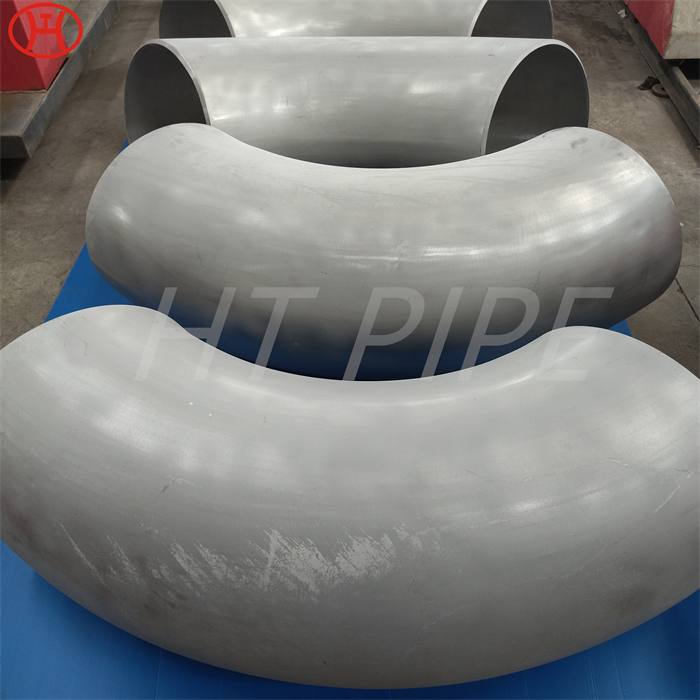

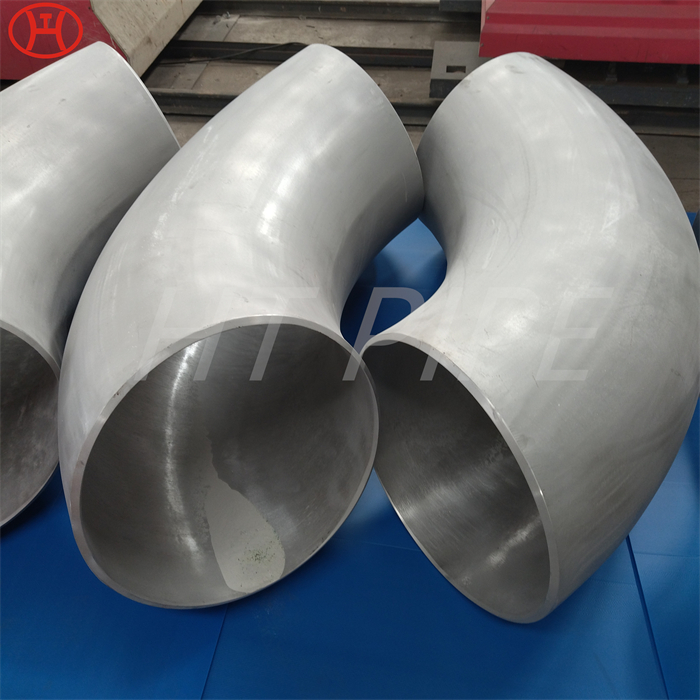

Inconel 625 elbows of ASTM EN DIN GB ISO JIS Standard

Nuclear systems also generally involve high temperatures beyond 650¡ãC, in which the strength of Inconel 625 elbow can withstand.

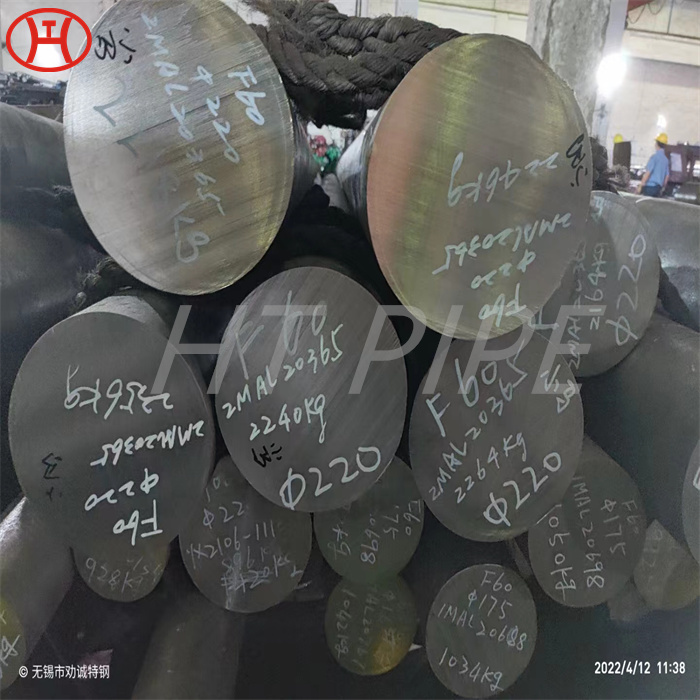

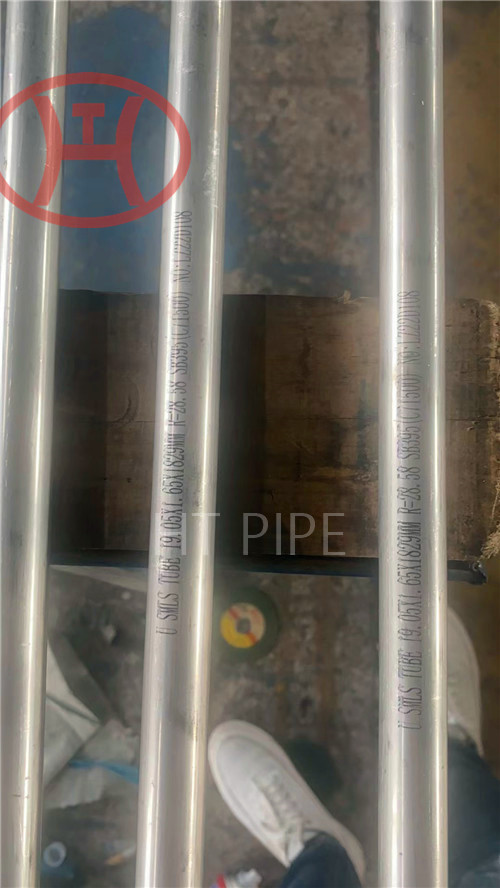

Alloy 625 (UNS N06625) is a very forgeable nickel alloy. Inconel? 625 be forged into seamless rolled rings and simple part shapes via open die forging applications, including bars and blocks, disks, stepped-shafts, and other simple open-die shapes. Inconel 625 is difficult to machine (class D-2). Heavy machines, sharp tools, slow speeds and deep uninterrupted cuts to remove the work hardened layer are needed. Inconel 625 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Inconel 625 is annealed at 925¨C1040¡ãC, cooling rate not critical. Solution anneal at 1090¨C1200¡ãC. Stress relief, if required, is at 590¨C760¡ãC, or up to 870¡ãC for complete relief.