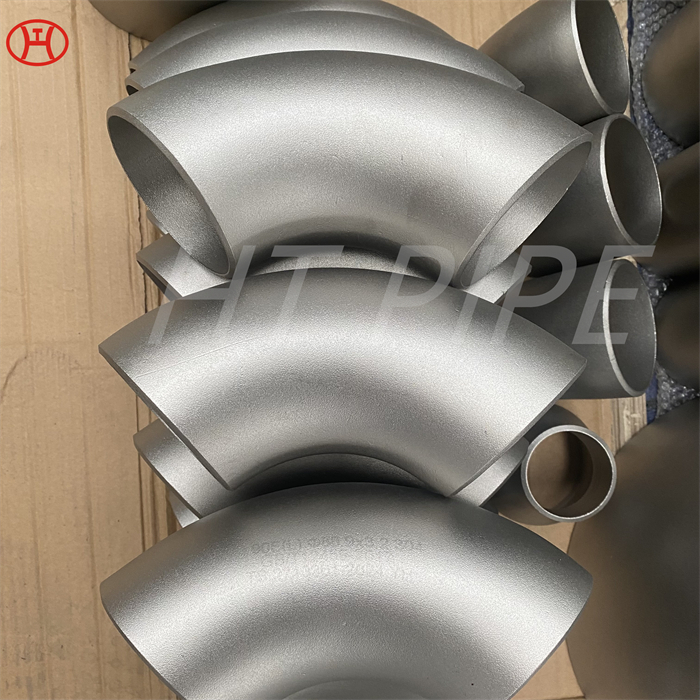

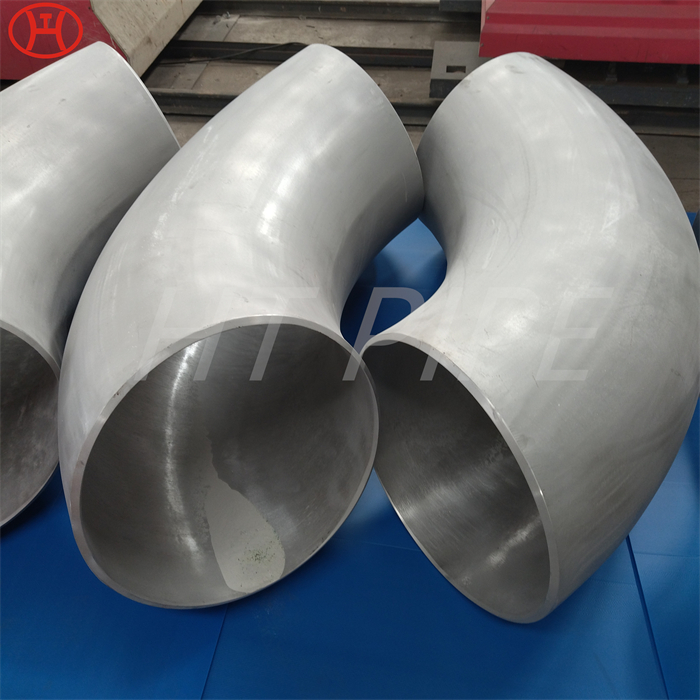

Inconel 601 bw elbow with provides resistance to many corrosive media and high-temperature environments

Inconel 601 (N06601) nickel-based alloy plasticity:

Inconel 601 (UNS N06601) nickel base alloy is relatively easy to hot work. The heating temperature is 1150~1200C, and the thermal processing temperature is

1050~1200C, simple processing can be carried out below 850¡ãC.

Cracking will occur in the temperature range of 650~850C, please avoid this temperature zone

between processing. Regarding cooling after hot working, in order to avoid carbide precipitation, it is recommended to increase the cooling rate in the range of 500~800¡ãC.

Delivery status: seamless pipe: solid solution + acid white, the length can be customized; plate: solid solution, pickling, trimming; welded pipe: solid solution acid white + RT% probe

Wounds, forgings: annealing + lathing; bars are delivered in forged state, surface polished or lathed; strips are delivered in cold-rolled, solution-soft state, descaled;

Solid solution pickling disc or straight strips, solution straight strips are delivered in a finely polished state.