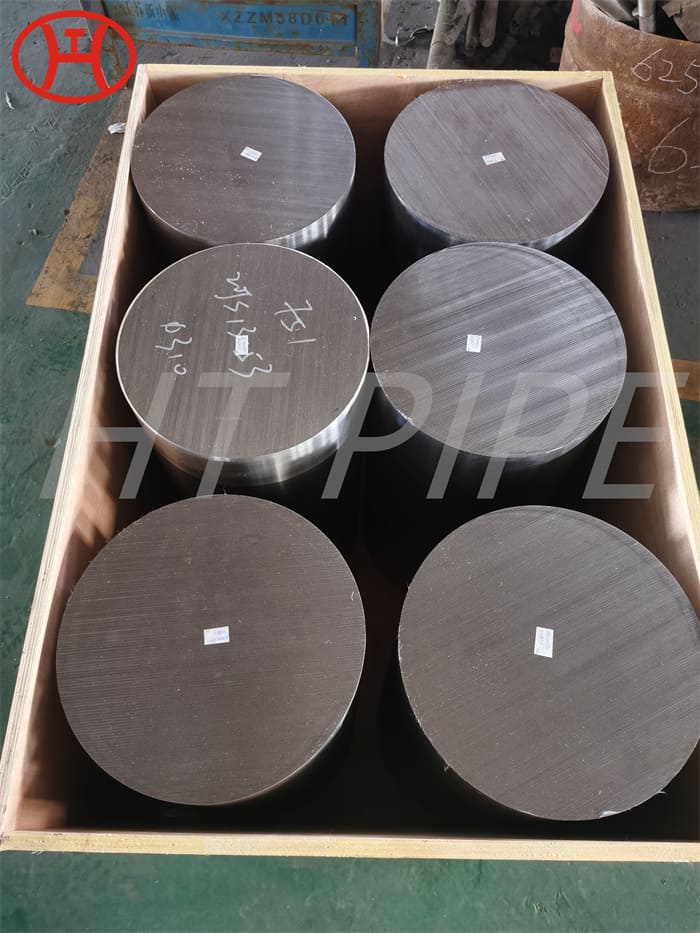

Inconel 718 steel round bars N07718 angle steel bars

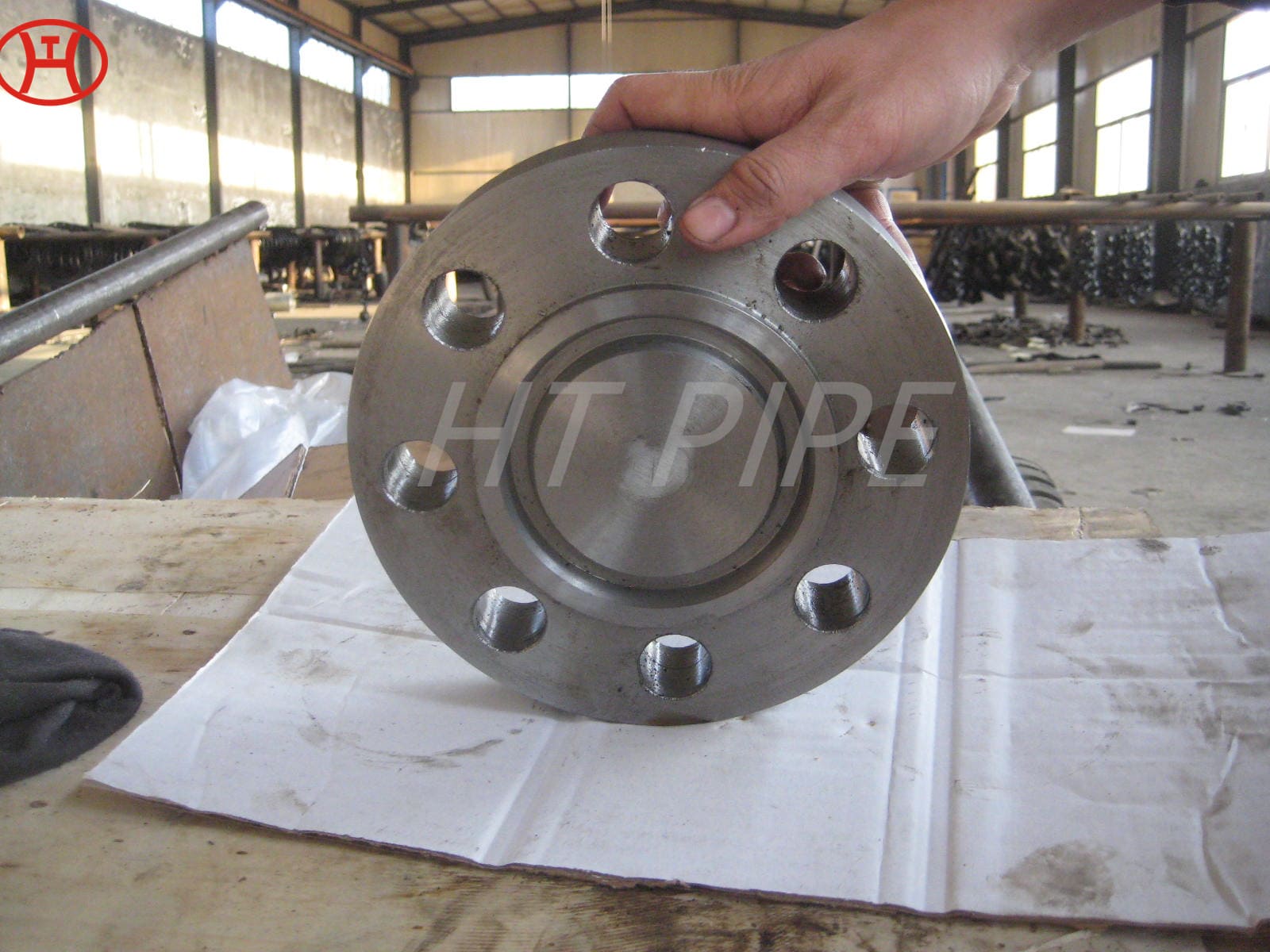

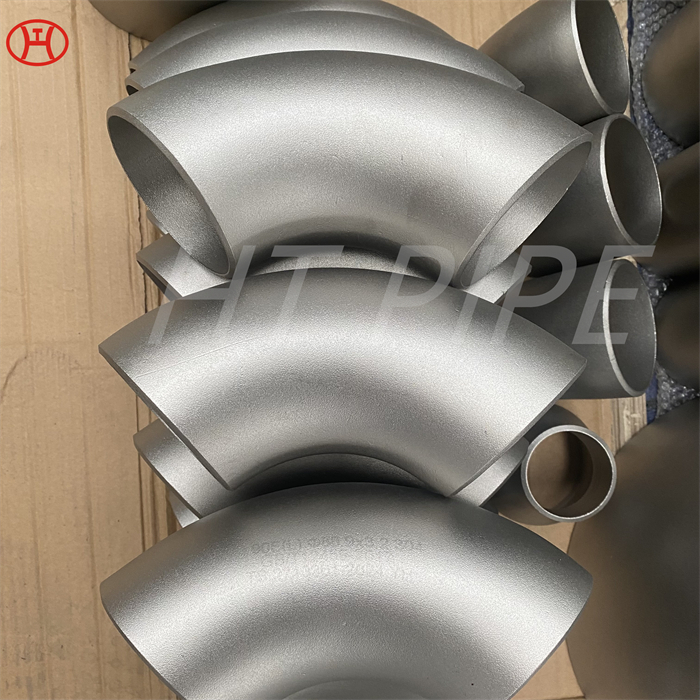

Inconel 718 is a chromium and nickel based alloy with additional amounts of titanium, niobium, iron, molybdenum and aluminum. This alloy has high mechanical strength and durability to withstand extreme environmental conditions. Inconel 718 round bar has excellent resistance and solderability. These bars have excellent overall corrosion resistance in high temperature and high pressure applications.

A key feature of Inconel 718 is its processing versatility. It can be fabricated over a wide range of temperatures, forging reductions and strain rates to produce microstructures and associated properties tailored to specific requirements. Inconel N07718 round bar is a nickel-based superalloy. It is ideal for applications requiring high strength in temperatures ranging from cryogenics to 1400°F. Inconel 718 also has excellent tensile and impact strength. Alloy 718 Round Bar (W.Nr. 2.4668/UNS N07718) is a corrosion-resistant nickel-chromium material for use in temperatures from -423° to 1300°F.

Inco 718 has excellent solderability and good resistance to strain age cracking. The excellent solderability characteristics are related to the slow precipitation characteristics of the primary strengthened gamma double bottom phase. Typical aerospace applications include compressor and turbine disks, blades, gaskets and bolts for jet engines, and liquid rocket components involving low temperatures. Standard specifications include AMS 5596, AMS 5662, etc.