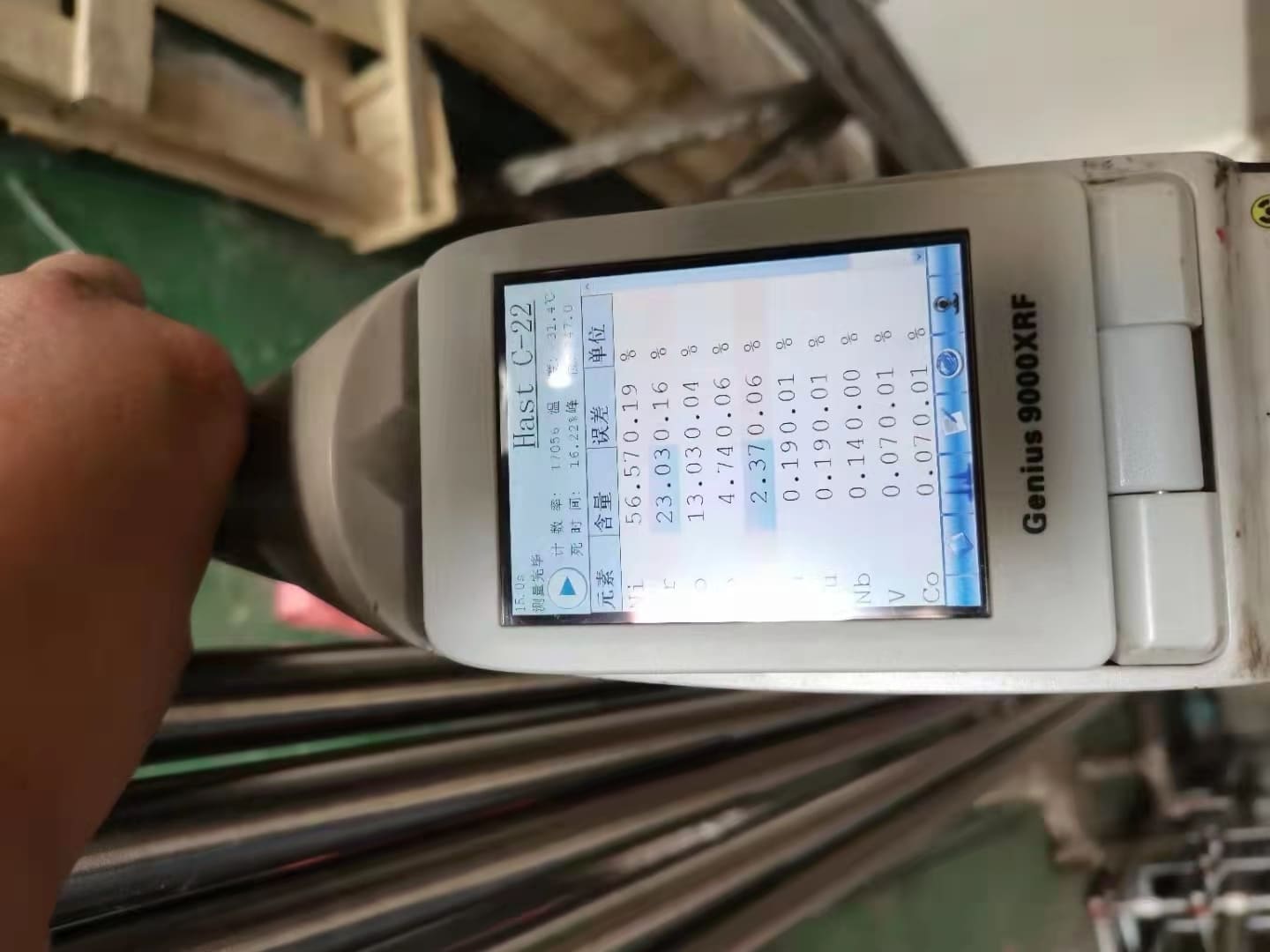

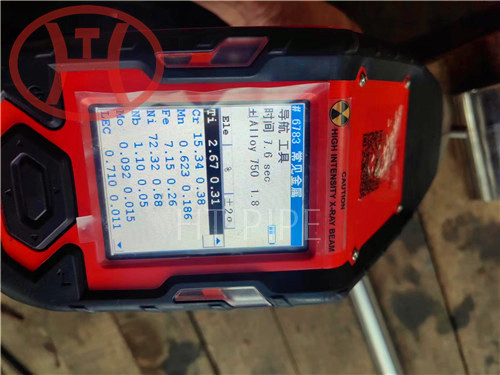

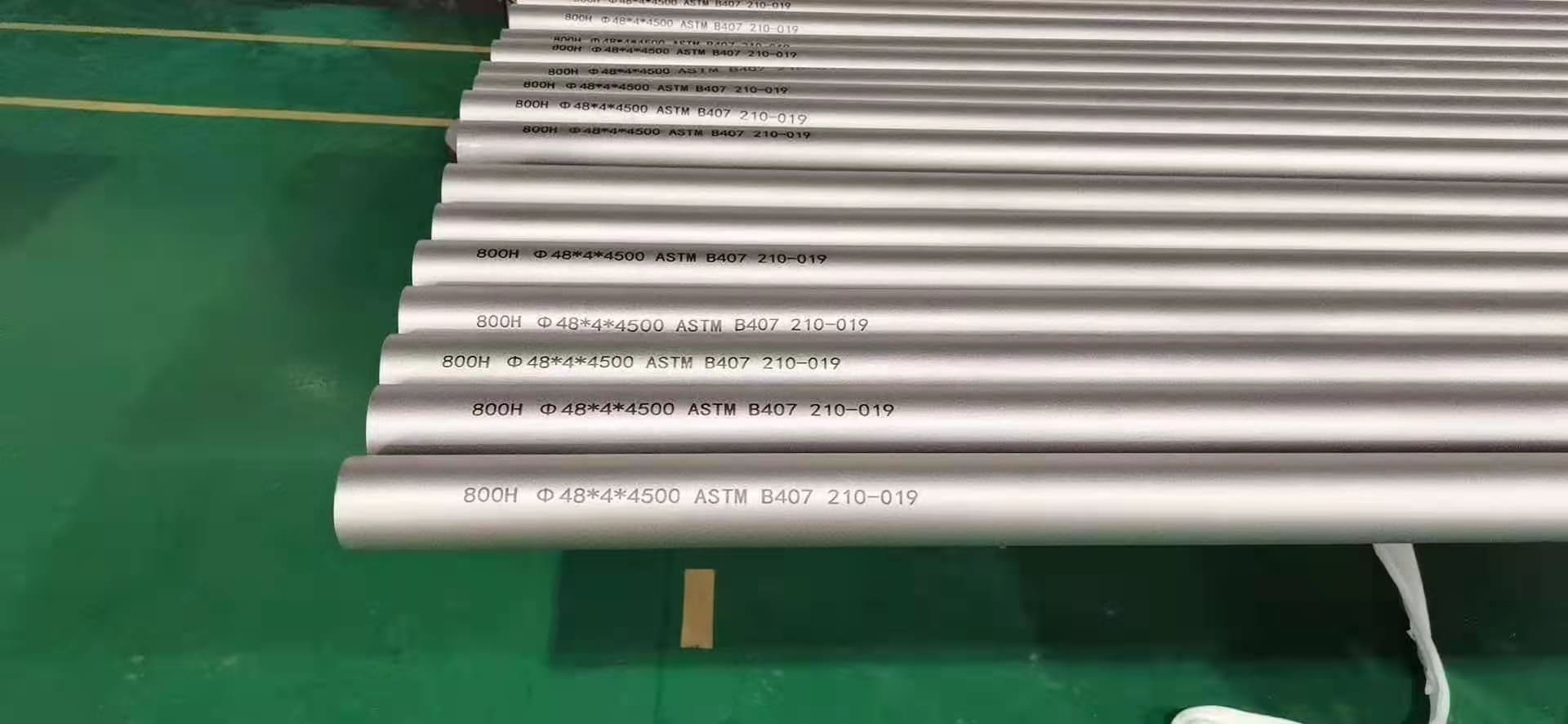

inconel 718 tube N07718 2.4468

Alloy 718 was initially developed for the aerospace industry but its excellent strength and corrosion resistance were recognised by the oil industry and it is now widely used in this field as well.

Alloy 718 is a nickel-chromium alloy which can be heat-treated to give high strength, good corrosion resistance, ease of formability and which can be welded with good resistance to strain age cracking. The alloy can be used at temperatures up to 700oC.

Inconel WERKSTOFF NR.2.4668 tubing is a precipitation hardened nickel based alloy. Inconel 718 tubing is designed for applications requiring very high yield strength, high tensile strength, and good creep rupture performance. Alloy 718 Nickel Tube is an age-hardenable nickel-chromium-iron alloy that also contains significant amounts of niobium, molybdenum, titanium and aluminum. It combines good corrosion resistance with extremely high strength. Alloy 718 condenser and heat exchanger tubes are produced to ASTM B163 specifications. In several industries, heat exchanger applications include cooling and heating of large manufacturing systems.