Inconel 625 Pipe Price Alloy 625 Seamless Tubing

ASTM B444 Inconel 625 ERW Pipe has excellent resistance to intergranular corrosion and intergranular stress corrosion cracking, and is mainly used as a heat transfer tube material for steam generators in pressurized water reactor nuclear power plants.

High quality polished Inconel 625 Seamless Pipe, ASTM B444 Inconel 625 ERW Pipe ASME B36.19, check price of Inconel Din 2.4856 Welded Pipe in China.

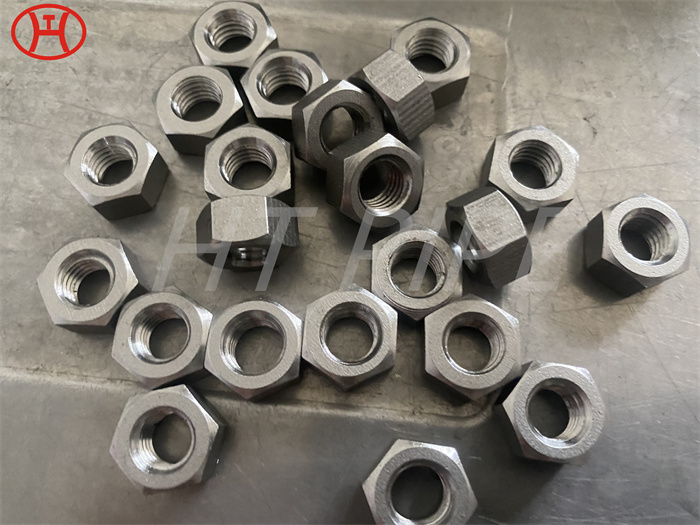

Inconel 625 is a high performance nickel-chromium-molybdenum alloy known for its high strength, temperature and corrosion resistance. ASTM B444 Inconel 625 ERW Pipe is primarily composed of nickel (at least 58%), followed by chromium, molybdenum, niobium, iron, tantalum, cobalt, and trace amounts of manganese, silicon, aluminum, and titanium. ASME B36.19 Alloy 625 / Inconel 625 pipe is used for its high strength, excellent machinability (including joining) and excellent corrosion resistance. Inconel Din 2.4856 Welded Pipe has become a standard material of construction in a variety of industrial applications, which is unusual for an alloy. Inconel 625 is a high strength, high corrosion resistant nickel-chromium-molybdenum alloy used in aerospace, oil and gas, automotive, marine, chemical processing and nuclear industries where high temperature strength (between 1200°F – 1400°F) is required ).

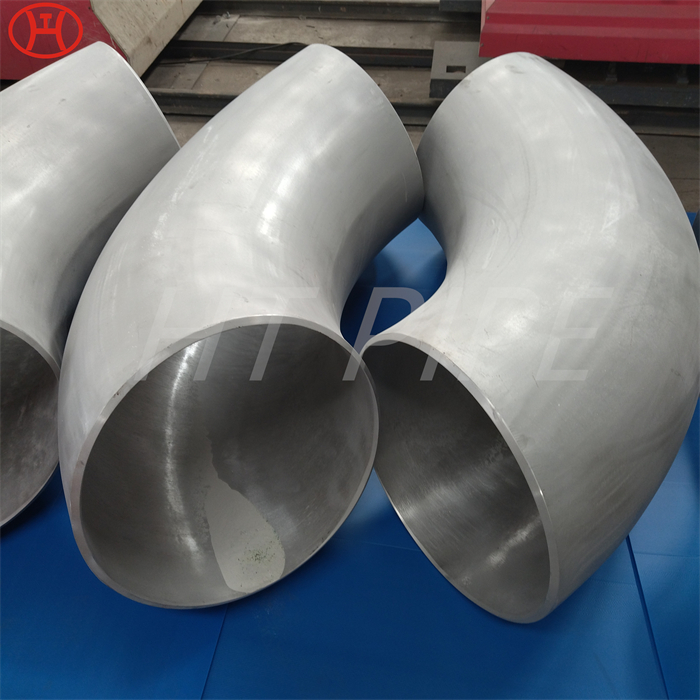

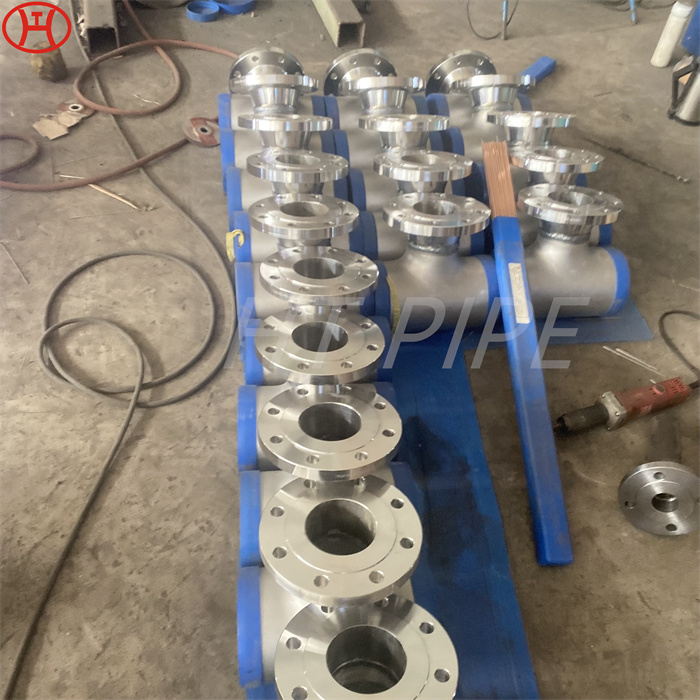

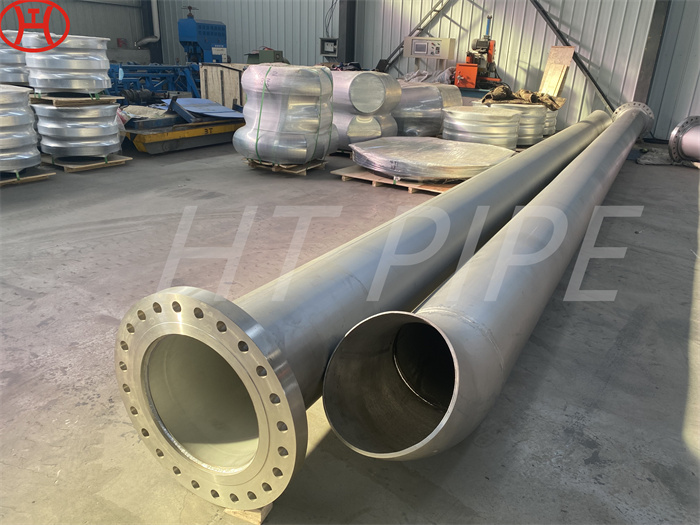

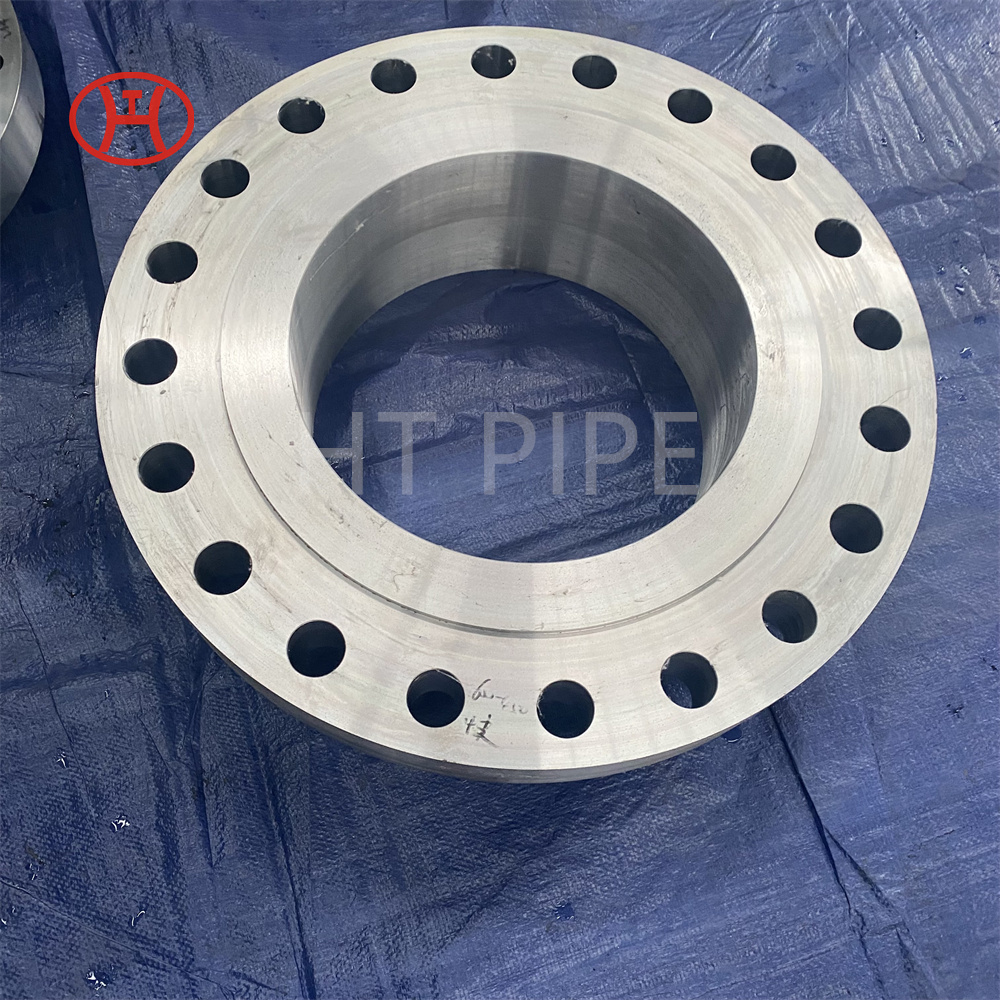

Alloy 625 Seamless Tubing is used in high stress applications at elevated temperatures. The Inconel 625 Tube can be used in heat exchangers, condensers and in boiler components for this reason. The UNS N06625 Tubes come under the ASTM B167, ASTM B829 and ASTM B517 specifications. The dimensions range according to ASTM, ASME and API standards. A high strength, nickel-based alloy, Inconel 625 exhibits excellent corrosion resistance, oxidation resistance, and toughness. It has very high fatigue strength, is nonmagnetic, and offers an operational temperature range from cryogenic to 2,000°F (1,093°C). The Alloy 625 Seamless Tubing comes in sizes ranging from 4mm to 219mm. There are welded, fabricated and LSAW pipes as well. The welded and EFW pipes range from 5mm to 1219.2mm in size. The wall thickness of the Inconel 625 Seamless Pipe ranges from 0.5mm 20mm. The UNS N06625 pipes are specified for larger diameters with schedules ranging from 5 to 160. The pipes come in different forms such as round and hydraulic pipes. The lengths of the pipes vary as single random, double random and cut to lengths. The ASTM B444 UNS N06625 ERW Pipe is made up of a procedure known as electric resistance weld. The pipes also come with different ends such as treaded, beveled end and plain ends. Please contact us for more information on the products such as the Inconel Din 2.4856 Welded Pipe and other types and their prices.

Alloy 625 Seamless Tubing Specification Schedule

| Specifications | ASTM B 167 ASME SB 167 / ASTM B 829 ASME SB 829 / ASTM B 517 ASME SB 517 |

| Dimensions | ASTM, ASME and API |

| Seamless 625 Pipe | 4 to 219mm W. T.: 0.5 to 20mm |

| Welded 625 Pipe | 5.0 mm – 1219.2 mm |

| EFW 625 Pipe | 5.0 mm – 1219.2 mm |

| Size | 15″NB TO 150″NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |