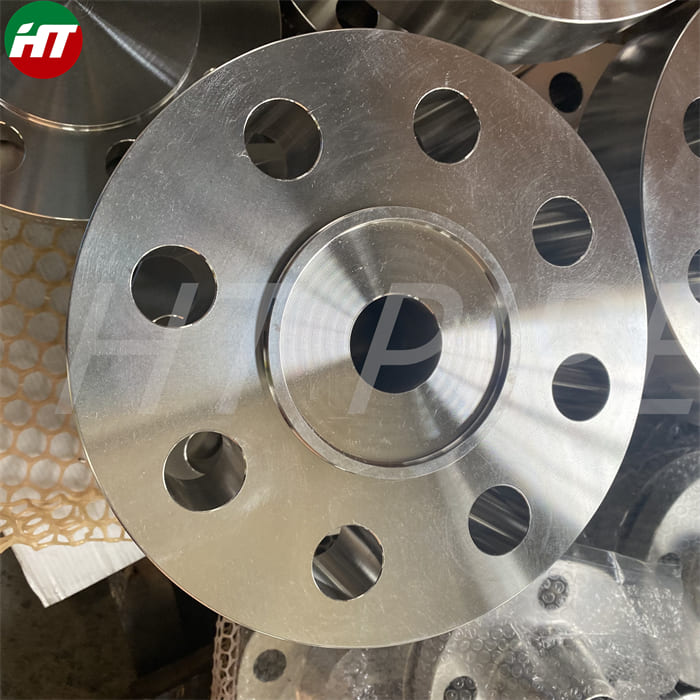

Inconel 625 elbows for equipment used in petroleum and fluid power

Owing to its high corrosion resistance– especially pitting and crevice resistance, Inconel 625 is an ideal for high saline, underwater applications.

Inconel 625 has corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water, neutral salts and alkaline media there is almost no attack. In more aggressive media nickel and chromium resist oxidising attack, while nickel and molybdenum resist reducing environments. Inconel 625 achieves reasonably high strength through the addition of molybdenum and niobium to the nickel-chromium base, but nowhere as high as Inconel 718. However, due to the high level of chromium and molybdenum it is corrosion resistant in the most aggressive of environments. Inconel 625 is a non-magnetic, corrosion and oxidation resistant, nickel-chromium alloy. This material can be used because of its high strength, excellent uniform corrosion resistance, resistance to stress cracking and excellent pitting resistance in 500¡ã-600¡ãF (260-316¡ãC) water.