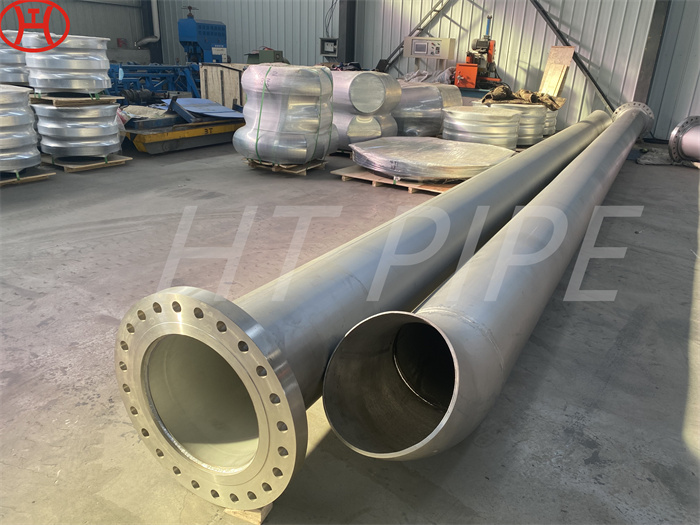

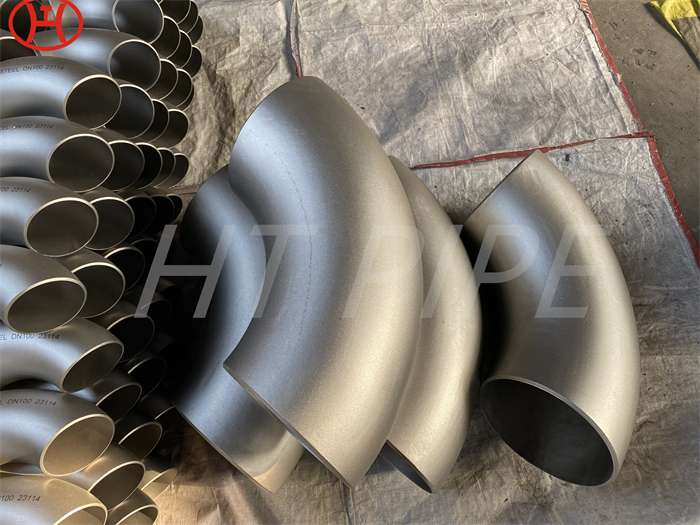

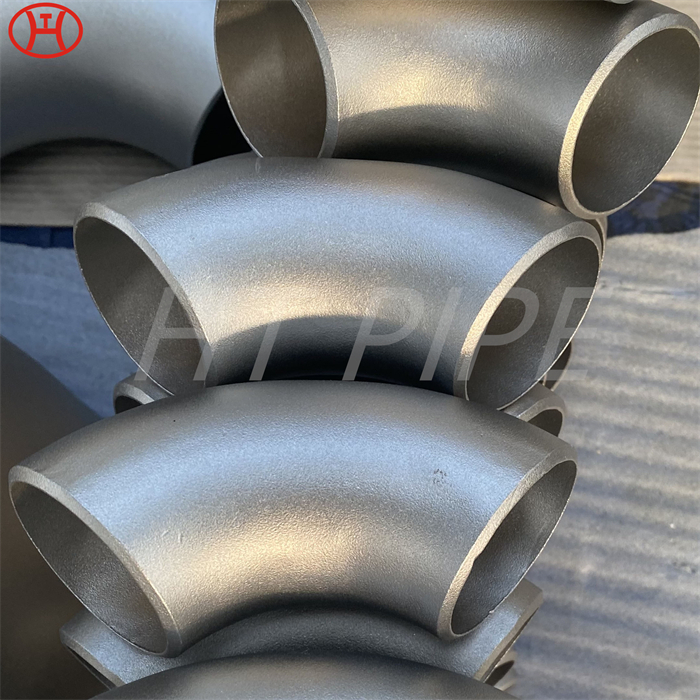

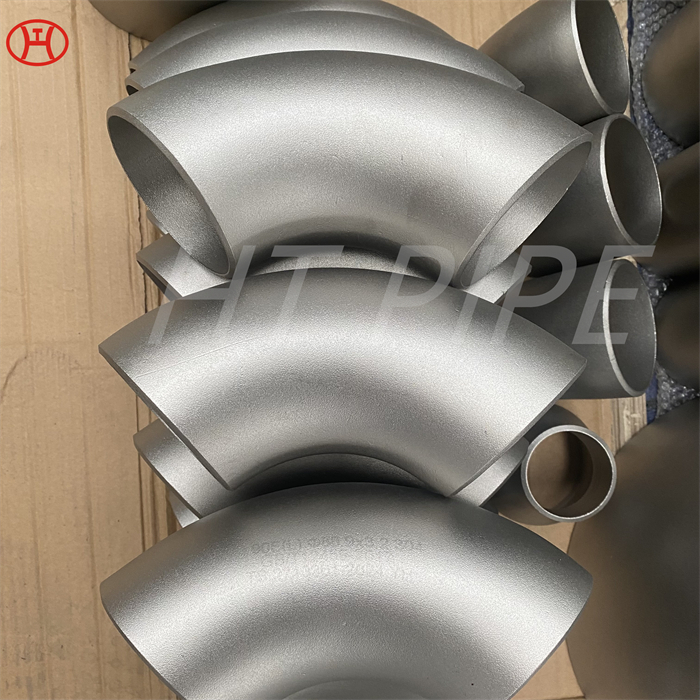

Inconel 625 2.4856 pipe and spool drawings for unusual severity

It is used for components that require exposure to sea water and high mechanical stress.

Contact US

Get Price

Share:

Content

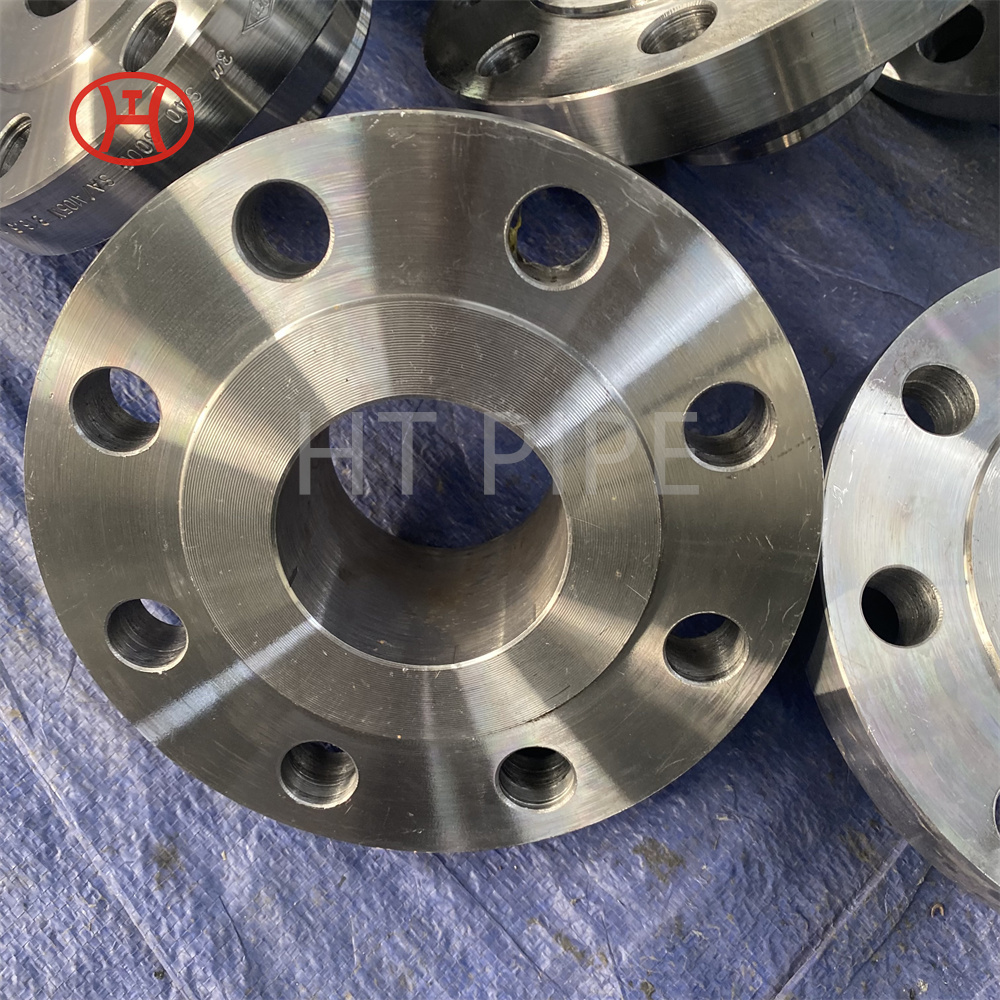

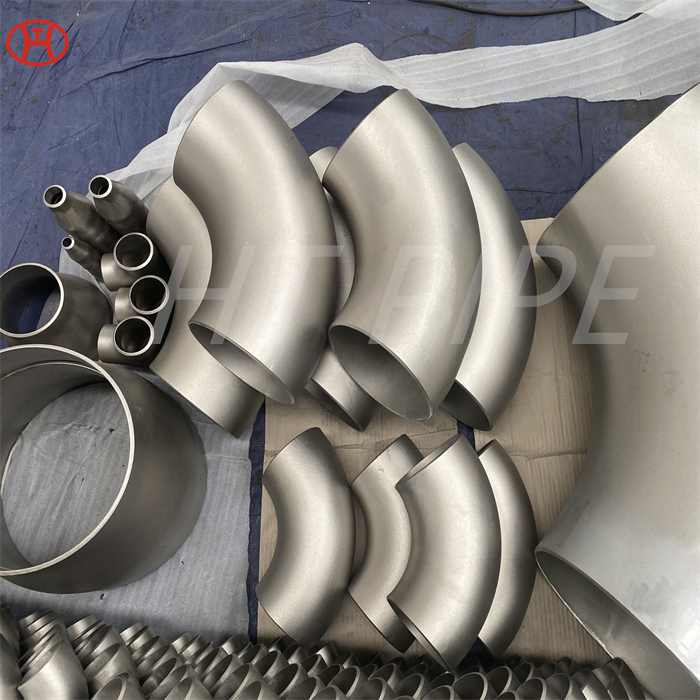

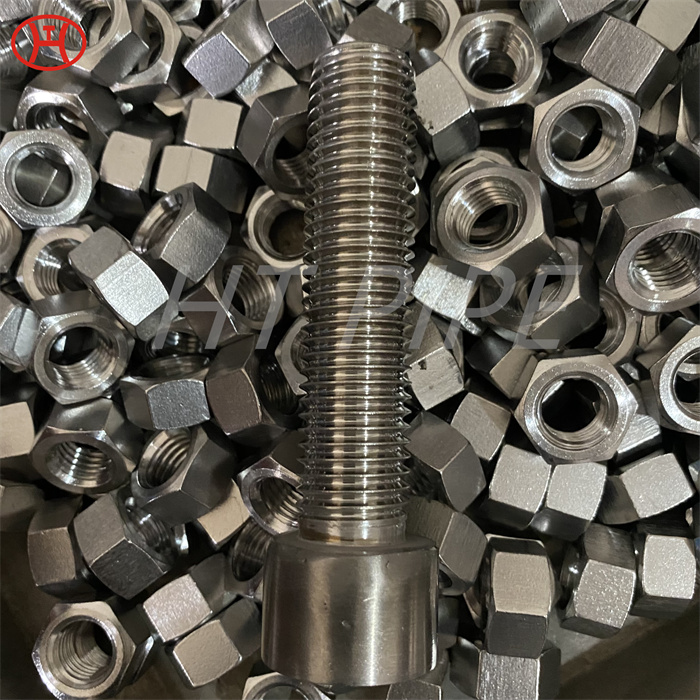

It is also used in oil and gas production in the presence of hydrogen sulfide and elemental sulfur at temperatures in excess of 150C. Typical end use applications include heat exchangers, bellows, expansion joints, exhaust systems, fasteners, quick connect fittings and many other applications requiring strength and resistance against aggressive corrosive environments. Alloy 625 is a nickel-chromium-molybdenum alloy with additional of niobium. This provides a high strength alloy without a strengthening heat treatment.

Inquiry

More Inconel