Incoloy 800HT Seamless Tube Alloy 800HT Seamless Pipe Stockist and Supplier

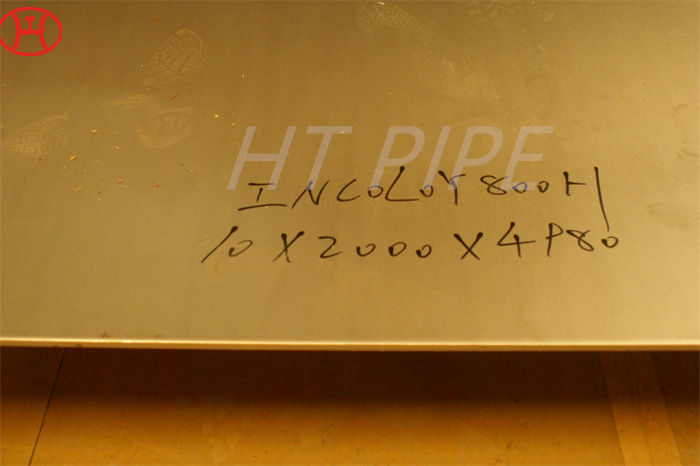

Alloys 800H and 800HT are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel, and 22% chromium.

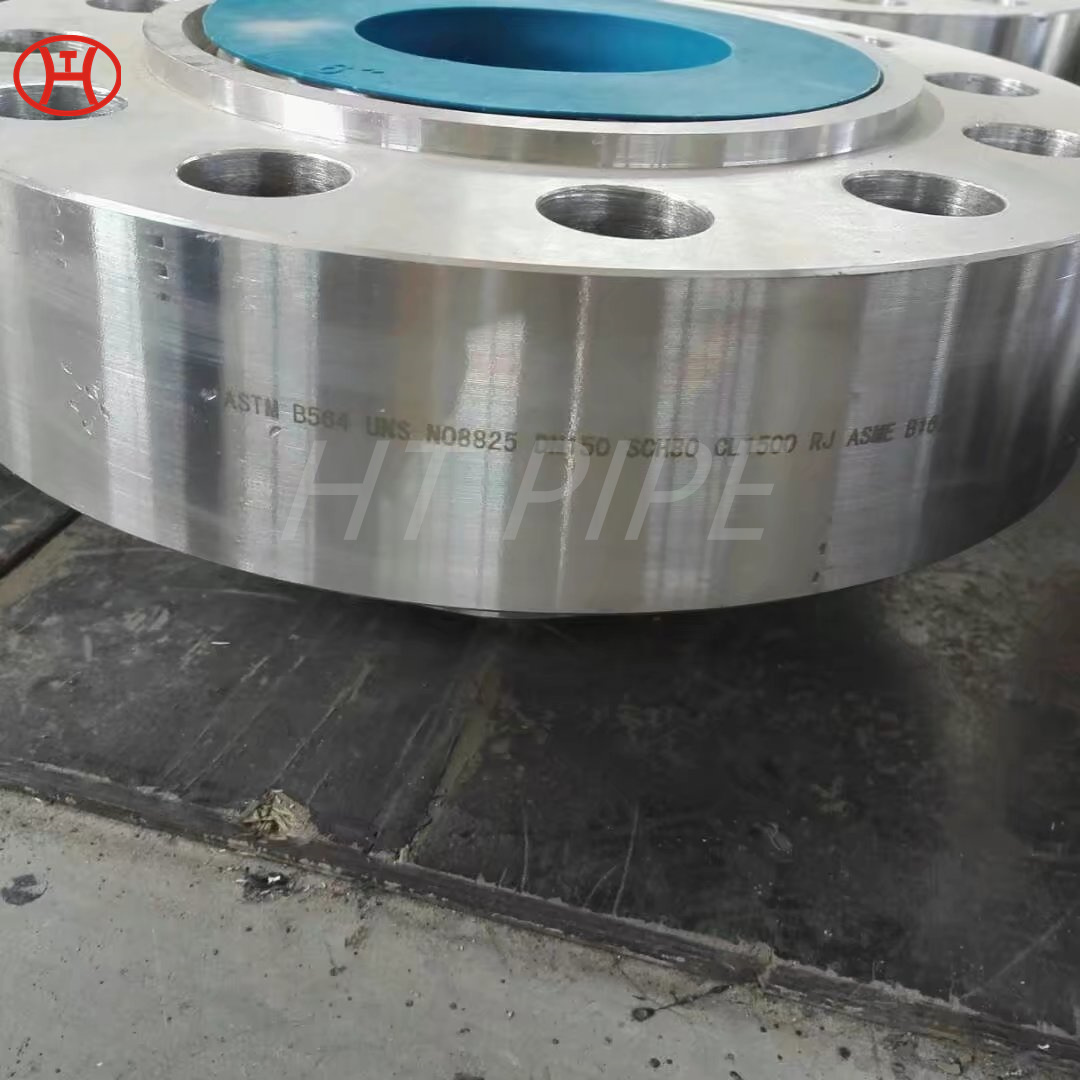

UNS N08811 / W.NR. 1.4959 Tube, ASTM B407 UNS N08811 Incoloy 800HT Tubing, Incoloy 800HT Pipe

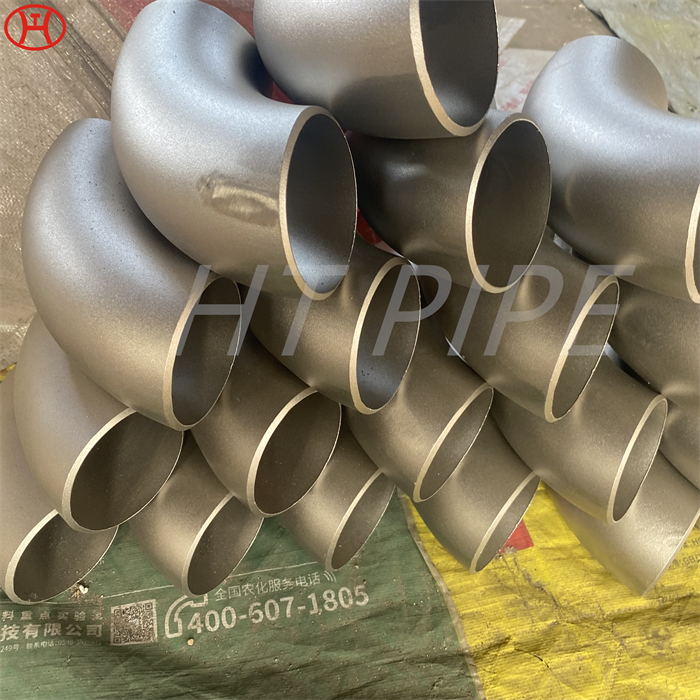

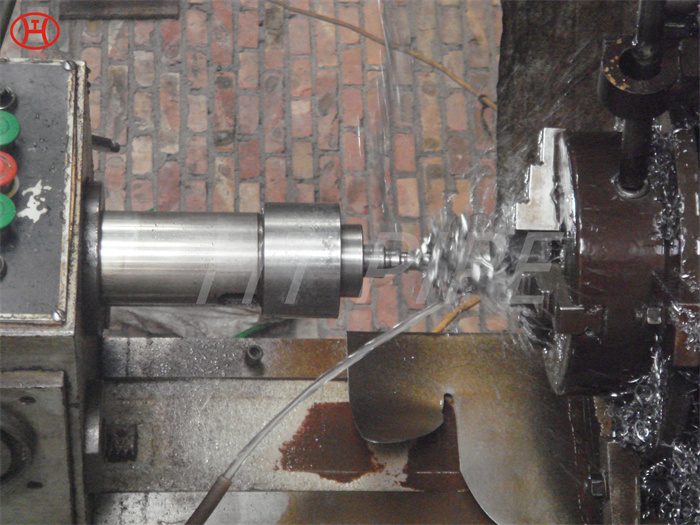

UNS N08811 pipe is to be subjected to either a hydrostatic test or a non-destructive eddy current test. Tests on the ASTM Sb 407 UNS N08811 Inconel 800ht Tubing is performed in order to not only determine the allowable fibre stress but also to detect any significant discontinuities. Generally, discontinuities such as a drilled hole or a transverse tangential notch could occur on the Incoloy Alloy 800ht Seamless Tube. The cold-drawn Din 1.4959 Tube, according to the ASTM B407 specification needs to be commercially straight.

Incoloy 800ht Welded Tube needs to be smooth, free of bends, kinks, as well as other injurious imperfections. This versatile alloy is reasonably priced at our company. To learn more about the price of ASTM B407 UNS N08811 Tubes in China. Nickel- chromium- iron based UNS N08811 pipe is an alloy that has exceptional corrosion resistance property at elevated temperatures ranging from 1200-1600° F. The chemical composition of Alloy 800ht Tube has been designed with the intent that 1.4959 tube has the ability to resist not only carburization, but also oxidation and nitriding atmospheres.

ASTM B407 Incoloy 800HT Tubing Mechanical Properties

| Alloy | Density | Melting Range | Tensile Stress | Yield Stress (0.2%Offset) | Elongation |

| Inconel 800HT Tubing | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Incoloy NCF 800HT Tube Chemical Composition

| Alloy | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60ᴬ | 0.15 – 0.60 |