inconel 625 stub end pipe fittings

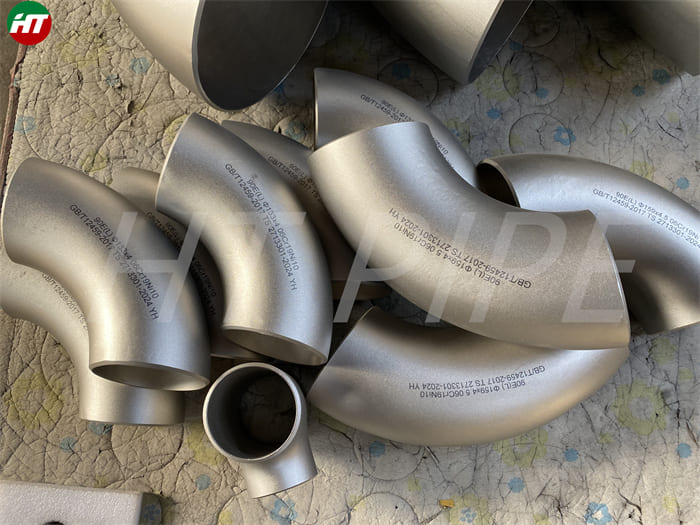

Inconel 625 Pipe Fittings are strong and are used in high corrosive applications that need stronger pipes. The material is a nickel chromium molybdenum alloy with niobium in the composition for stabilization. It can operate from cryogenic temperatures up to 1093 degrees Celsius. So the fittings are preferable for applications that require high strength, corrosion resistance and high temperature resistance. The Alloy 625 Buttweld Fittings are used with ease of welding and this is the most used type of fittings. The Inconel UNS N06625 Pipe Elbow is used to turn the pipe away by an angle, usually 45 degrees or 90 degrees. The ANSI B16.9 ASTM B366 625 Inconel Monel Tee can range from ? inches to 48 inches in nominal bore size and it branches a pipe into two.

Type Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers

Size OD: 1/2″ ~48″

Thickness: SCH5~SCHXXS

Manufacturing technique£ºpull, push

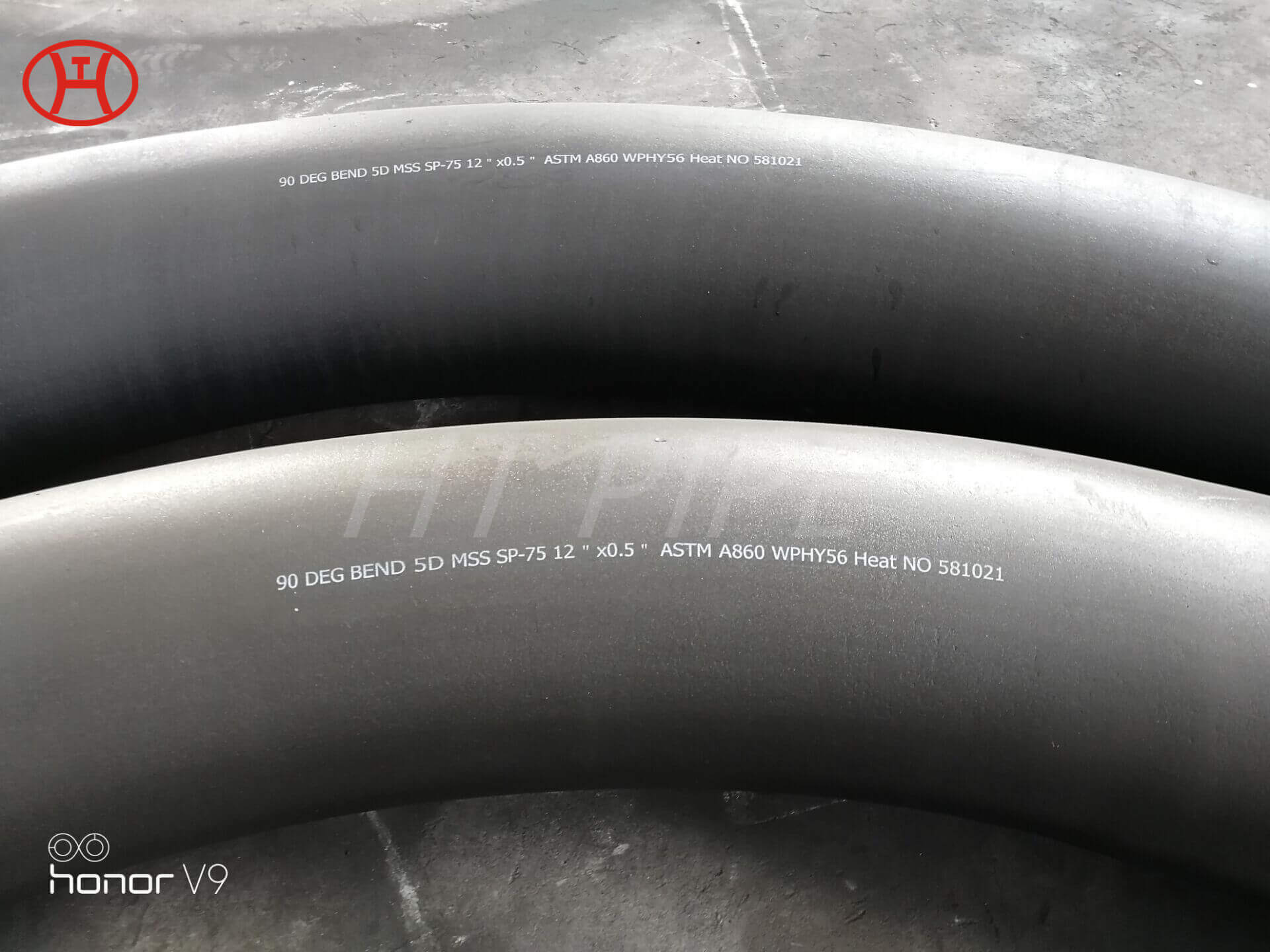

Producing Standard ASME B16.9 ASME B16.28 ASME B16.49 MSS SP-43 MSS SP-75

Material Nickel Alloy ASTM/ASME SB 366 Alloy 200/UNS N02200, Alloy 800HT/Incoloy 800HT/UNS N08811, Alloy 400/Monel 400/UNS N04400, F904L/UNS N08904, Alloy 800/Incoloy 800/UNS N08800, Alloy C-2000/UNS N06200, Alloy 925/Incoloy 925/UNS N09925, Alloy C-22/UNS N06022, Alloy 201/UNS N02201, Alloy C-276/Hastelloy C-276/UNS N10276, Alloy 625/UNS N06625, Nimonic 80A/Nickel Alloy 80A/UNS N07080, Alloy K-500/Monel K-500, Alloy 20/UNS N08020, Alloy 800H/Incoloy 800H/UNS N08810,Alloy 600/Inconel 600/UNS N06600, Alloy 31/UNS N08031,Alloy 825/Incoloy 825/UNS N08825,Alloy 20/N08020