Low alloy steel elbow ASTM A234 WP91 elbow

A butt weld pipe fitting is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

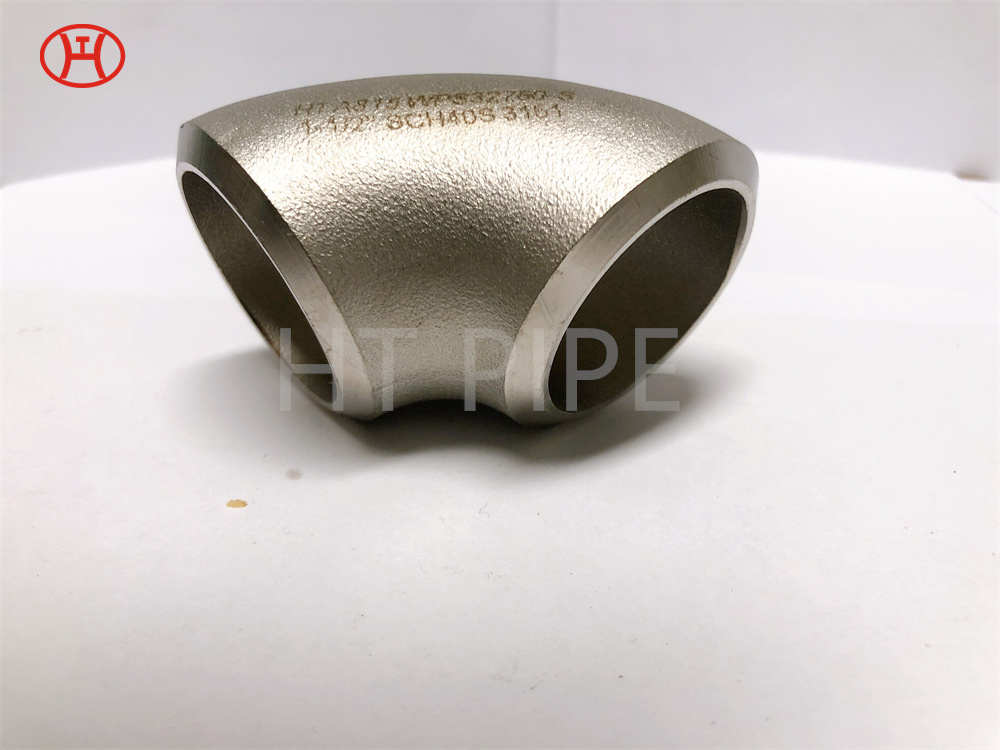

⇒Steel pipe elbow⇐ is an important parts in plumbing pipeline systems and used to change the fluid directions. It ranges in different types as per body material there are stainless steel elbow, carbon steel elbow, and alloy steel; As per fluid directions there are 45 degree , 90 degree elbow and 180 degree; As per elbow length and radius there are short radius elbow (SR elbow) and long radius elbow (LR elbow); As per connections types there are butt weld elbow, socket weld elbow and threaded steel piping elbow.

In simple terms, steel pipe elbow is a type of pipe fitting connected between two pipes. The main purpose is to change the course of direction. As we know, steel elbow can be classified into different degrees, normally is 45 degree steel pipe elbow, 90 degree steel pipe elbow and 180 degree steel pipe elbow. Other degree like 60¡ã or 120¡ã also used in pipeline systems in case special requirements.

| ASTM A234 WP91 Chemical Composition | |||||||

| Grade | C | Mn | Si | S | P | Cr | Mo |

| ASTM A234 WP91 Pipe Fittings | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 0.44-0.65 |