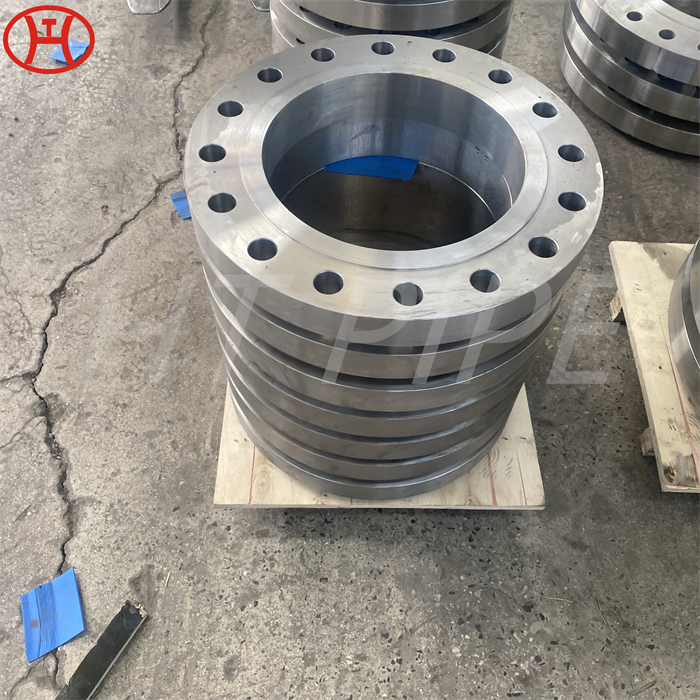

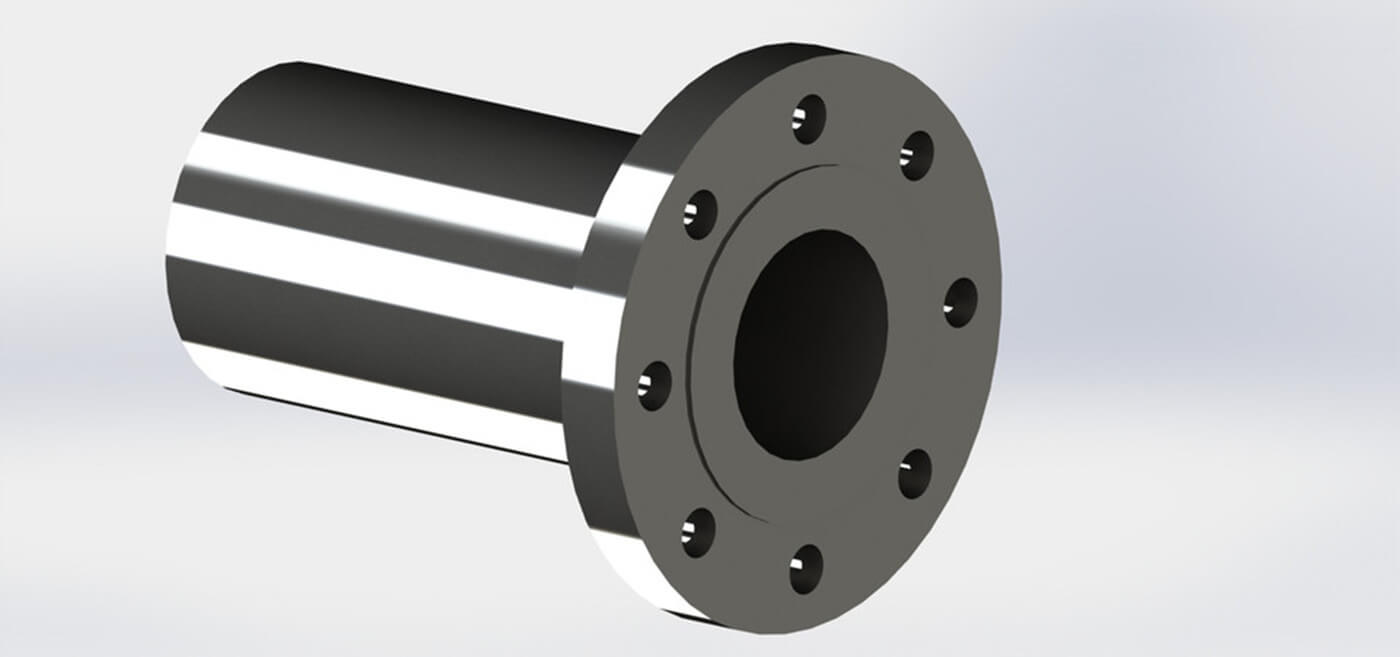

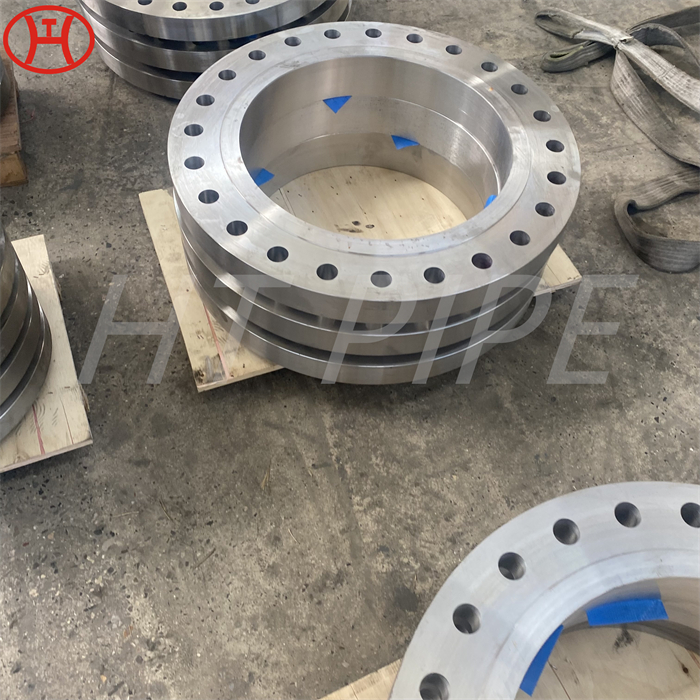

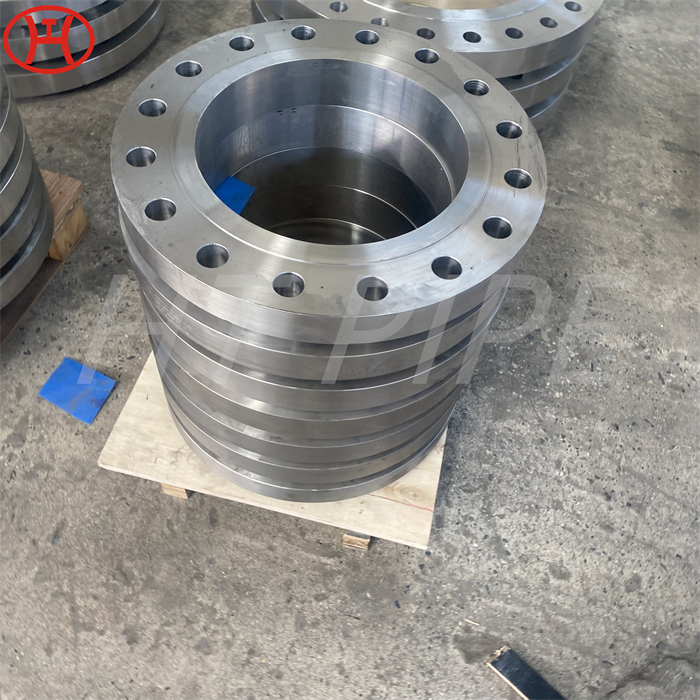

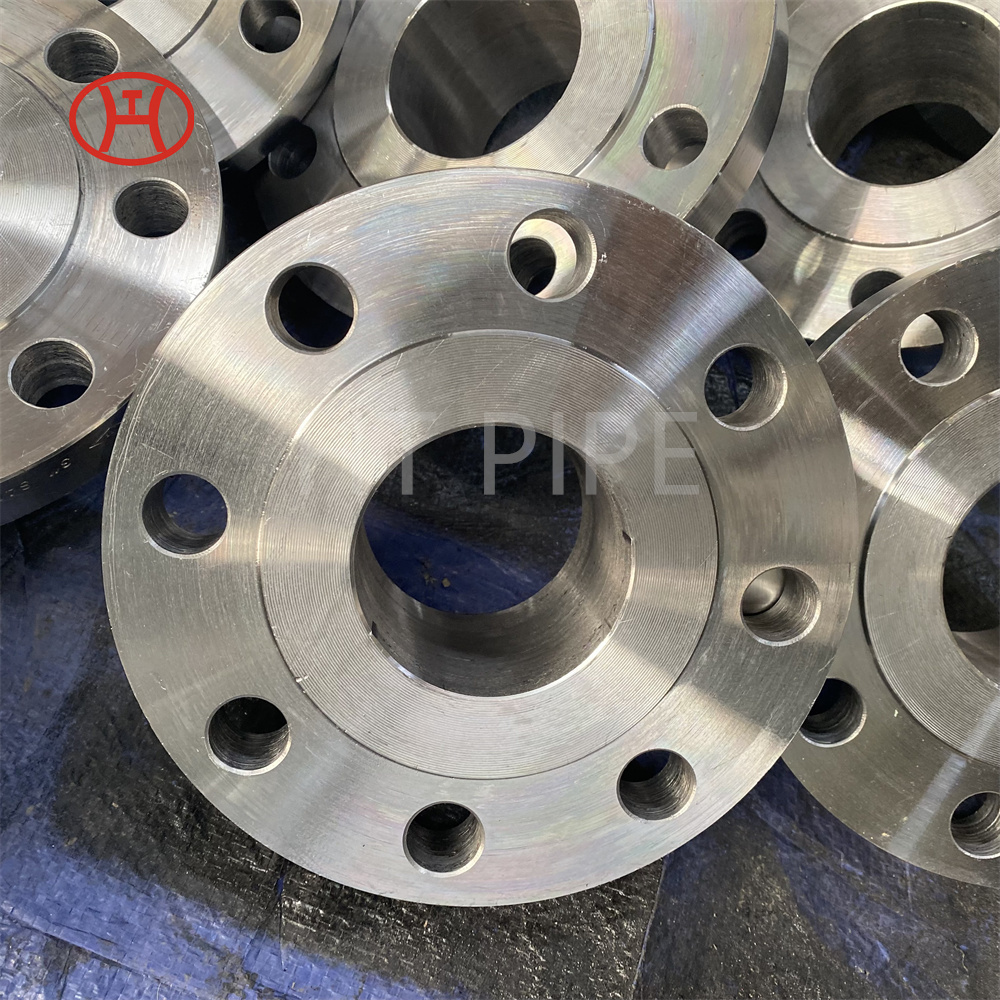

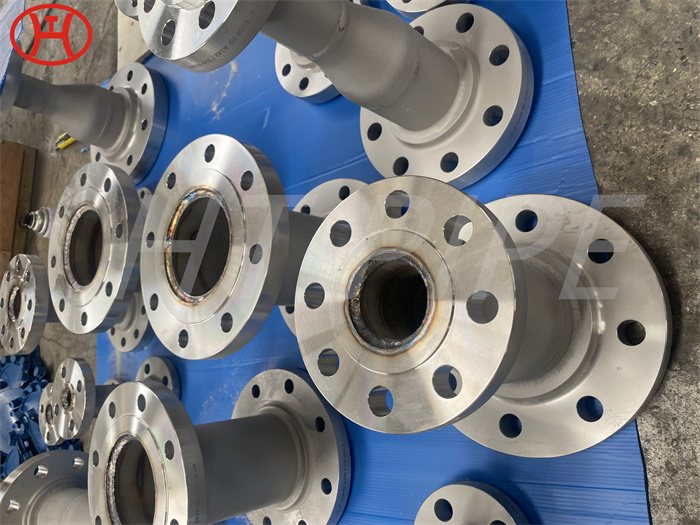

Monel K500 2.4375 N05500 pipes with tees and flanges

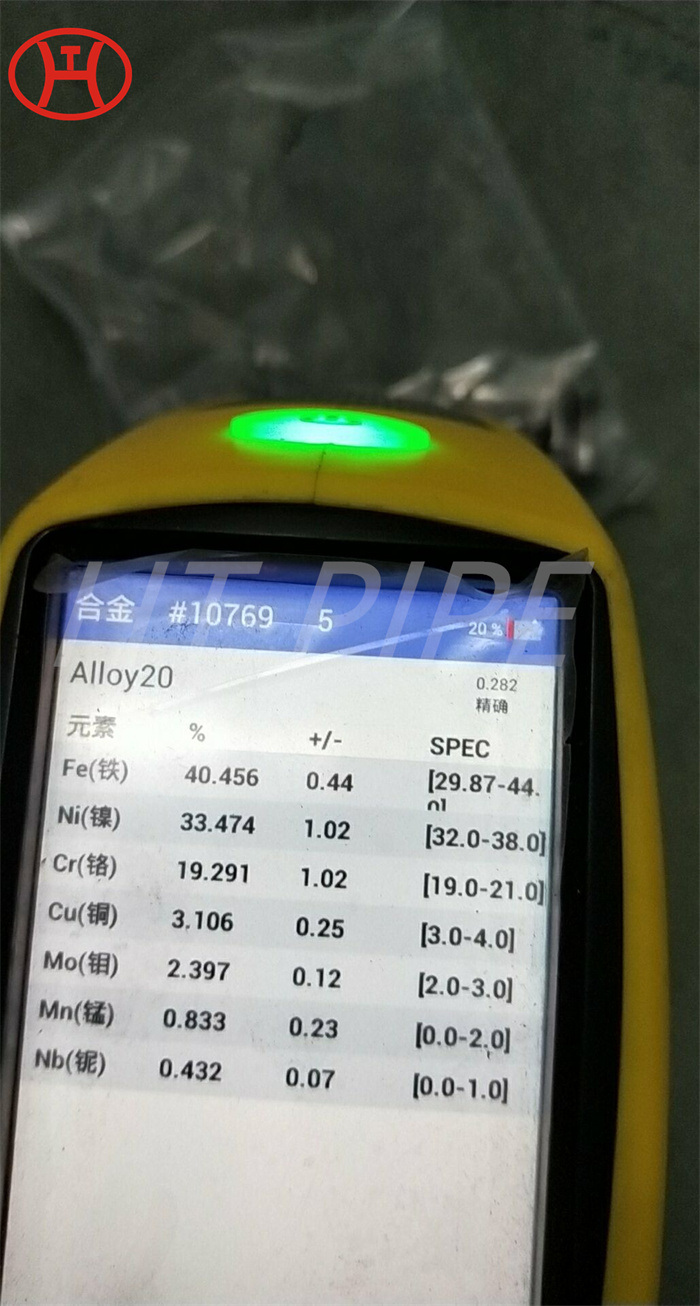

Alloy K500 is refined by Electroslag Refining (ESR), ensuring the cleanest and highest quality material. This increased alloy purity limits the potential for hard non-metallic inclusions that can increase machining difficulty, machining time and ultimately lead to part failure. It also has low permeability and is non-magnetic at temperatures as low as -150¡ãF (-101¡ãC).

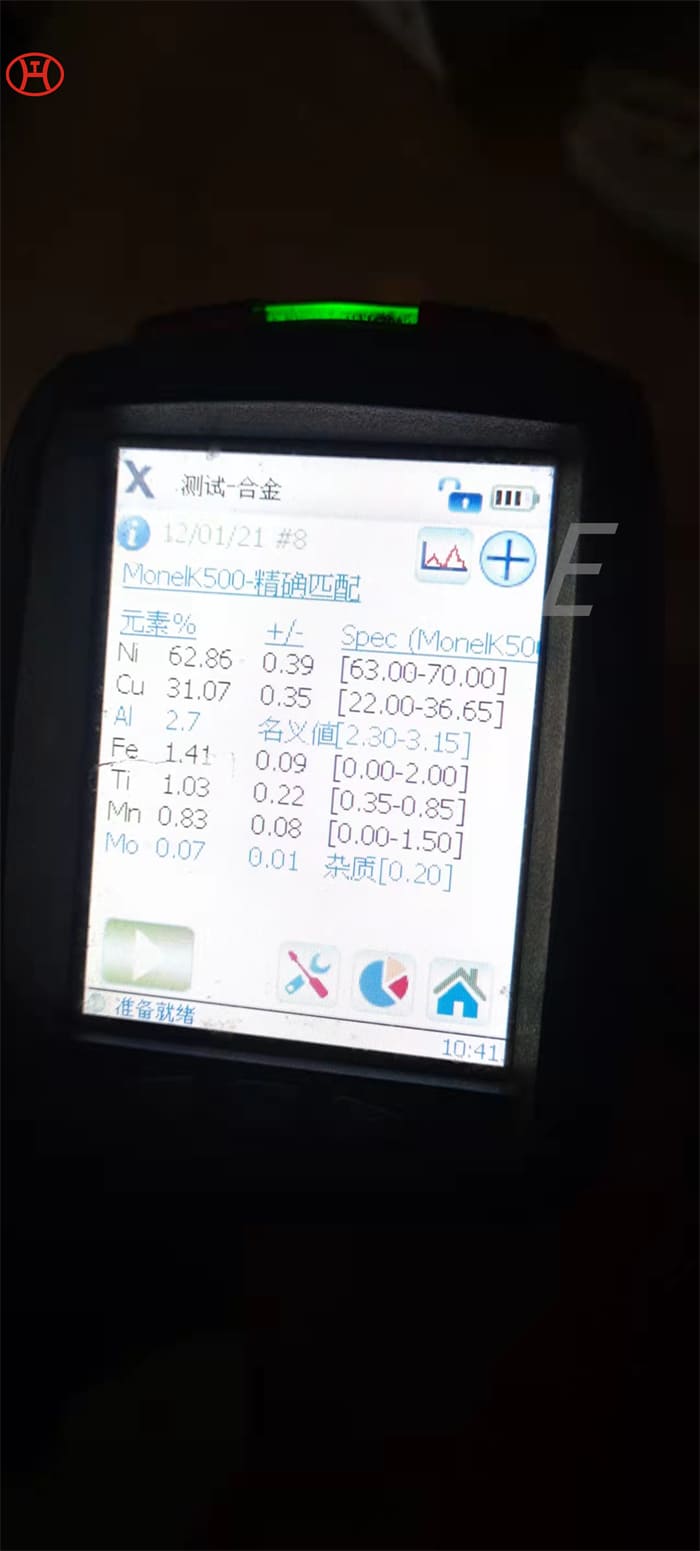

Monel K-500 combines the excellent corrosion resistance of Monel 400 with the added benefits of higher strength and hardness. Performance can be improved by adding aluminum and titanium to the nickel-copper matrix and by heating under controlled conditions to precipitate submicroscopic particles of Ni3 (Ti, Al) throughout the matrix. The heat treatment used to achieve precipitation is often referred to as age hardening or aging.

The corrosion resistance of Alloy K-500 is essentially the same as that of Alloy 400, except that in the age hardened condition, Nickel Alloy K-500 has a greater tendency to stress corrosion cracking in certain environments. Monel K-500 has been found to be resistant to sour gas environments. The combination of extremely low corrosion rates and high strength in high-velocity seawater makes K-500 alloy particularly suitable for centrifugal pump shafts in marine service. In stagnant or slow-moving seawater, scaling may occur followed by pitting, but this pitting slows down after a fairly rapid initial attack.