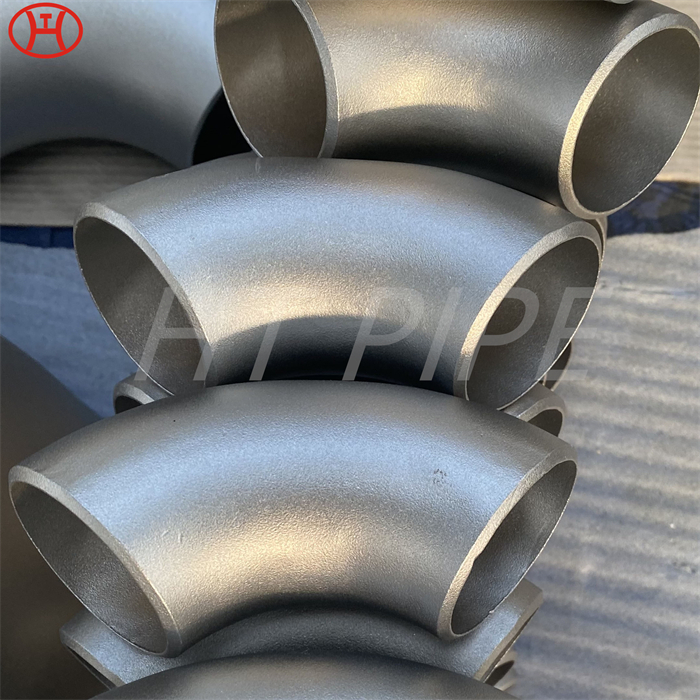

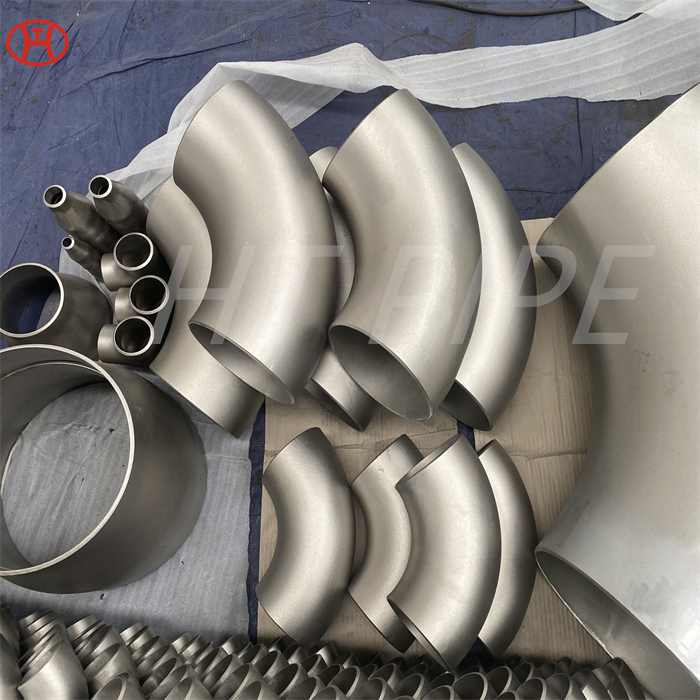

Inconel 601 bw elbow provides resistance to carburization is good, also resistant to carbon nitriding conditions

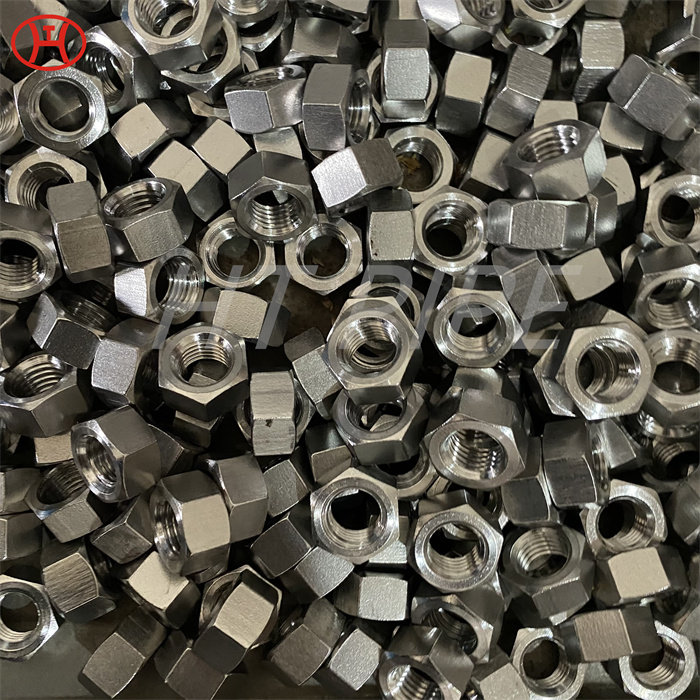

Inconel 601 ( UNS N06601 ) nickel-based alloy Elastic modulus: 124.7-206.5GPa.

Inconel 601 ( UNS N06601 ) nickel-based alloy gold melting point: 1360-1411¡ãC. Inconel 601 (UNS N06601) nickel-based alloy is not a precipitation hardening platform metal, therefore, it cannot be age hardened by heat treatment. After cold working, when the temperature reaches about 900¡ãC, the material will soften. If the material has high temperature strength, it is recommended to perform solution heat treatment at a temperature of 1100 ~ 1200¡ãC. At this time, the cooling method is water cooling, and air cooling can also be used according to the thickness of the plate. However, in order to avoid carbide precipitation, it is recommended to cool as quickly as possible in the temperature range of 500 ~ 800 ¡ãC.