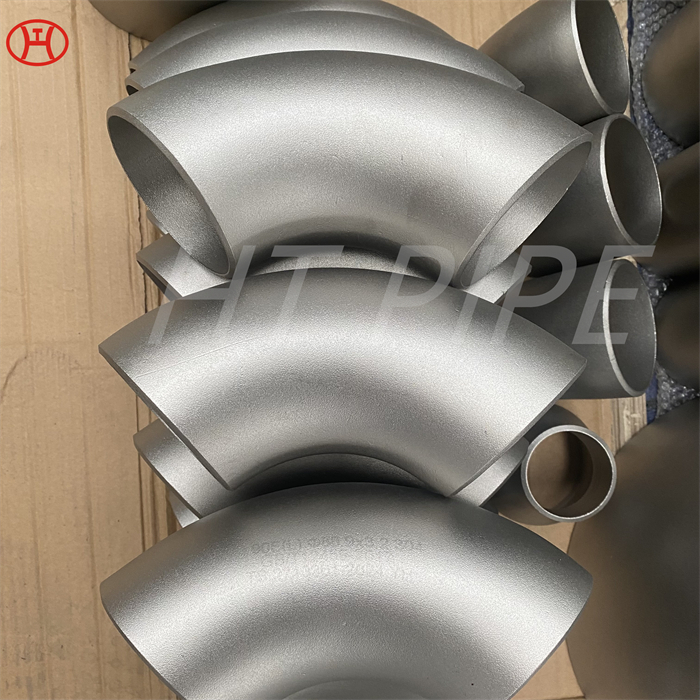

Inconel 625 elbows manufactured to be used in flow lines for gases

At high temperatures in the presence of oxidising agents, the titanium and niobium compositions of the oxide film on Inconel 625 increase drastically to form a natural protective layer in the material.

Alloy 625 elbow has versatile resistance to corrosion which is outstanding, even in severely corrosive environments. The material also shows superior resistance to high-temperature effects such as oxidation and carburization. It is an excellent choice for seawater and sour gas applications. Inconel 625 is a high strength, highly corrosion resistant nickel-chromium-molybdenum alloy used in applications in the aerospace, oil and gas, automotive, marine, chemical processing and nuclear industries where strength at high temperature are required. Inconel 625 elbow is a nickel-chromium based superalloy that is extremely resistant to corrosion and strong at high temperatures. It¡¯s easy to print, enabling you to fabricate functional prototypes and end-use parts designed for harsh environments.