Low alloy steel tee ASTM A234 WP91 tee

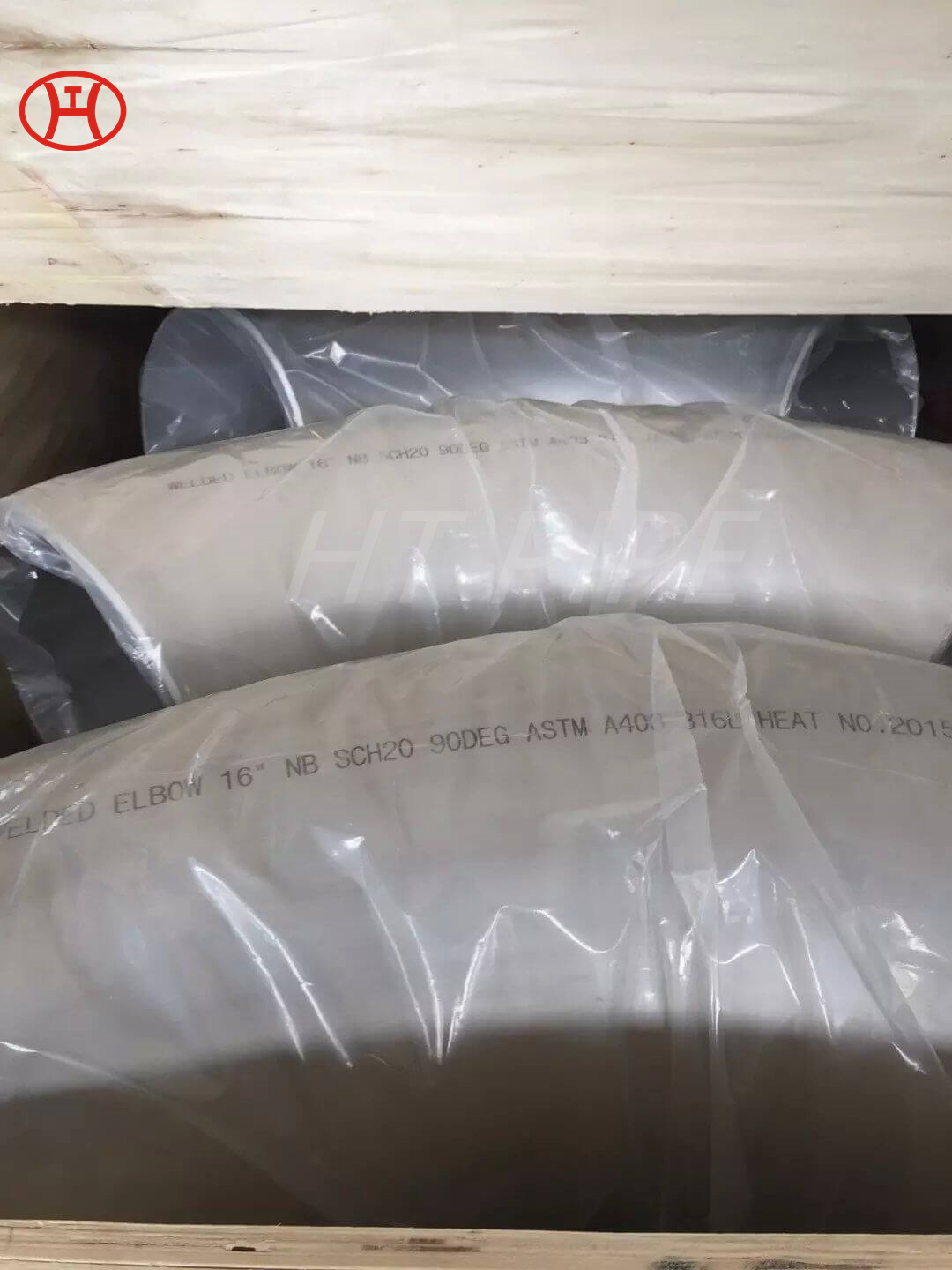

A butt weld pipe fitting is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

⇒Steel tee⇐ is a T shaped pipe fittings that has three branches, normally has two forms with?Equal Tee?and?Reducing Tee?(Tee reducer), both are used to divide (combine) the pipelines to adjust the flow rate and change the direction.

Steel Equal Tee pipe fittings: The three branches of tee have same diameters.

Steel Reducing Tee / Reducer tee pipe fittings: The branch diameter is smaller than the main line diameter. Tee reducer is usually described as NPS diameters in 4 x 4 x 3, 4 is the main line pipe diameter, and 3 is the reducing branch.

Reducing tee is used more than equal tee since it has more functions and available for more environments.

| A234 WP91 Mechanical Properties | ||||||

| Gr | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % | |||

| ASTM A234 WP91 Pipe Fittings | 415 – 585 | ≥205 | ≥20 | |||