Inconel 600 Bushing with good oxidation resistance at higher temperatures

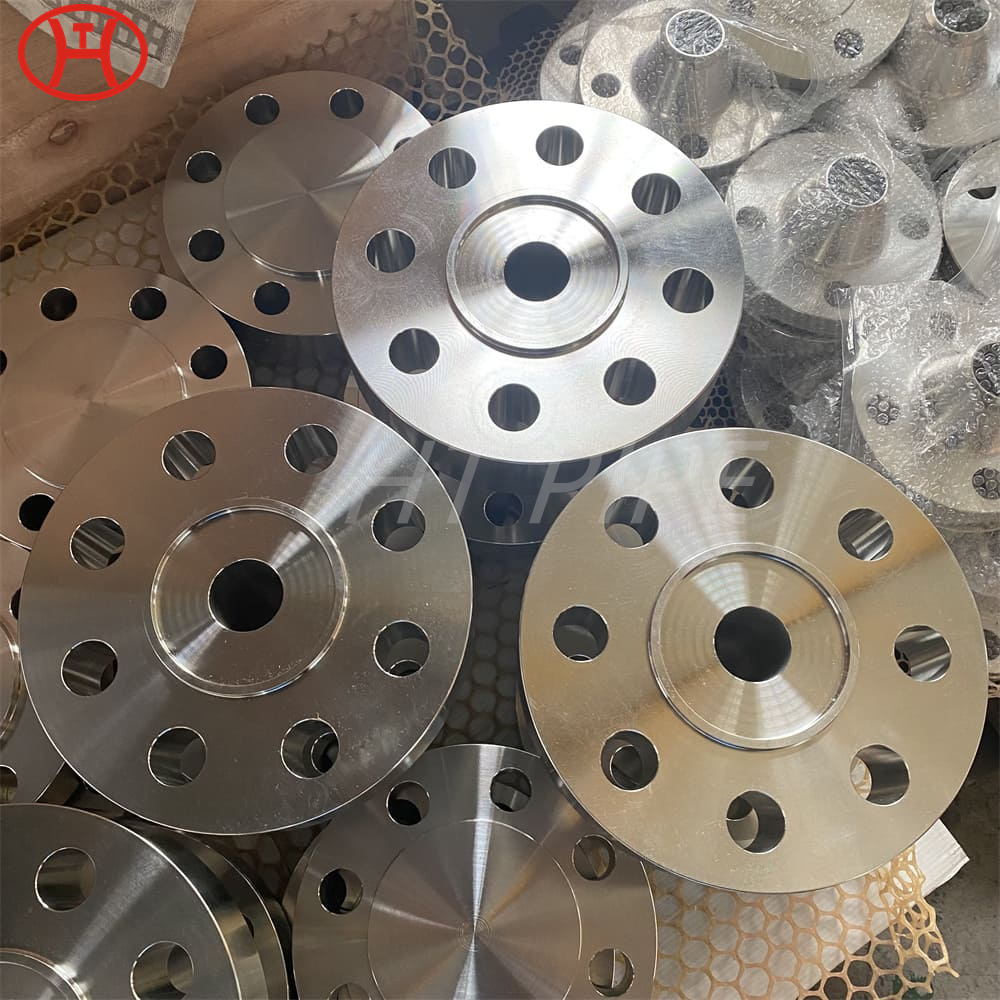

Its typical corrosion applications include titanium dioxide production (chloride route), perchloroethylene synthesis, vinyl chloride monomer (VCM) and magnesium chloride. Alloy 600 is used in chemical and food processing, heat treatment, phenol condensers, soap making, vegetable and fatty acid containers, and more.

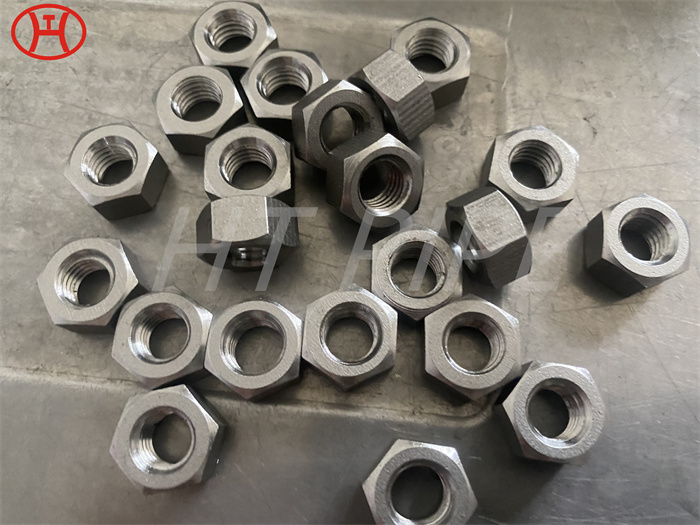

Alloy 600 is non-magnetic, has excellent mechanical properties and a combination of high strength and good machinability, and is easy to weld. Inconel 600 has the cold forming properties typically associated with chrome-nickel stainless steels. Alloy 600 is a non-magnetic, nickel-based superalloy with an excellent combination of high strength, hot and cold workability, and resistance to common forms of corrosion.

This alloy also exhibits good heat resistance and resistance to aging or stress corrosion in conditions ranging from annealing to heavy cold working.