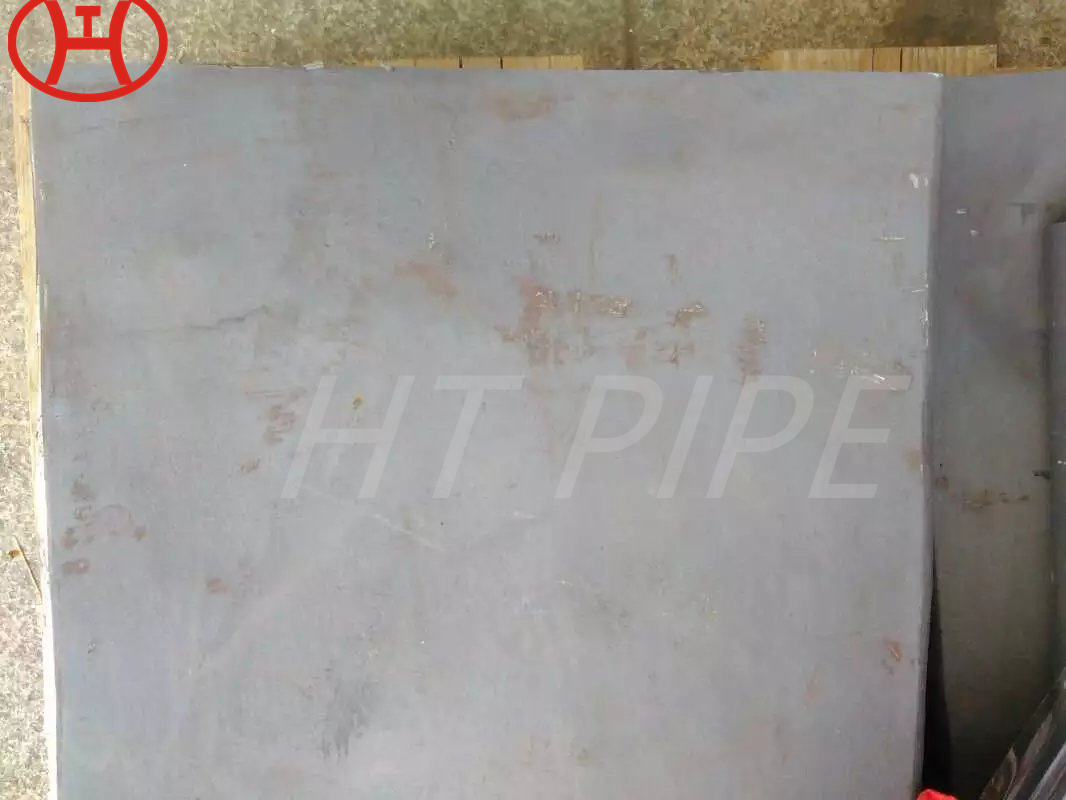

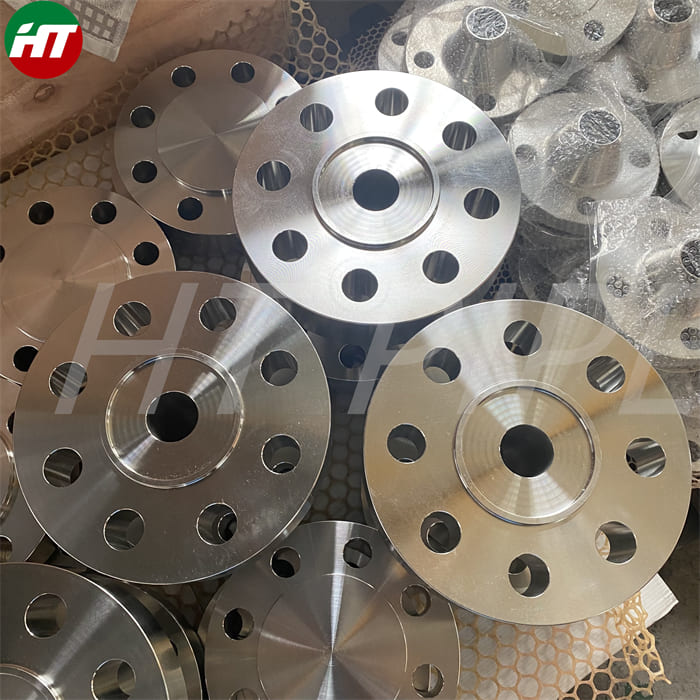

Inconel 718 forged plate 2.4668 forged material

Inconel 718 is a nickel-based precipitation hardening alloy designed for very high yield strength, tensile strength and creep rupture properties at temperatures up to 1300ºF (705ºC). This alloy has excellent solderability.

Inconel 718 is a heat-resistant alloy, a high-strength, corrosion-resistant nickel-chromium alloy that can be used in temperatures from -423°F to 1300°F, originally developed for the aerospace industry and is still considered It is the material component of choice for most aircraft engines. Its excellent strength and corrosion resistance have been recognized by the petroleum industry and are now widely used in this field.

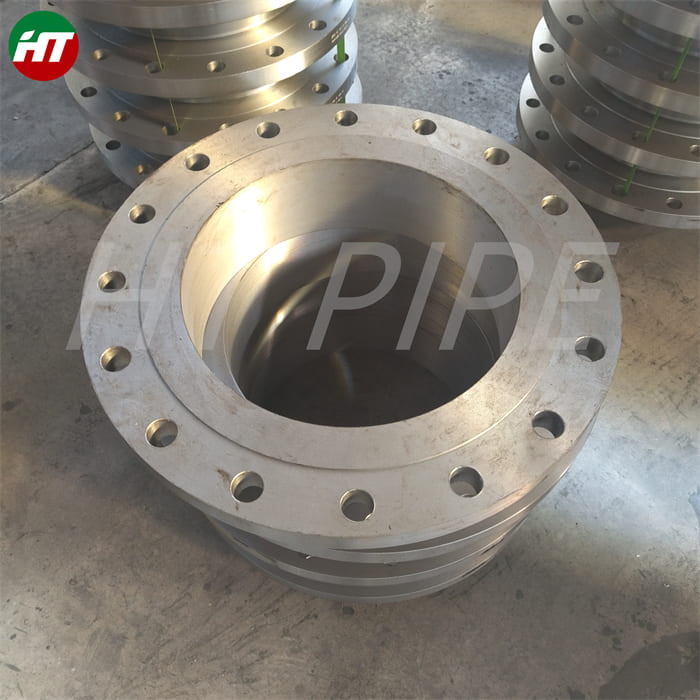

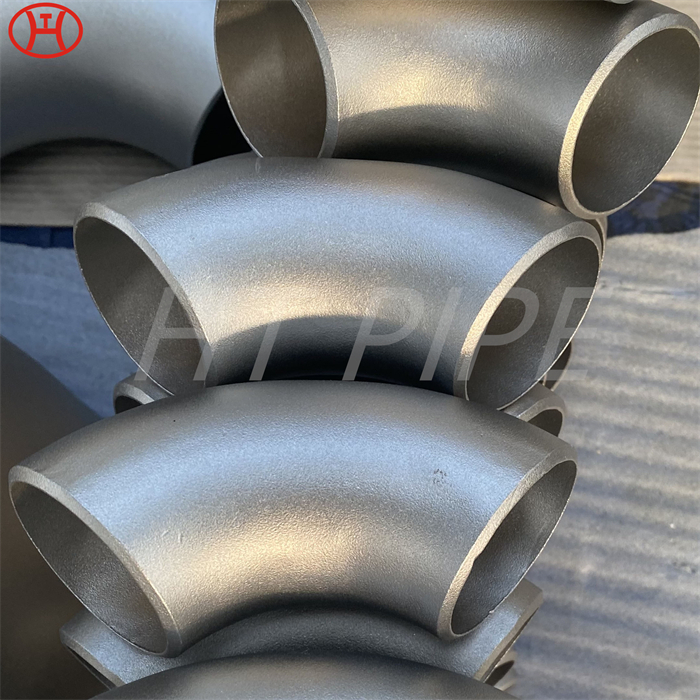

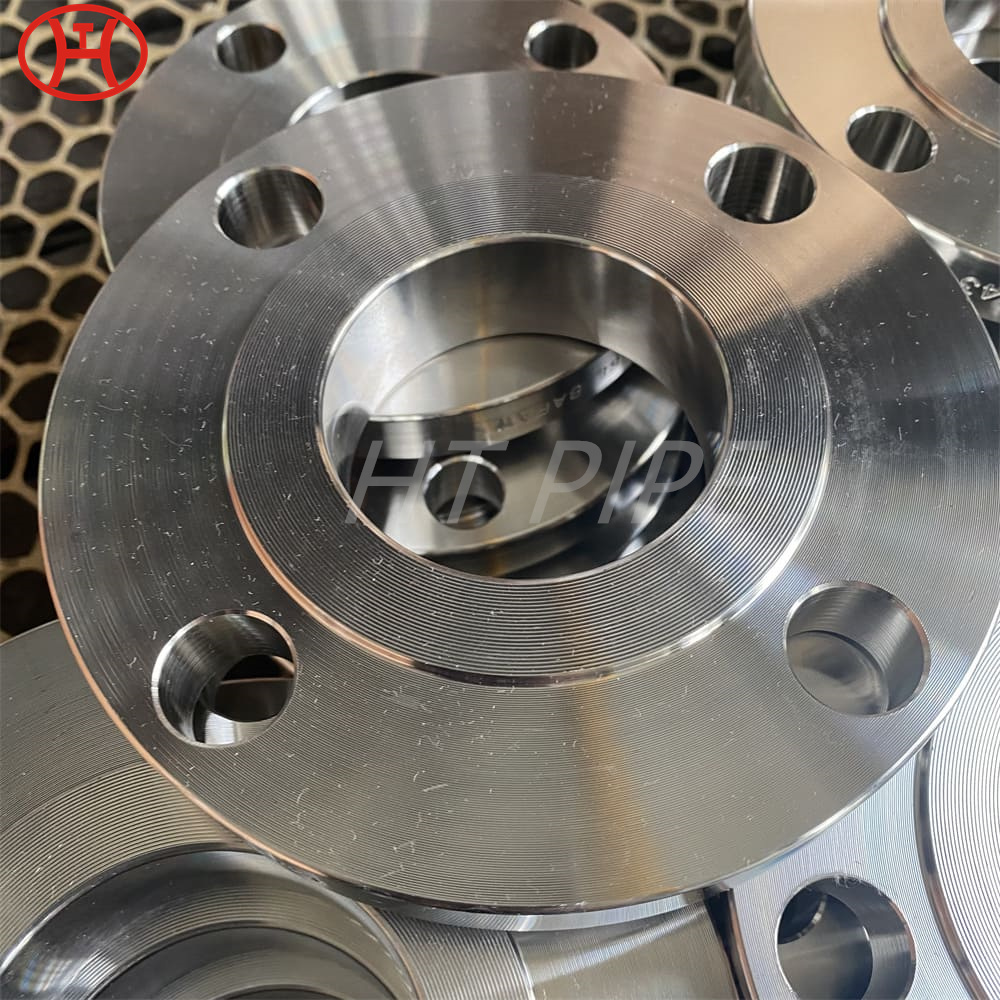

Workpiece and tooling for nickel 718 forgings should remain rigid and tool overhang should be minimized. Nickel Alloy 718 forgings perform well over a range of temperatures while maintaining creep resistance, corrosion resistance, tensile strength and yield strength to prevent stress cracking under common operating conditions.

The alloy is used in jet engines and high-speed airframe components such as wheels, buckets and spacers, as well as high-temperature bolts and fasteners. Inconel 718 is also used in the oil and gas drilling and production industries due to its high strength and resistance to chloride, stress corrosion and sulfide stress cracking. In these industries, the alloy has been used in valves, pump shafts and wellhead components.