INCOLOY 926 pipe fitting bw elbows

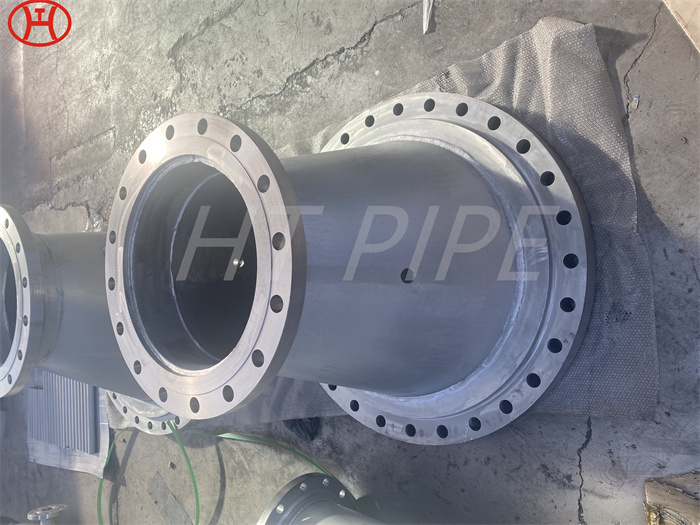

INCOLOY alloy 926 (UNS N08926 / W. Nr. 1.4529 / INCOLOY alloy 25-6MO) pipe fitting is a super-austenitic stainless steel containing 6% molybdenum and enhanced by an addition of nitrogen. The nickel and chromium contents of this alloy make it resistant to a wide range of corrosive environments.

INCOLOY 926 pipe fitting is made of an austenitic stainless steel alloy with a nitrogen content of 0.2% and a molybdenum content of 6.5% similar to 904 L. The molybdenum and nitrogen content greatly increase the resistance to crevice corrosion. At the same time, nickel and nitrogen can not only improve the stability, but also reduce the tendency to separate the crystal heat process or welding process better than the nitrogen content of the nickel alloy.

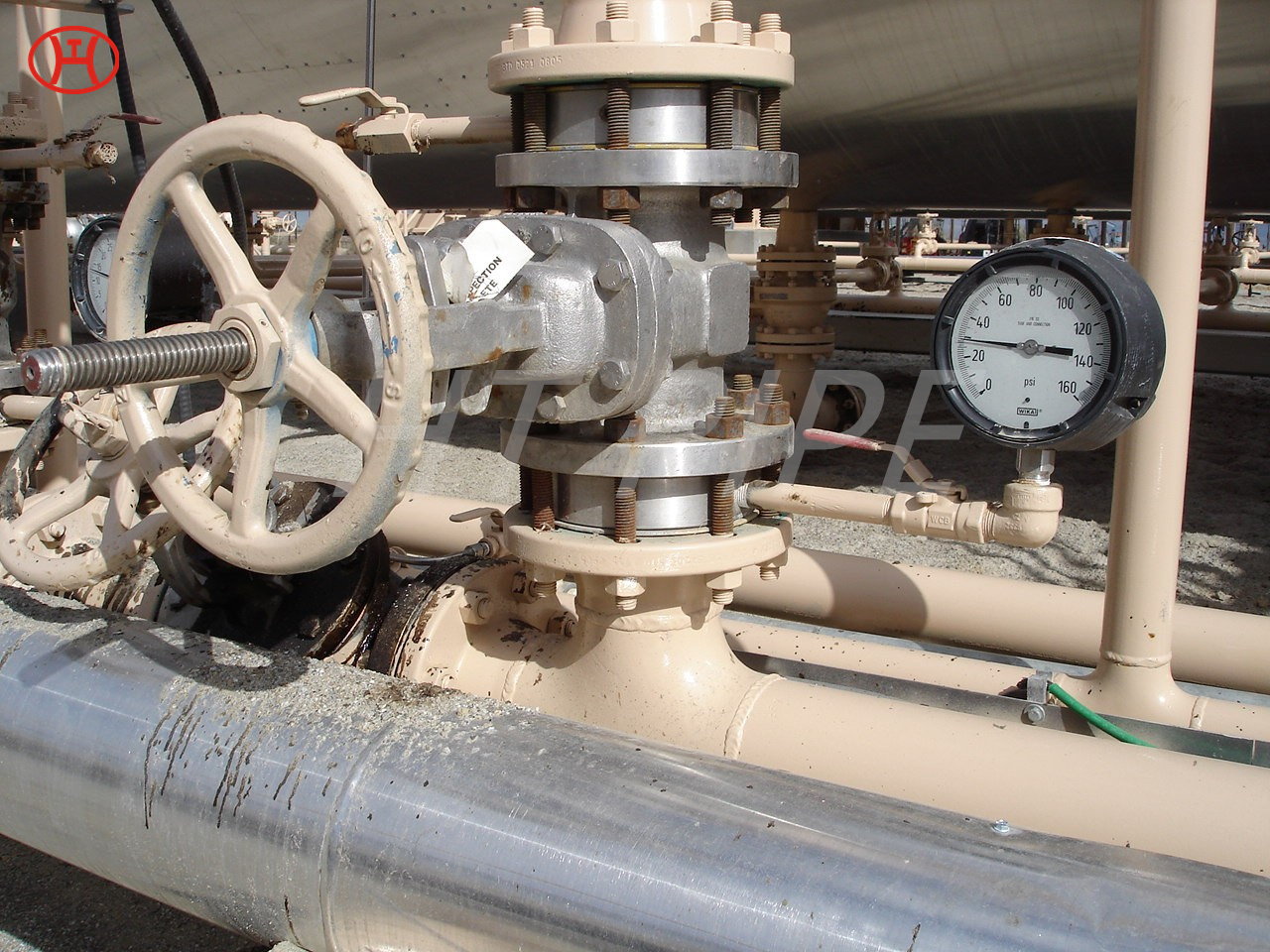

INCOLOY 926 pipe fitting has some corrosion resistance in chloride ions due to localized corrosion properties and 25% content of the nickel alloy. A variety of experiments at 10,000 – 70,000 ppm chlorine concentration, pH 5 – 6, 50 – 68°C operating temperature of limestone desulfurization island slurry showed no crevice corrosion and pitting of 926 alloy during a trial period of 1 – 2 years. INCOLOY 926 pipe fitting also has good corrosion resistance in other chemical media. Corrosion resistance in high temperature, high concentration media, including sulfuric acid, phosphoric acid, acidic gases, seawater, salt and organic acids. In addition, to obtain the best corrosion resistance, regular cleaning is guaranteed.

INCOLOY 926 pipe fitting replaces the conventional, austenitic stainless steel pipe fitting (AISI 316 and 317 pipe fitting), where their capabilities are pushed to their performance limits. The alloy 926, therefore, falls into a “super austenitic stainless steel” category. INCOLOY 926 pipe fitting can also represent a cost-effective alternative to the higher nickel alloys in some marine and chemical processing environments.

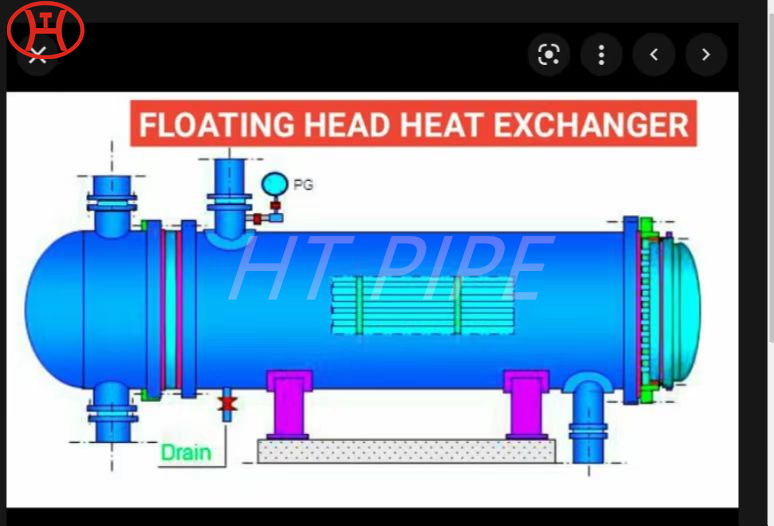

One of the outstanding attributes of INCOLOY 926 pipe fitting is its resistance to environments containing chlorides or other halides. INCOLOY 926 pipe fitting is especially suited to handle high-chloride environments such as brackish water, sea water, caustic chlorides and pulp mill bleach systems. Applications include chemical and food processing, pulp and paper bleaching plants, marine and offshore platform equipment, salt plant evaporators, air pollution control systems, and condenser tubing, service water piping, and feedwater heaters for the power industry.

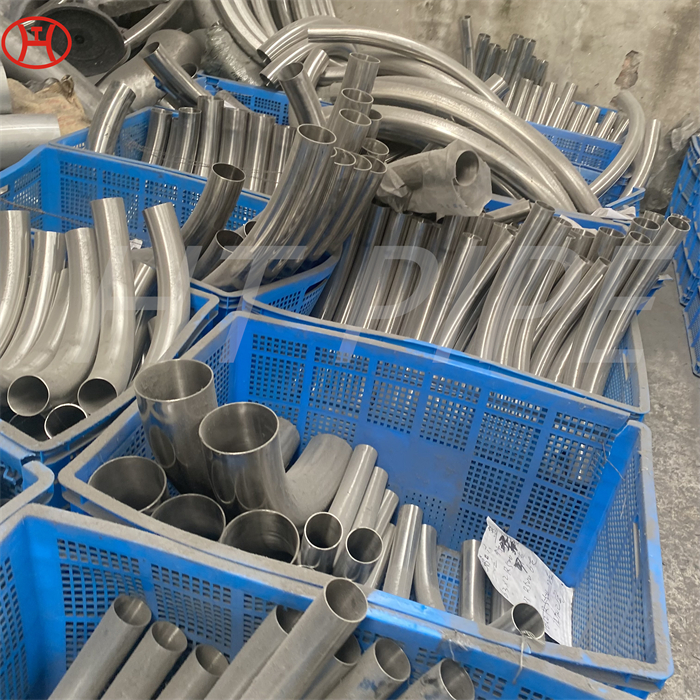

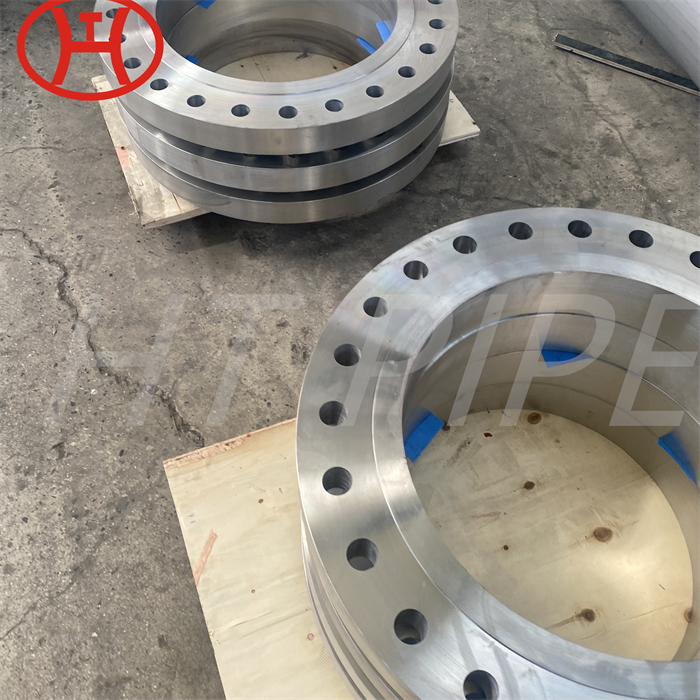

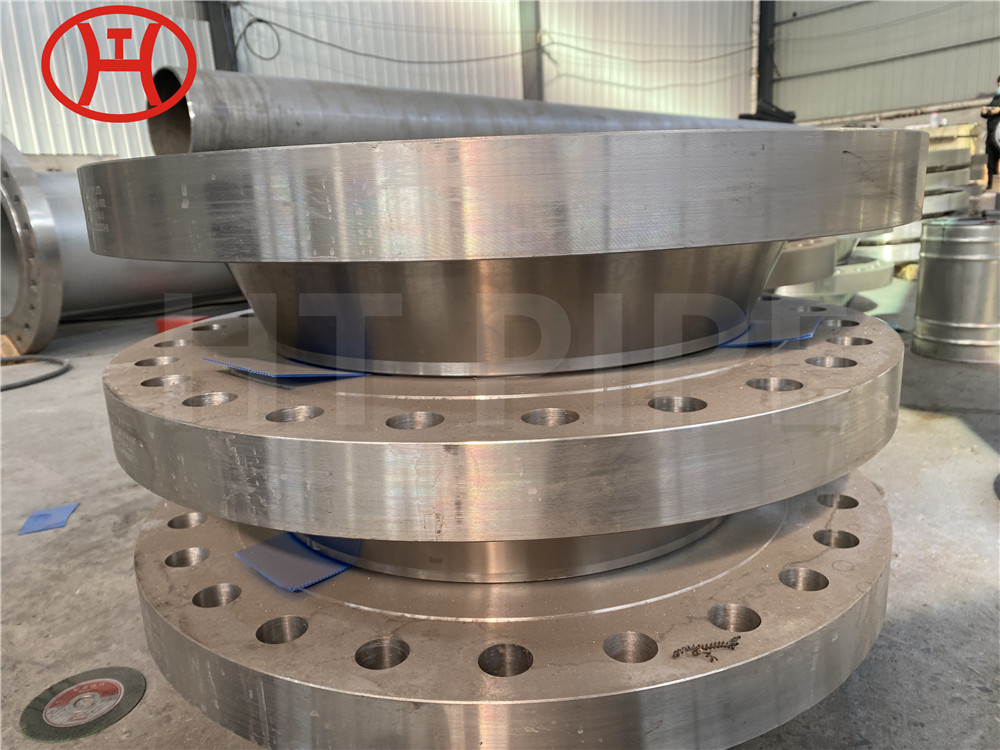

Type Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers

Size OD: 1/2″ ~48″

Thickness: SCH5~SCHXXS

Manufacturing technique£ºpull, push

Producing Standard ASME B16.9 ASME B16.28 ASME B16.49 MSS SP-43 MSS SP-75

Material Nickel Alloy ASTM/ASME SB 366 Alloy 200/UNS N02200, Alloy 800HT/Incoloy 800HT/UNS N08811, Alloy 400/Monel 400/UNS N04400, F904L/UNS N08904, Alloy 800/Incoloy 800/UNS N08800, Alloy C-2000/UNS N06200, Alloy 925/Incoloy 925/UNS N09925, Alloy C-22/UNS N06022, Alloy 201/UNS N02201, Alloy C-276/Hastelloy C-276/UNS N10276, Alloy 625/UNS N06625, Nimonic 80A/Nickel Alloy 80A/UNS N07080, Alloy K-500/Monel K-500, Alloy 20/UNS N08020, Alloy 800H/Incoloy 800H/UNS N08810,Alloy 600/Inconel 600/UNS N06600, Alloy 31/UNS N08031,Alloy 825/Incoloy 825/UNS N08825,Alloy 20/N08020