incoloy alloy 825 pipe N08825 2.4858

Alloy 625 is generally supplied in the annealed condition, to provide utmost stability during fabrication and subsequent service. INCONEL 625 alloy has found to have a resistance to potable and salt or brackish water, where Chloride ions cause pitting and crevice corrosion to become established. As a result, pipelines for gathering sour gas have been built with solid (or clad) INCONEL 625 alloy and used in seawater heat exchangers in refineries, power plants, and offshore topside services that often need this material.

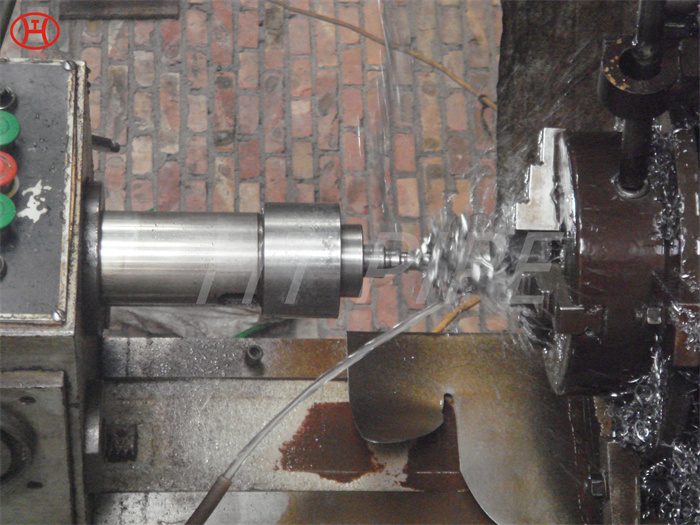

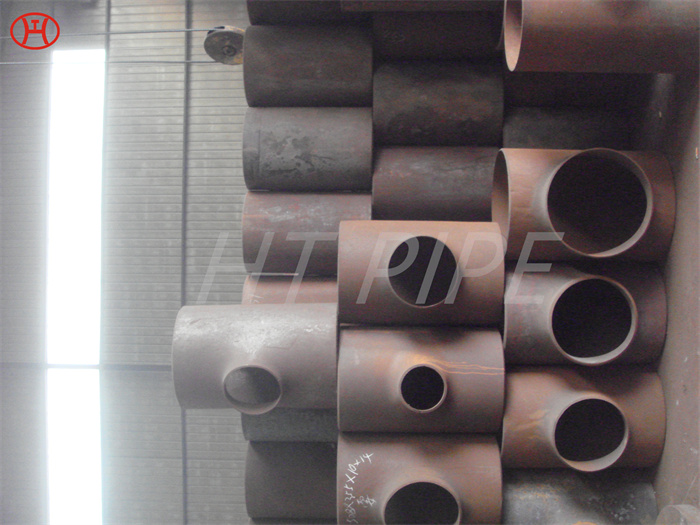

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

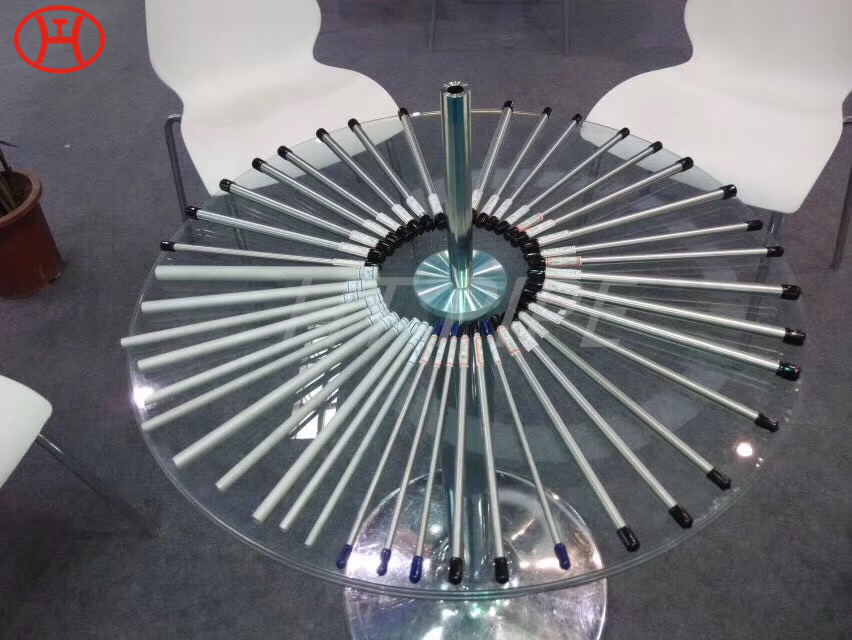

Material Nickel Alloy ASTM B474 UNS N02200/Ni 200, UNS N02201 /Ni201, UNS N04400/ Monel 400, UNS N06002 /Hastelloy X, UNS N06022/ Hastelloy C22, UNS N08825/ Incoloy 825 ,UNS N10276/ Hastelloy C276, UNS N10665 /Hastelloy B2, UNS N10675/Hastelloy B3, UNS N06600/Inconel 600 ,UNS N06601/ Inconel 601 ,UNS N06625 /Inconel 625 ,UNS N08020 /Alloy 20

ASTM B161 UNS N02200/Ni 200, UNS N02201 /Ni233