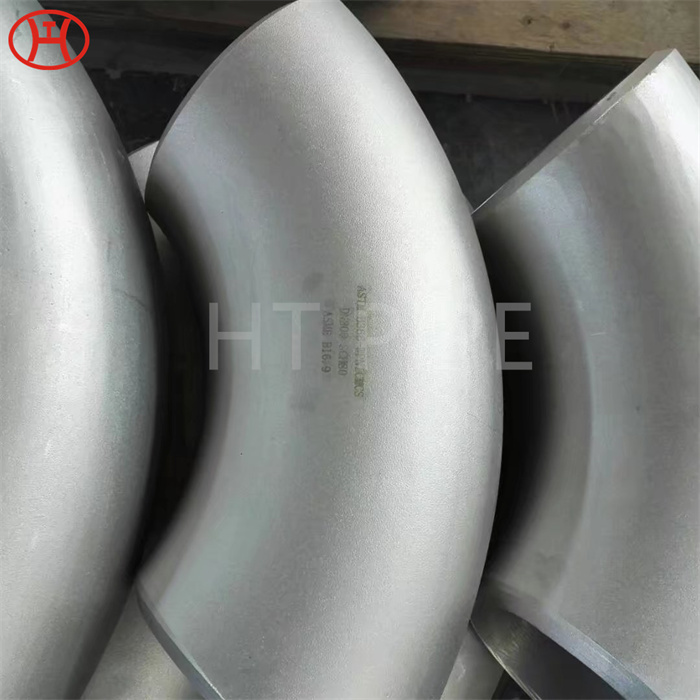

Incoloy 800HT Elbows Offers Excellent resistance to sulfidation and carburization

The combined effects of mechanical and thermal processing of Incoloy Alloy 800HT permit higher design stresses to be incorporated than are permitted for the conventional Alloy 800H.

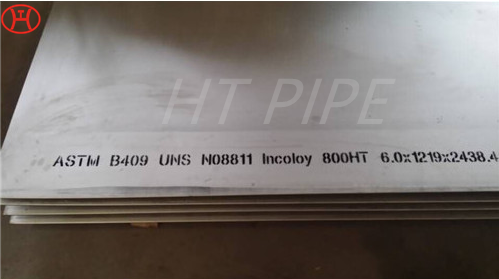

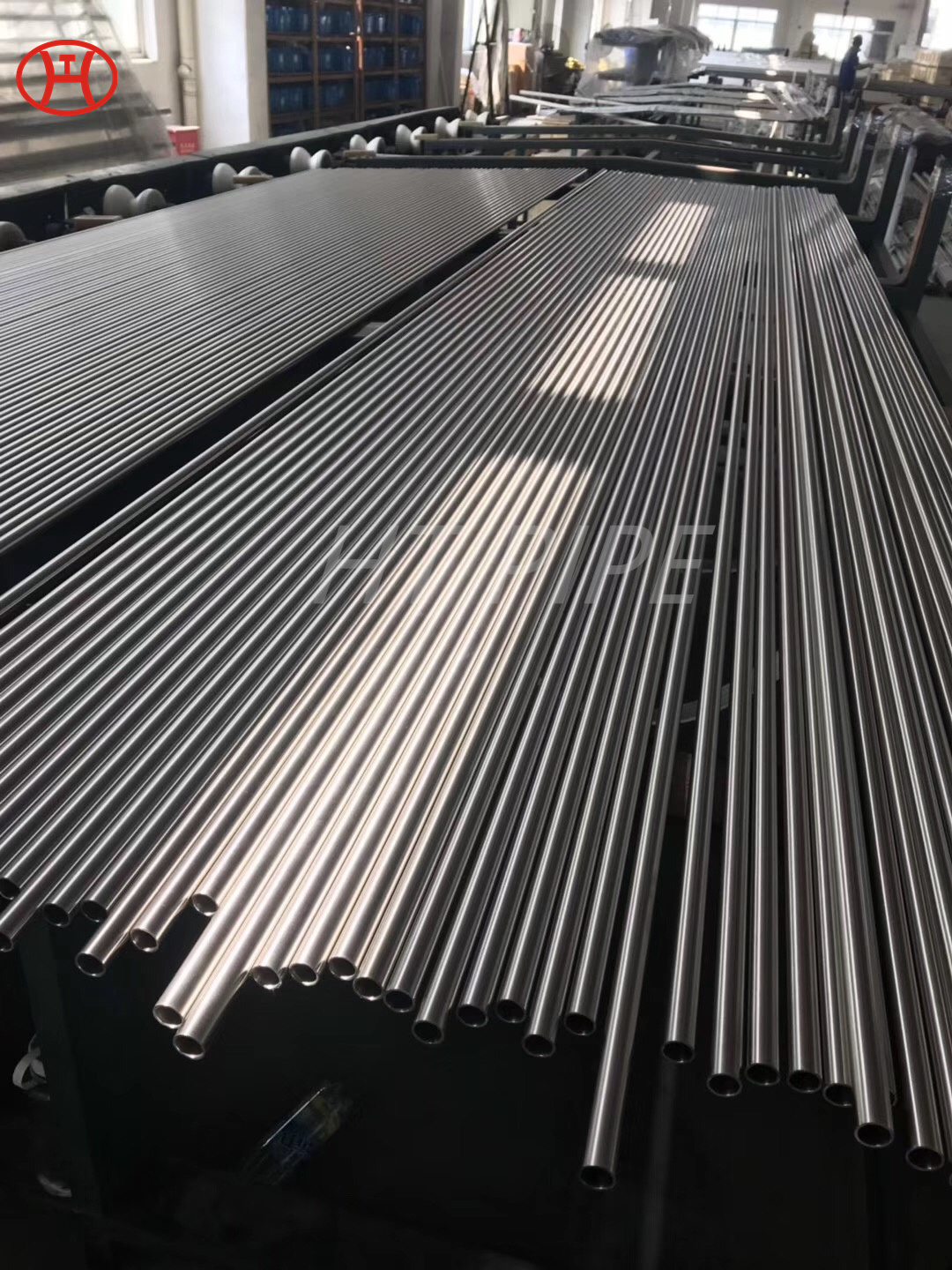

Excellent cold forming characteristics typically associated with the nickel-chromium alloys are exhibited with 800HT. Both alloy 800H and 800HT are generally considered to be superior to the base alloy 800 (UNS N08800) because of greater creep and stress rupture properties and a more restrictive C wt% range. Alloy 800H limits the C wt% from just 0.1% max in base alloy 800 to a 0.5% to 0.1% range. Incoloy group materials were first produced incoloy 800 and later new versions of incoloy 800h and incoloy 800ht were developed. Temperature and corrosion resistance are almost the same for these materials. Used in chemical and petrochemical processing, in power plants for super-heater and reheater tubing, in industrial furnaces, and for heattreating equipment.