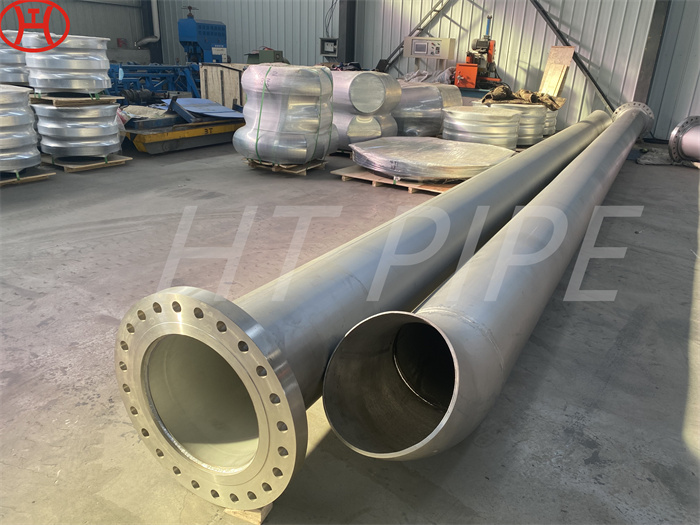

Inconel 625 elbows at a bend of 45 degree or 90 degree

The strength of Inconel 625 lies not only in its nickel-chromium base but also the hardening mechanism of niobium and molybdenum.

Alloy 625 elbow has good resistance to oxidation and scaling at high temperatures. At 1800¡ãF, scaling resistance becomes a significant factor in service. It is superior to many other high temperature alloys under cyclic heating and cooling conditions. The combination of the alloyed elements in alloy 625 elbow enables it to withstand a wide variety of severe corrosive environments. There is almost no attack in mild environments, such as fresh and seawater, neutral pH environments, and alkaline media. The chromium content of alloy 625 elbow results in superior resistance to oxidizing environments. The high molybdenum content makes alloy 625 very resistant to pitting and crevice corrosion. Alloy 625 elbow can be formed using various cold and hot working processes. Alloy 625 resists deformation at hot working temperatures, therefore higher loads are required to form the material.