low-alloy steel pipe

The material can be heat treated to anneal and normalize in air, or quench and temper in polymer or oil. Alloy 4130 has a lower carbon content of 0.28% – 0.33% and slightly higher amounts of other elements. And the material is easy to process. 4140 low alloy steel has a range of 2. 375″ to 12.750″ OD with wall thicknesses ranging from 0.375″ to 1.5″. Alloy 4145 has a slightly higher carbon content than 4140 and 4130 types of pipes.

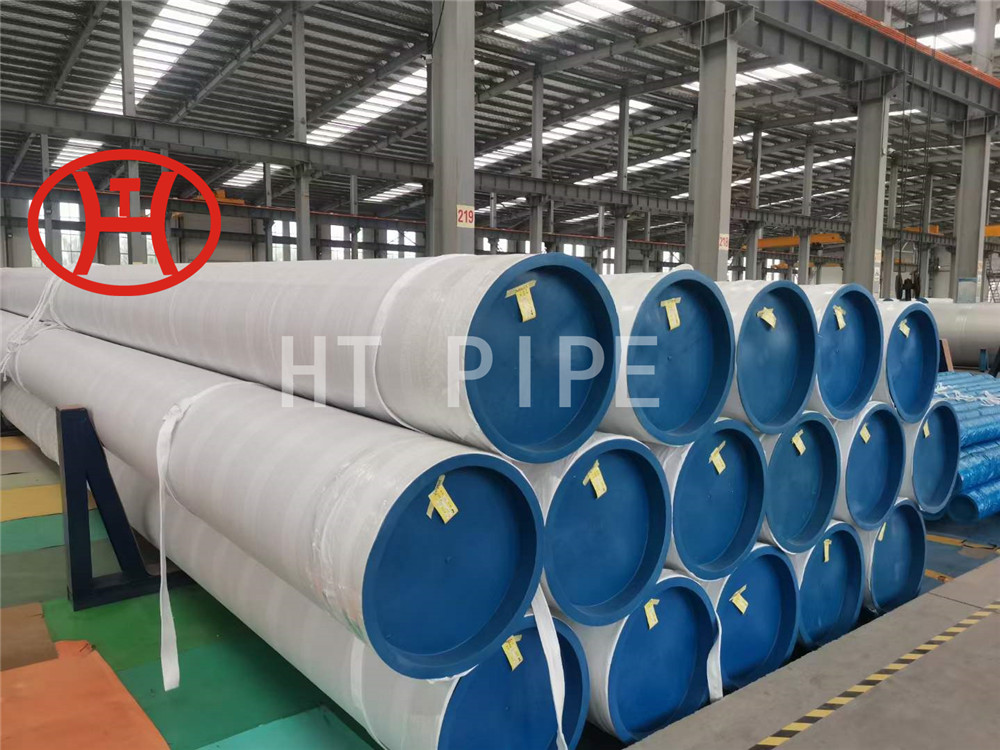

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

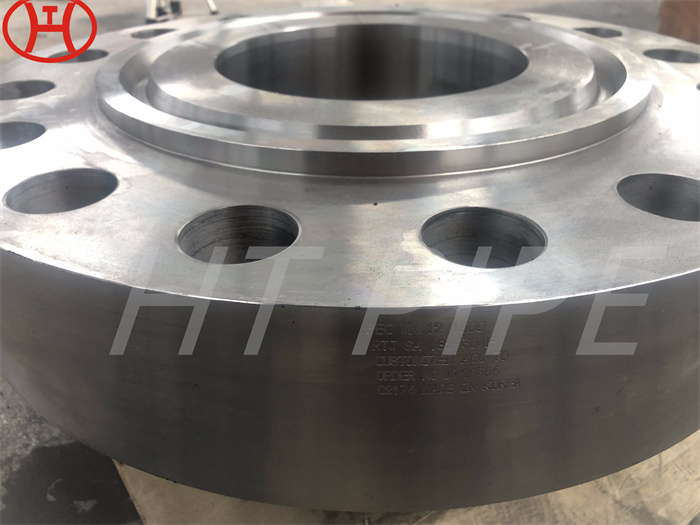

Producing Standard ASME B36.10 ASME B36.19

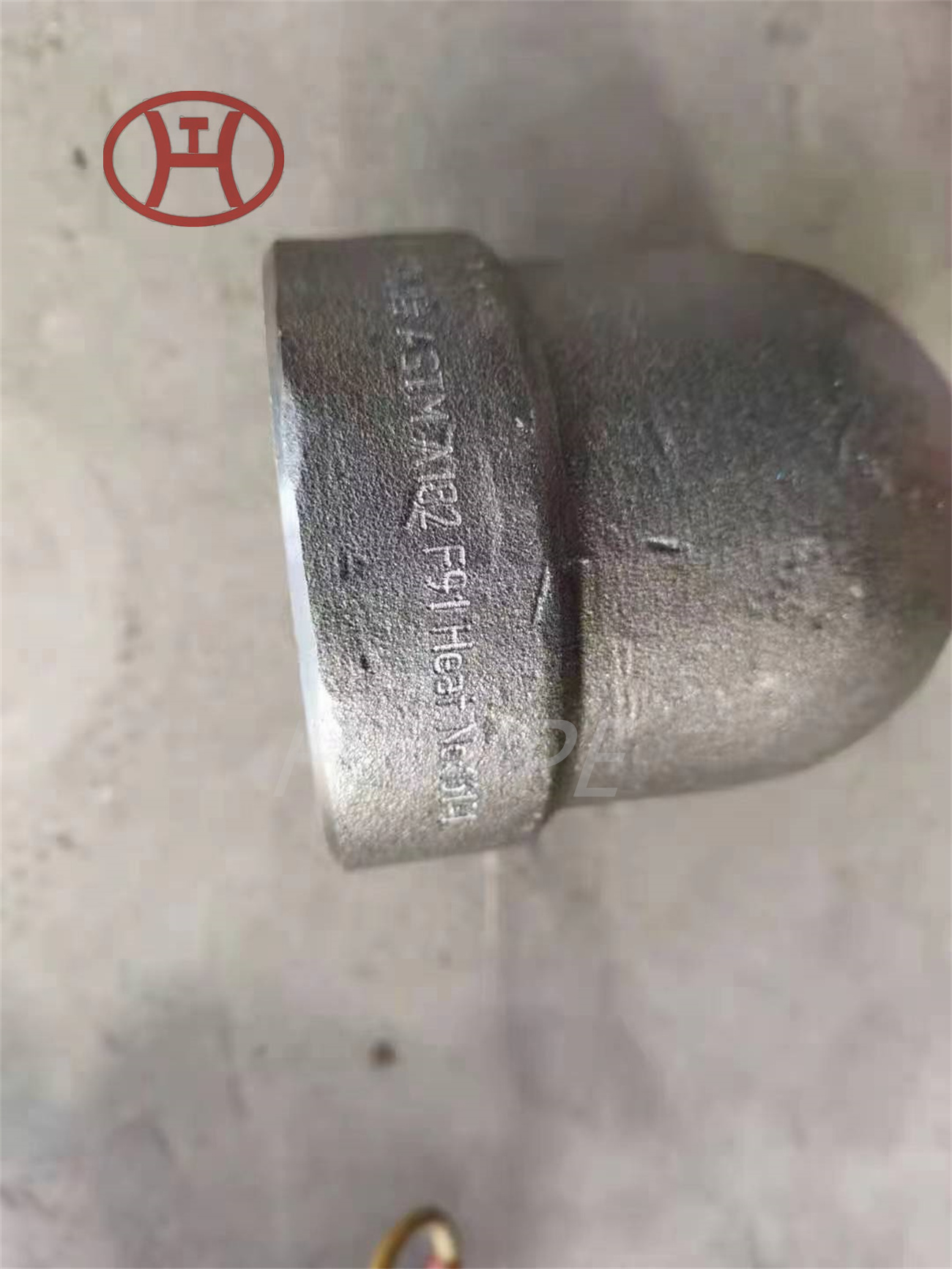

Material Alloy Steel ASTM A333 Grade 3, Grade 6,Grade 8,Grade 9

ASTM A335 P5,P9,P11,P12,P22,P91,P139

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Alloy Steel ASTM A333 Grade 3, Grade 6,Grade 8,Grade 9

ASTM A335 P5,P9,P11,P12,P22,P91,P139