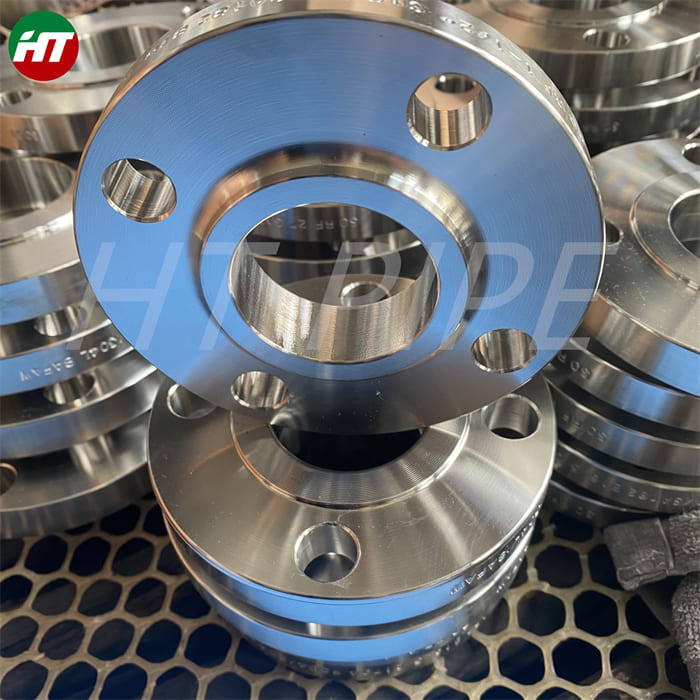

Inconel 600 elbows welded to a weld neck flange and connected to equipment

From the perspective of composition, the high nickel content of INCONEL 600 alloy makes the alloy resistant to corrosion of many organic and inorganic compounds, and makes it almost immune to chloride ion stress corrosion cracking; chromium imparts resistance to sulfur compounds, and in Provides anti-oxidation conditions in high temperature or corrosive solutions.

Alloy 600 can be hot or cold formed using typical processes. Hot working should be performed between 1600¡ãF and 2250¡ãF, avoiding any work between 1200¡ãF and 1600¡ãF as the ductility decreases in this temperature range. The alloy has fair resistance to sulphuric acid at room temperature, but should not be used in this application at elevated temperatures. Resistance to hydrochloric acid is similar to sulphuric acid. The alloy has excellent resistance to phosphoric acid at room temperature in all concentrations, but is rapidly attacked at elevated temperature.