Monel K500 Flanges retain this strength in corrosive conditions

The corrosion resistance of Monel K500 Weld Neck Flanges is substantially equivalent to that of alloy 400 Weld Neck Flanges except that, when in the age ¨C hardened condition, it has a greater tendency toward stress ¨C corrosion cracking in some environments.

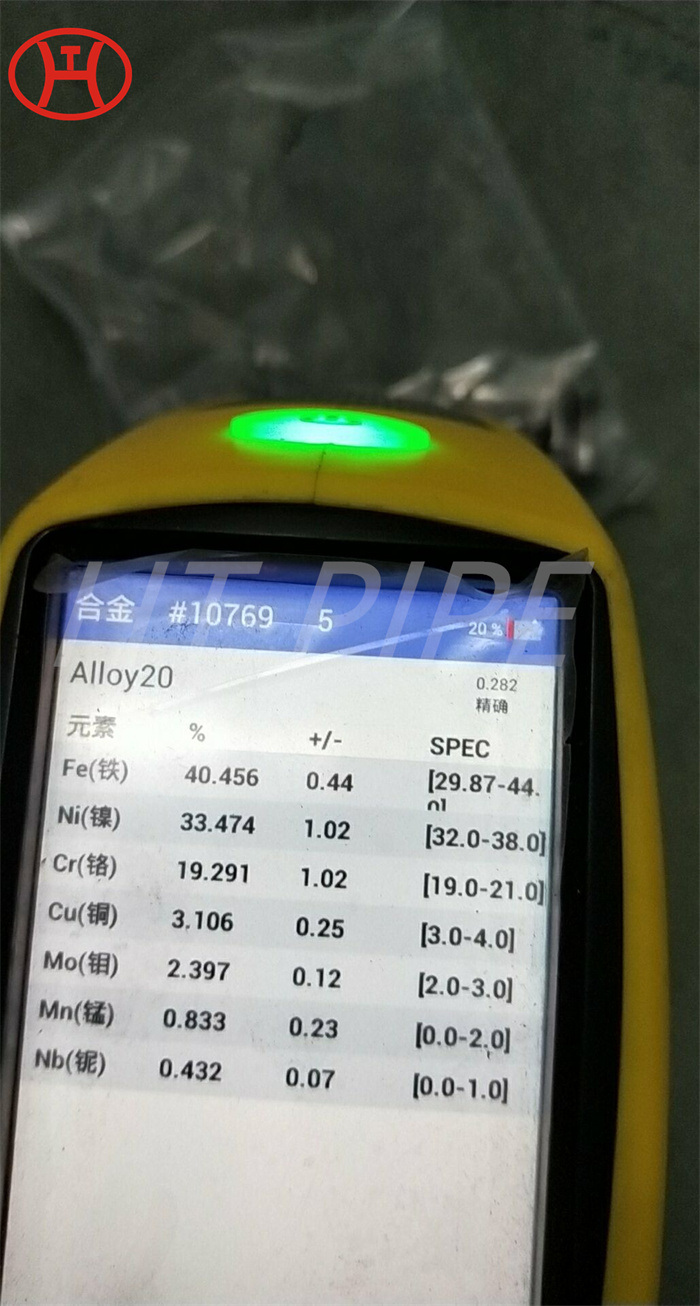

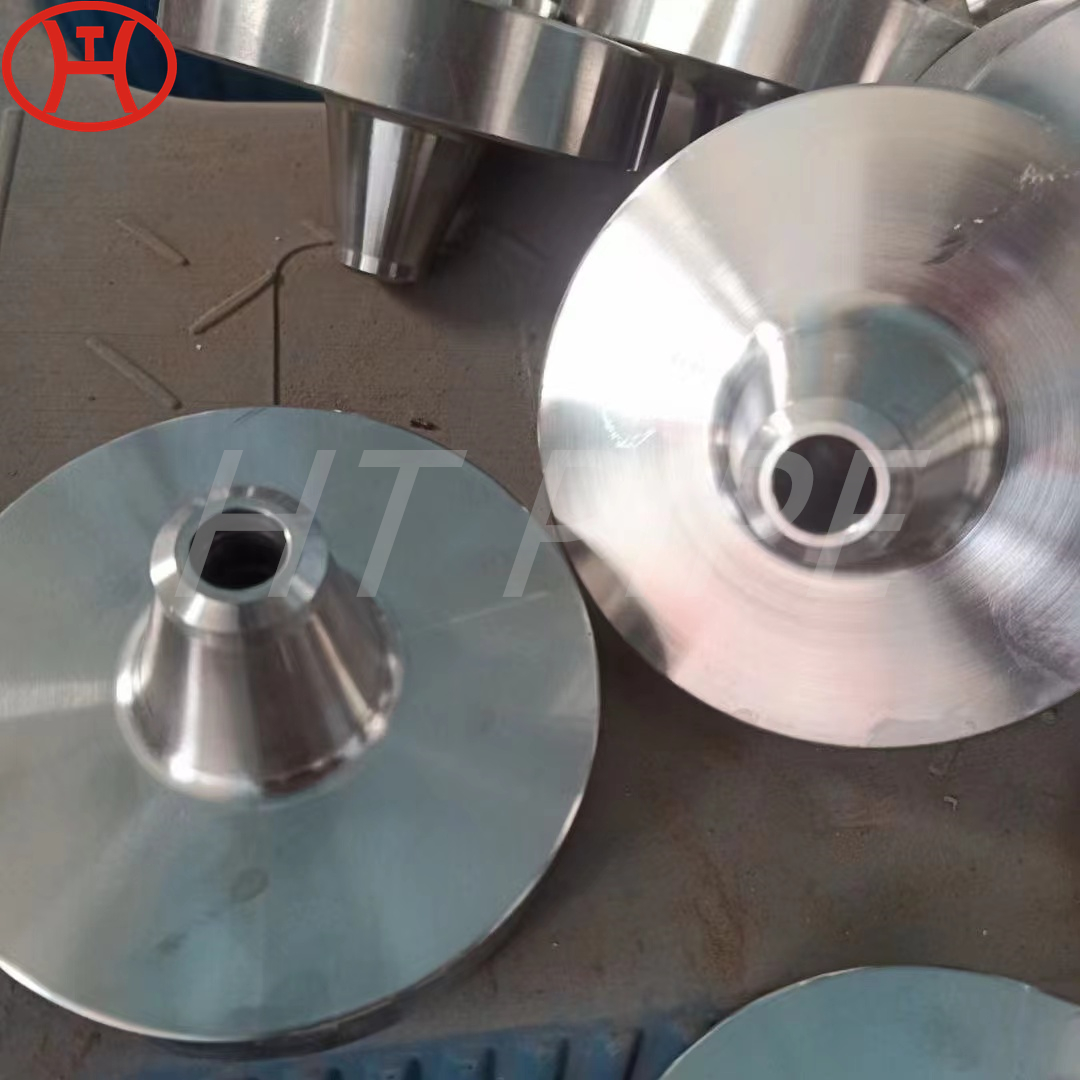

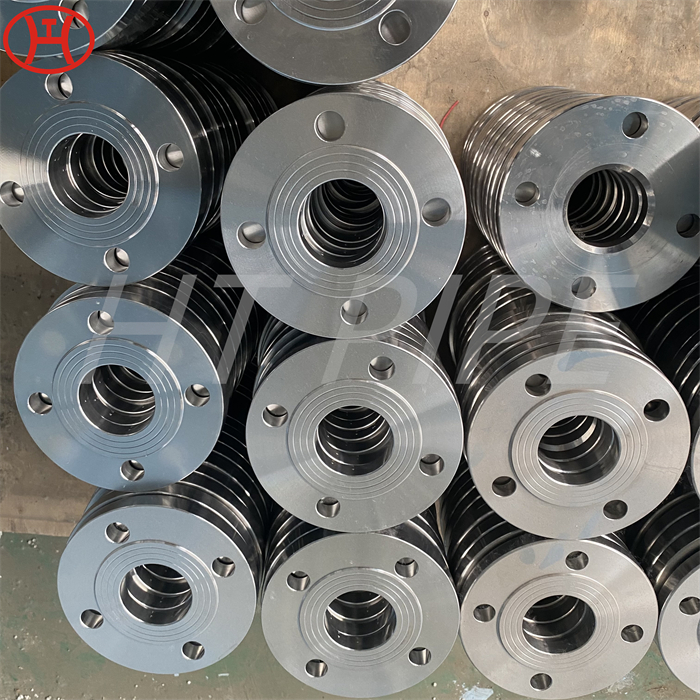

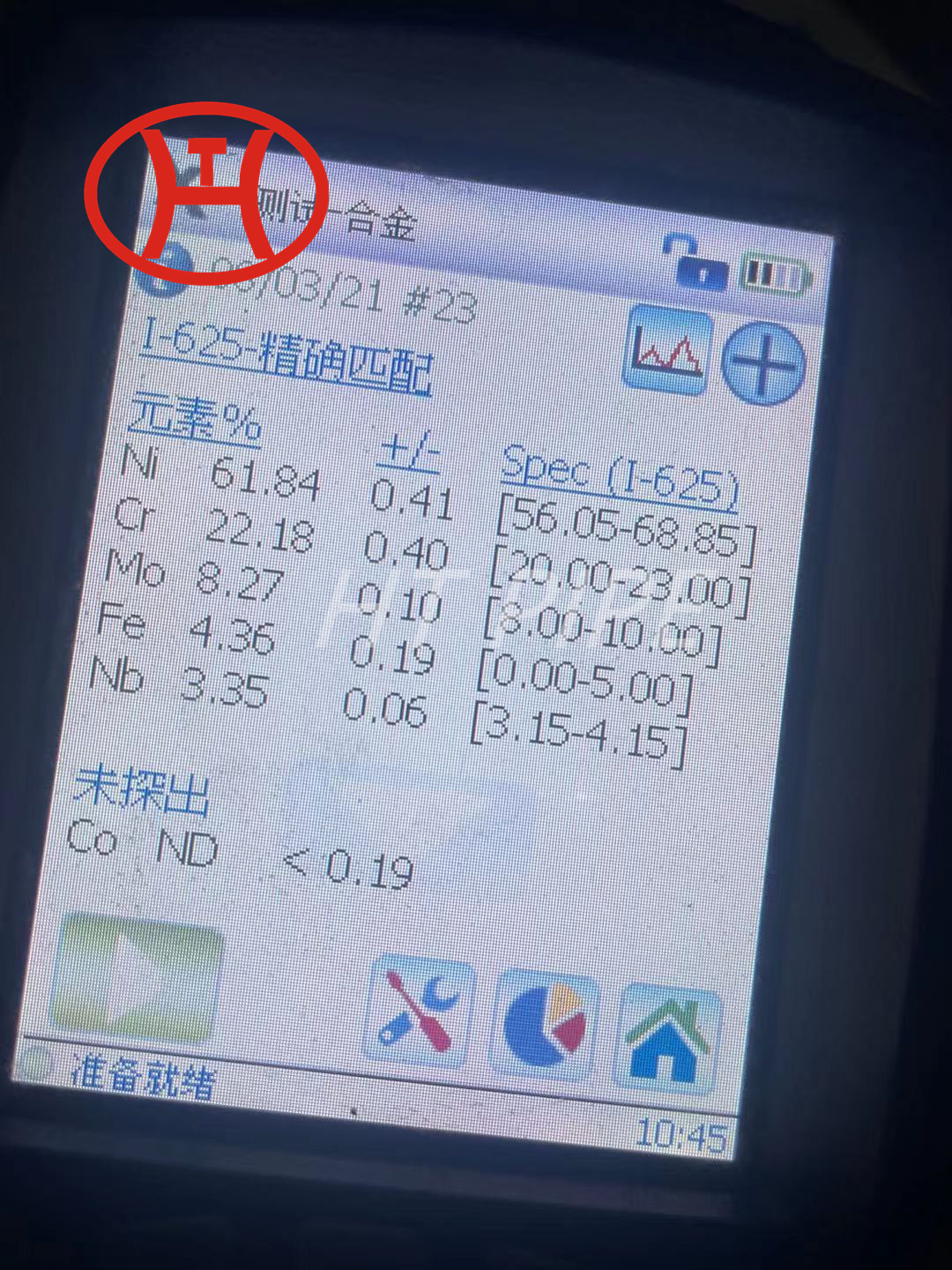

For the production of Monel K500 flanges, our expert follows national and international quality standards. For this purpose, we select excellent quality raw material such as Monel K500. We maintain the entire record of the performed test and offer the best quality Monel K500 Flanges to customers. We manufacture Monel K500 Flanges by using an alloy of Nickel and Copper. The material provides excellent resistance against corrosive materials and solutions like oxidizing salt, acids, nitrates, and other oxidizing agents. Also, alloy offers superior strength and hardness to finished product. Our Monel K500 Flanges can actively work in harsh operational environments. While most of the characteristics of Monel K500 Flanges are analogous to monel 400, the former alloy has added bonus of enhanced tensile strength and hardness properties. Over and above the nickel copper base, elements like aluminium and titanium in the chemistry of the Monel K500 Lap Joint Flange proves to be very fruitful.