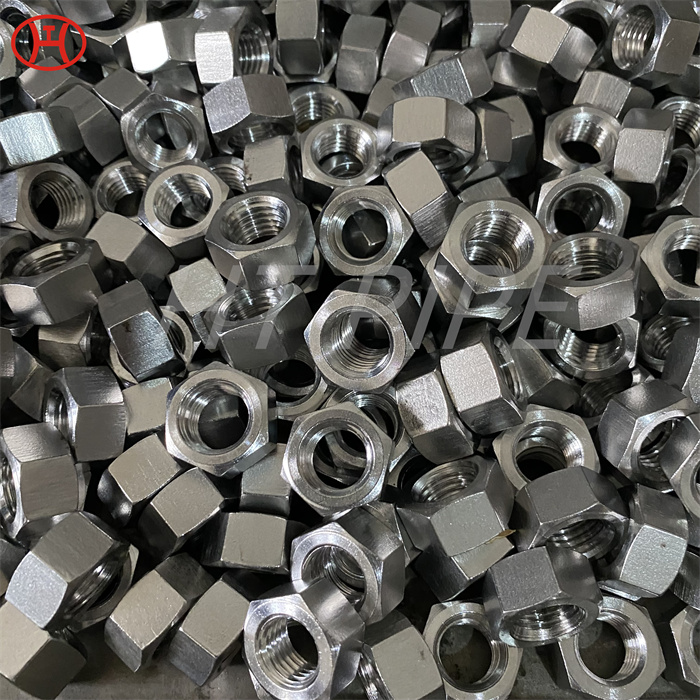

Inconel 625 round bar High creep-rupture strength

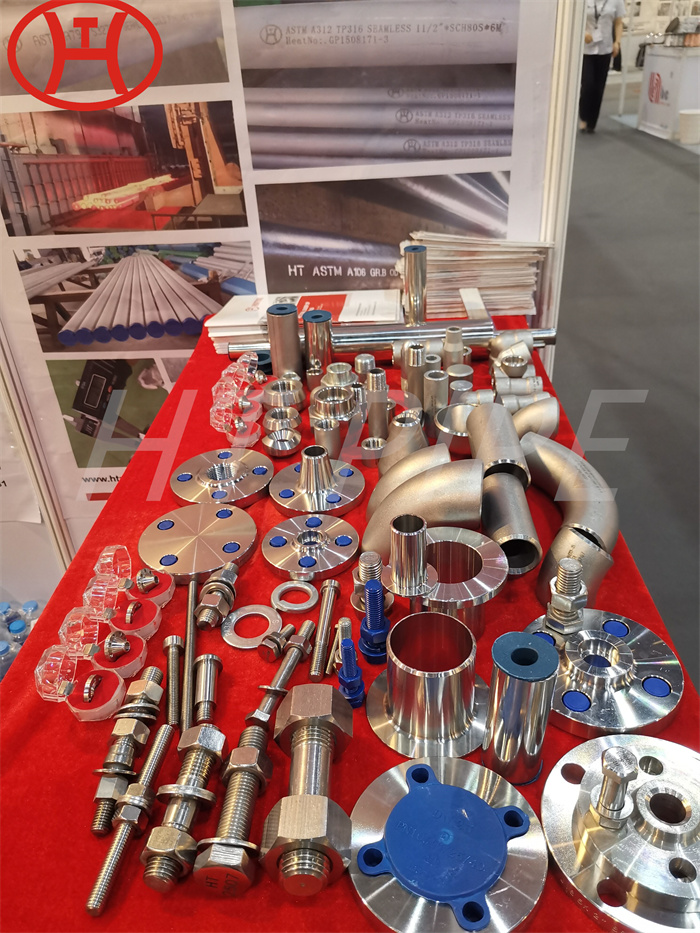

Inconel 625 round bars are also used in nuclear reactors, combustion systems, rocket thrust chamber tubes, transition liners, compressor blades, turbine seals, and more. It has excellent formability and solderability due to its high nickel content. 625 Round Bar has excellent resistance to a variety of acidic environments such as nitric, sulfuric, hydrochloric and phosphoric environments. In addition, they provide protective properties, surrounded by alkali metals.

Nickel alloys are very versatile materials, and their use extends to various fields. While Nickel Alloy 625 round bars are known for their excellent heat resistance, this alloy is also appreciated for its performance at low temperatures. The low temperature is extremely low and the environment is very cold. Unlike Inconel UNS N06625 Hex Bar, these climatic changes can easily damage ordinary rebar.

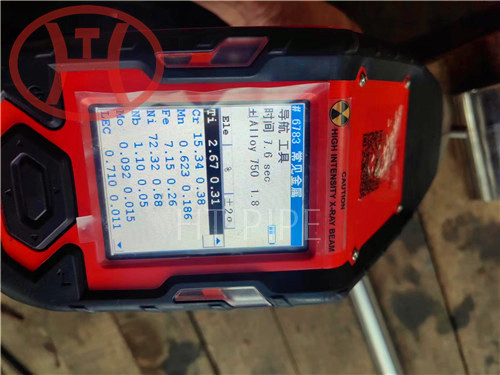

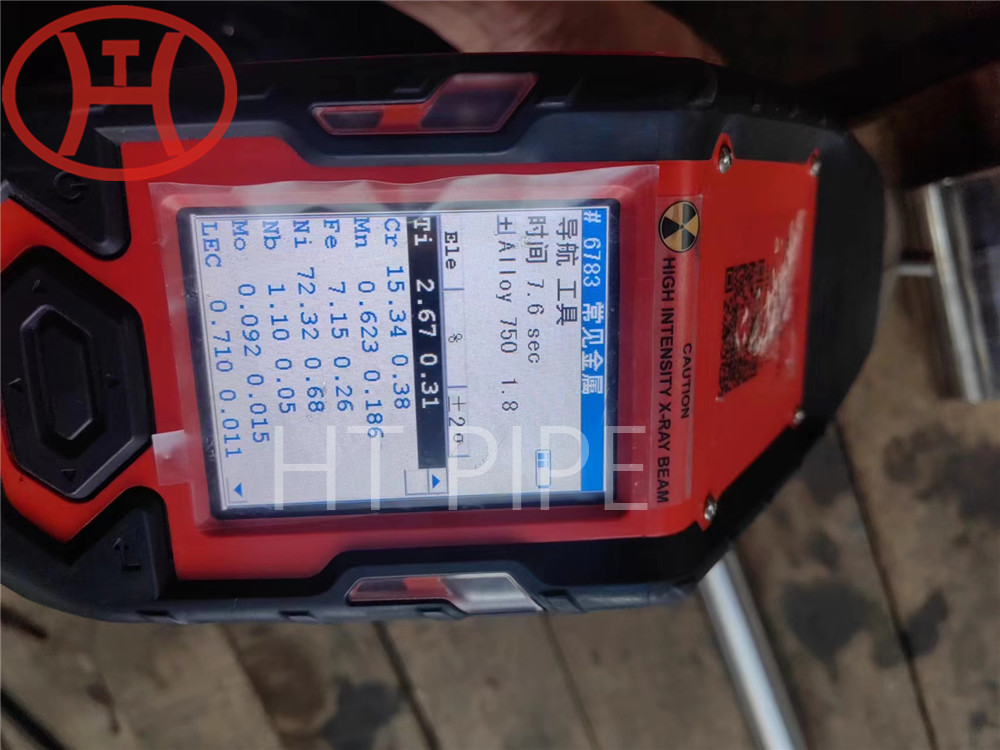

Nickel in Inconel 625 Din 2.4856 Polishing Rods gives the alloy corrosion resistance, while chromium improves its hardness properties, especially at high temperatures. The tensile strength properties of 625 Inconel alloy forging rods are obtained by the hardening of molybdenum and niobium on the nickel-chromium matrix of the alloy. Therefore, nickel alloy 625 square bar does not require precipitation hardening.