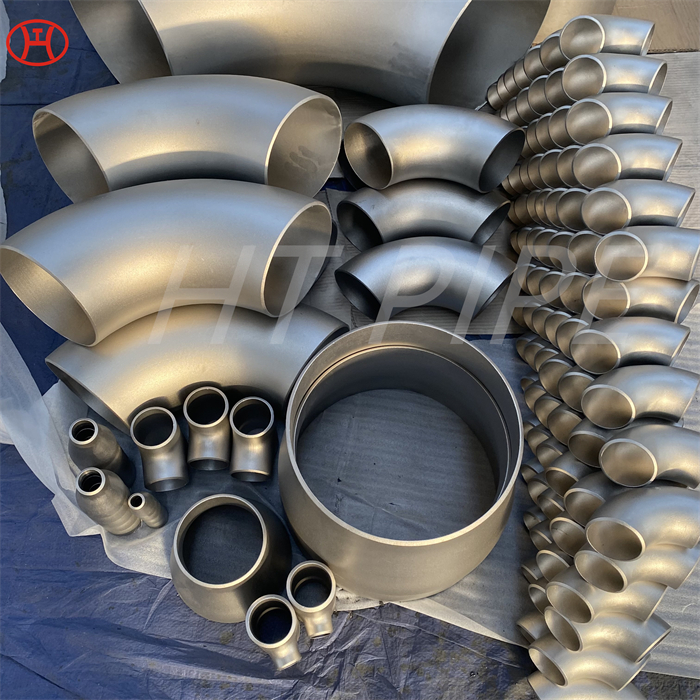

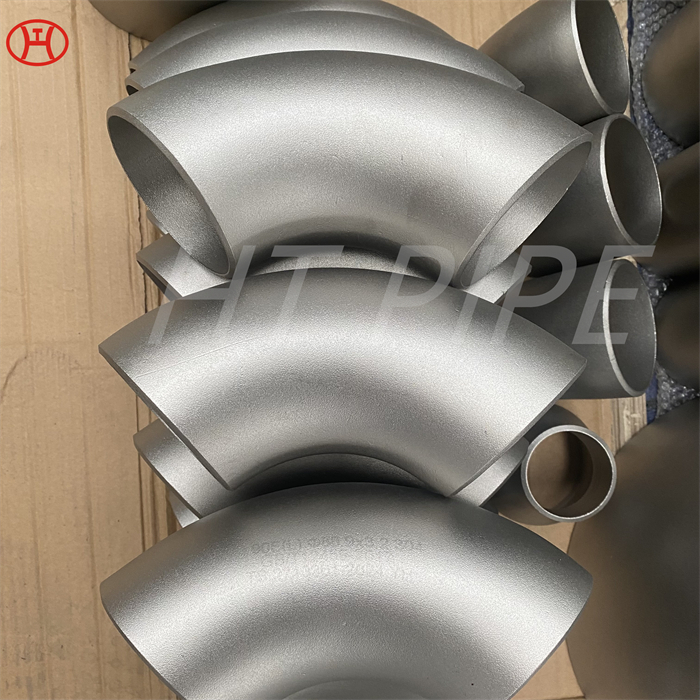

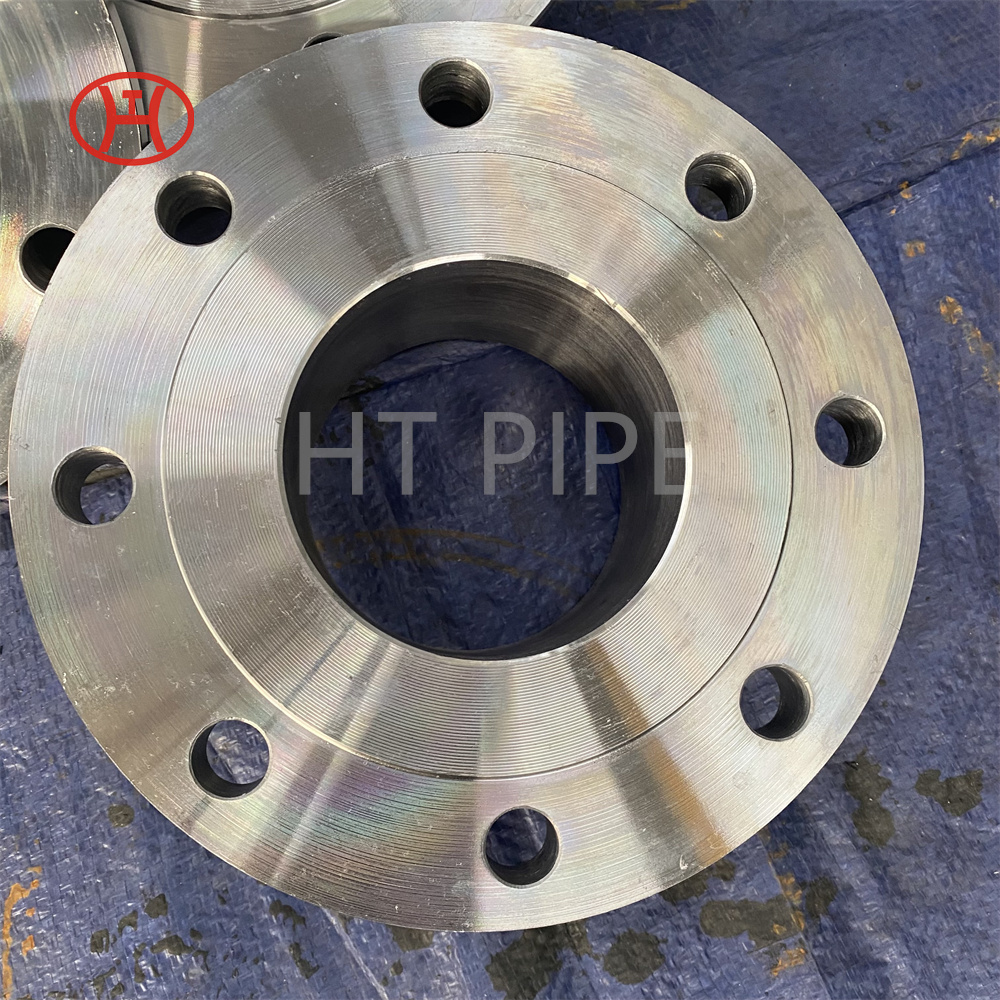

Inconel 625 elbows for rigid applications like extreme low temperature resistance

Upon exposure to oxidising agents, Inconel 625 is protected naturally by its nickel-chromium matrix.

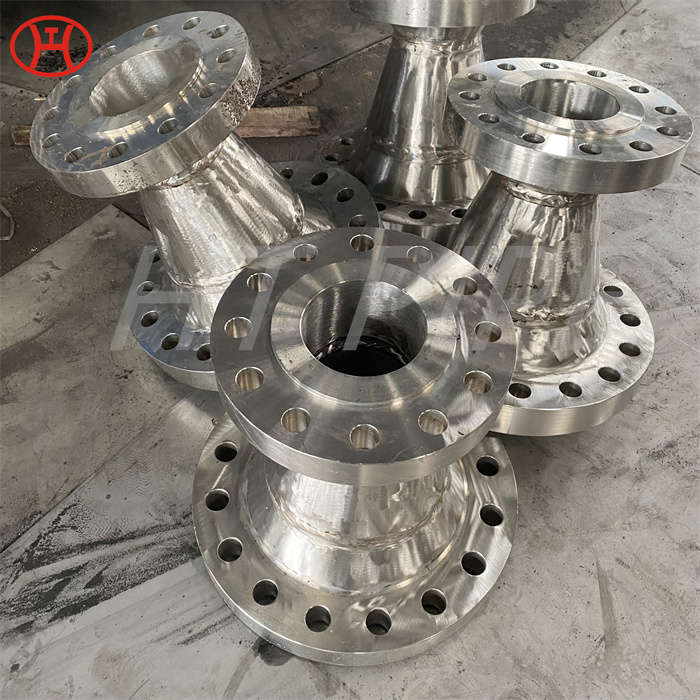

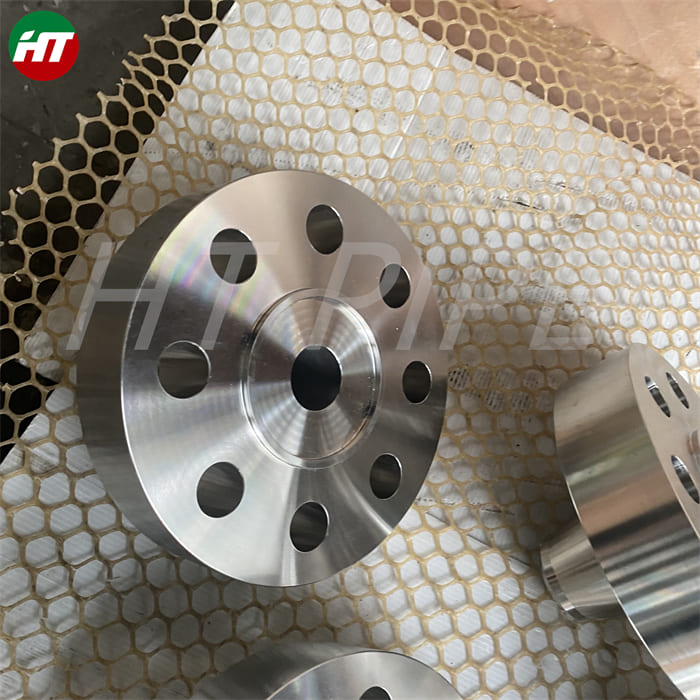

Inconel 625 elbow is used in aerospace applications as well as marine applications. Common applications for this alloy are springs, seals, bellows for submerged controls, electrical cable connectors, fasteners, flexure devices, and oceanographic instrument components. In order to restore the best balance of properties, all hot or cold worked parts should be annealed and rapidly cooled. This nickel alloy can be welded by both manual and automatic welding methods, including gas tungsten arc, gas metal arc, electron beam and resistance welding. It exhibits good restraint welding characteristics. Within in these critical industries you can find Nickel Alloy 625 and Inconel 625 in various applications including:

Nuclear reactor-cores and control-rod components

Wire rope for cables and blades on Naval crafts such as gunboats and subs

Oceanographic equipment