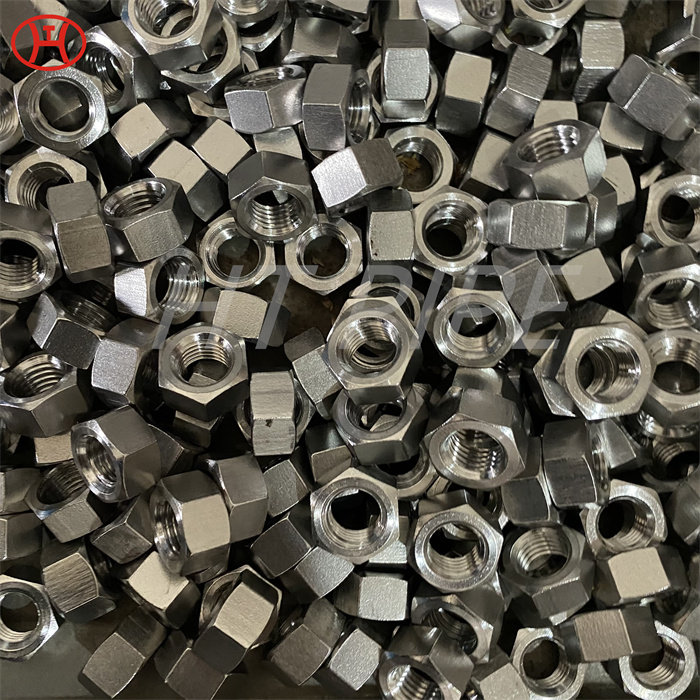

Inconel 600 hex nuts UNS N06600 nuts for general corrosion resistance

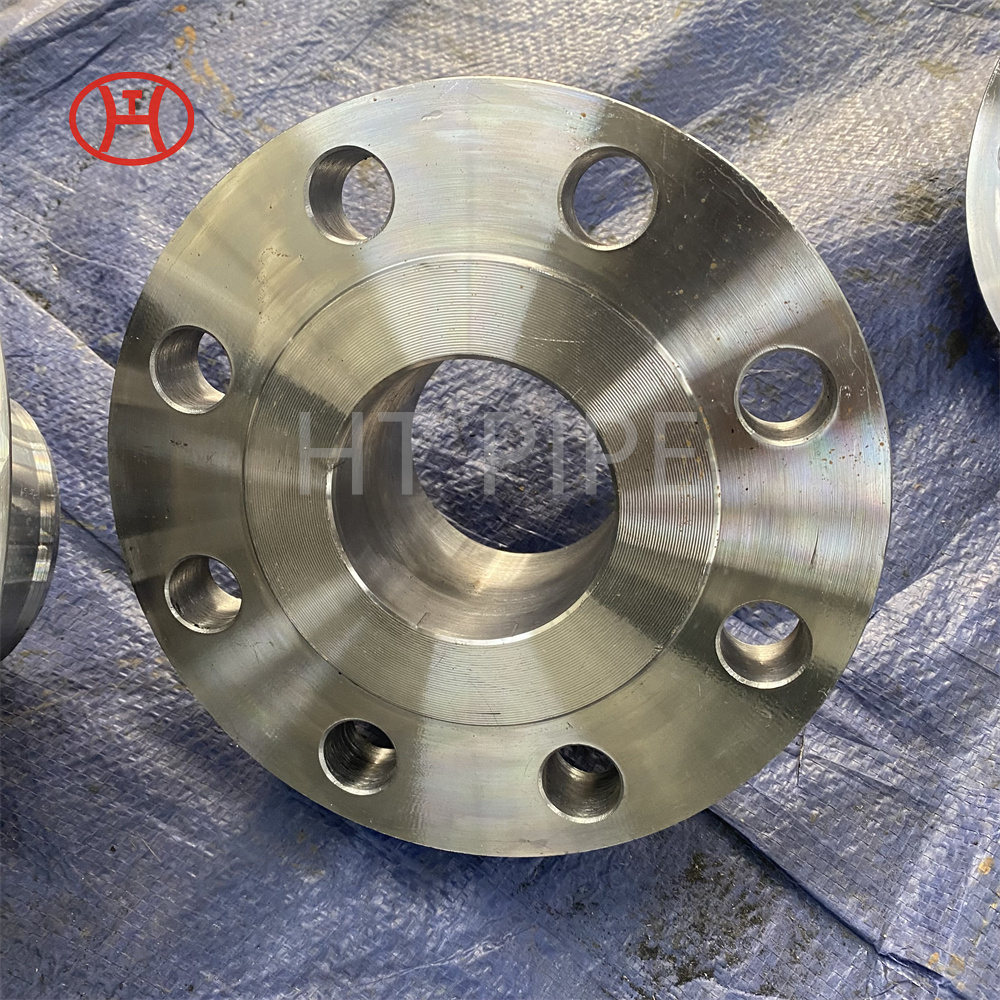

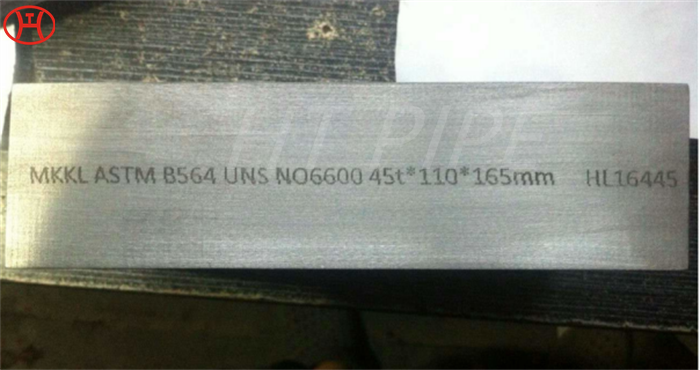

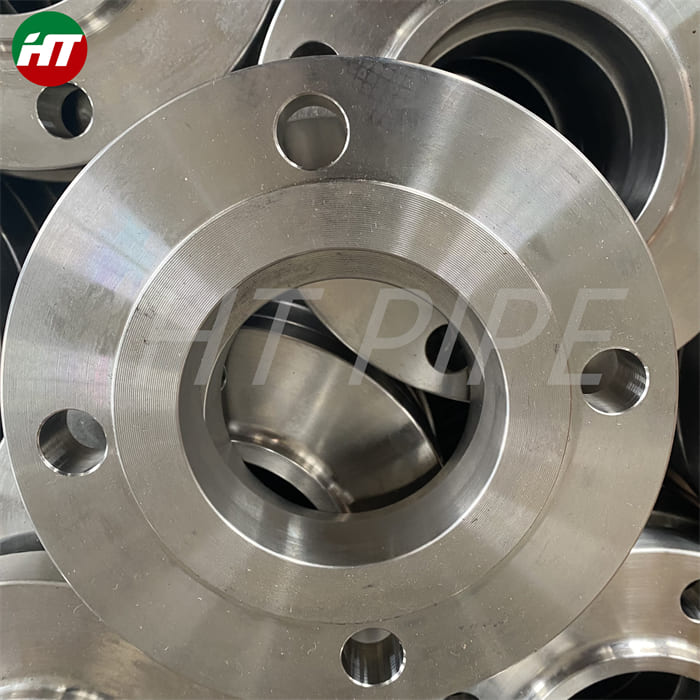

Because of its versatility, and because it is the standard engineering material for applications which require resistance to corrosion and heat, a number of different critical industries use Nickel Alloy 600 in their applications. It is an superior choice for Nuclear reactor vessels and heat exchanger tubing and Chemical processing equipment. Alloy 600 can be provided in the lower strength, annealed condition, or strengthened through the pilger process.

Alloy 600 maintains excellent toughness even in the higher strength conditions and maintains toughness at cryogenic temperatures. Nickel Alloy 600 and Inconel 600 are readily fabricated (hot or cold) and can be joined using standard welding, brazing, and soldering processes. While Alloy 400 cannot be strengthened by heat treating, annealing or stress relieving are commonly used after hot working or cold working operations. Stress-relieving is conducted at 1400¡ãF – 1600¡ãF (760¡ãC – 871¡ãC).