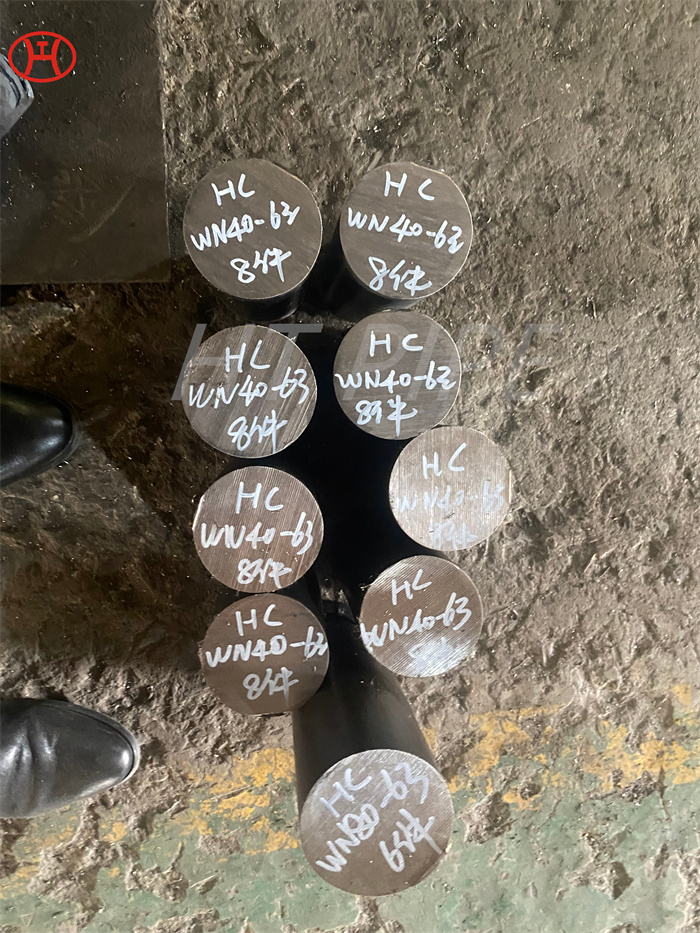

Inconel 718 round bar price N07718 solid round steel bar

The ASTM B166 specification is the standard for Alloy 718 ASTM B166 hot rolled bar.

According to this specific standard, Inconel 718 round bar needs to be delivered uniformly in a quality and smooth condition, while being commercially straight or flat and free from detrimental defects. ASTM B166 718 Mechanical properties of cold-worked bars, such as tensile strength, yield strength, elongation, and hardness of the material, are determined by conducting tests such as tensile and hardness testing.

Meanwhile, Inconel 718 round bar is a chromium-nickel alloy bar that also contains significant amounts of molybdenum, titanium, iron, aluminum and niobium. They are precipitation hardened rods with excellent creep stress rupture strength and durability. These bars are permanently enhanced for excellent low temperature performance and formability. The bar has excellent oxidation and corrosion resistance at high temperatures.

In addition, Nickel Alloy 718 maintains high strength and good ductility and oxidation resistance at high temperatures; on the contrary, it has excellent low temperature properties. An example of these combined properties used in an application can be seen in the aerospace industry. Nickel alloy 718 provides the important strength required by aircraft to withstand the heat of the afterburner and freezing temperatures at high altitudes.