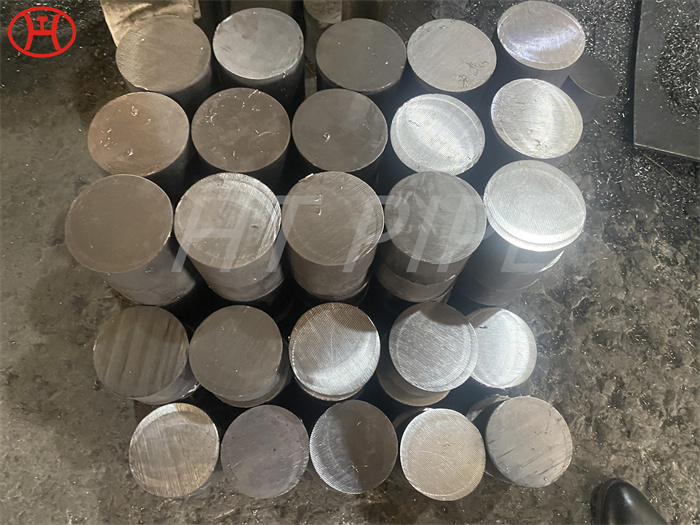

Inconel 718 steel round bars WERKSTOFF NR. 2.4668 mild alloy 718 steel round bar

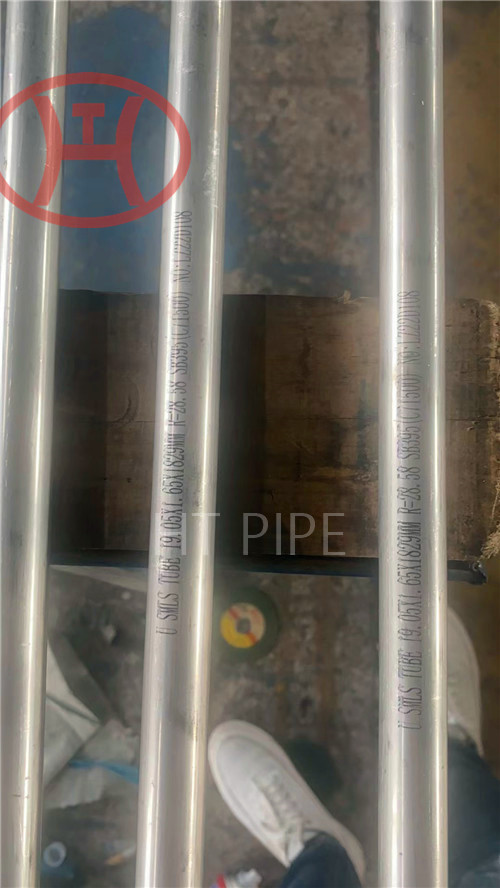

Inconel 718 can be described as a nickel-chromium alloy containing molybdenum, niobium, iron and very small amounts of titanium and aluminum. Inconel 718 round bars are strong and they also show remarkable yields.

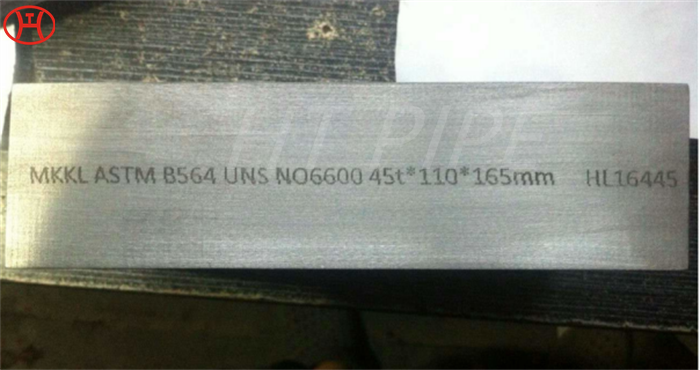

The excellent toughness and strength of Inconel 625 round bar (Alloy 718) is a direct result of the inclusion of niobium, which solidifies the matrix of the alloy through molybdenum. Also known as UNS N07718, these round bars and round bars can be further customized in size and thickness according to the specific prerequisites given by our esteemed customers. Inconel 718 round bars are also known for their creep rupture properties up to 704 degrees Celsius and are also highly ductile. Additional properties of Inconel 718 electrodes include good weldability and formability. It also shows a higher low temperature allowance than other nickel-based superalloys.

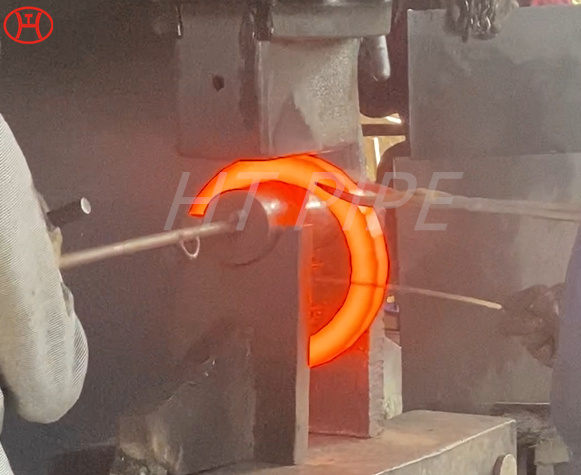

Additionally, Alloy 718 is an age-hardenable NiCrFeMo alloy with a nickel content of 50% to 55%. Alloy 718 was originally developed for the aerospace industry and is still considered the material of choice for most aircraft engine components today. Its excellent strength and corrosion resistance have been recognized by the petroleum industry and are now widely used in this field. 718 Inconel round bars can also be hot worked in a furnace up to 1121 degrees Celsius. Cold and hot working of 718 Inconel round bars in the temperature range of 927-1010 degrees Celsius will increase the forging strength, taking into account the service temperature within 593 degrees Celsius.