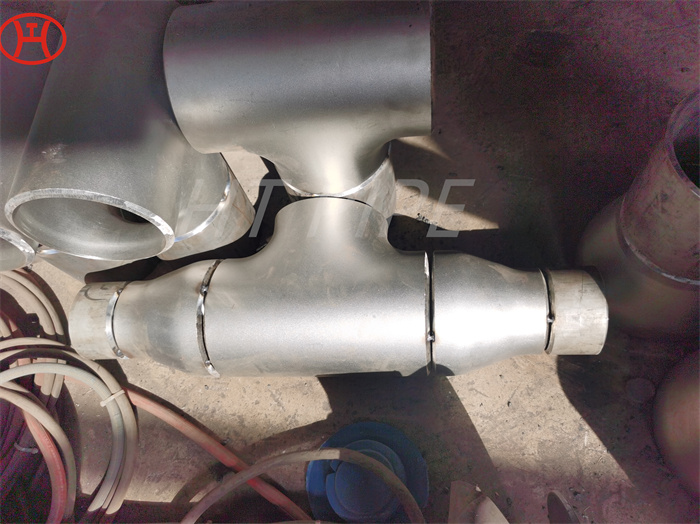

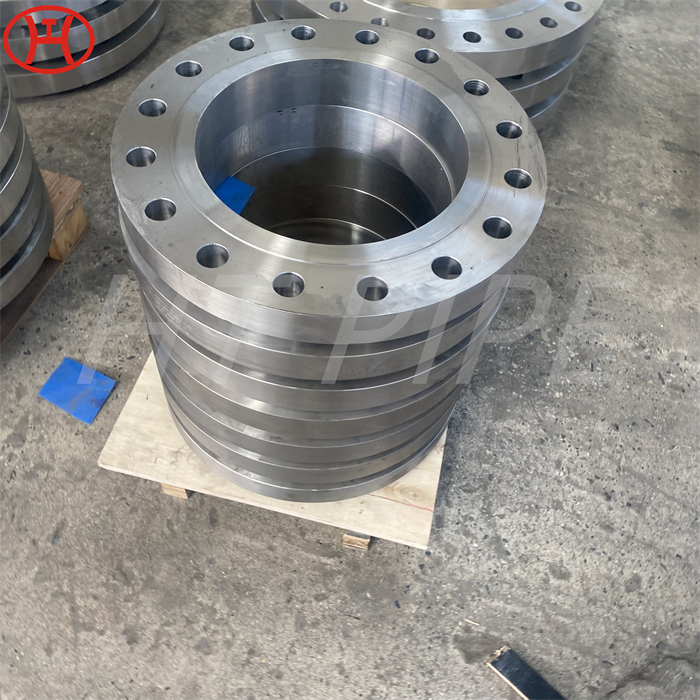

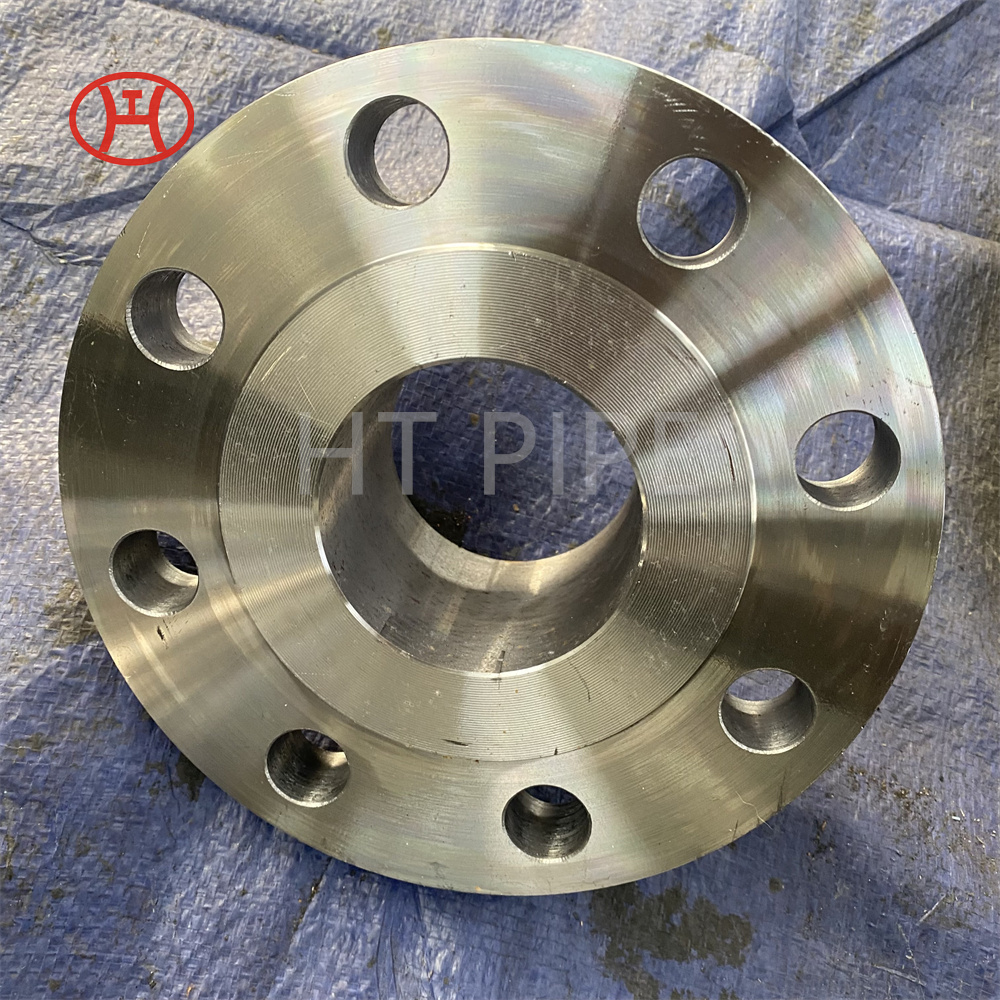

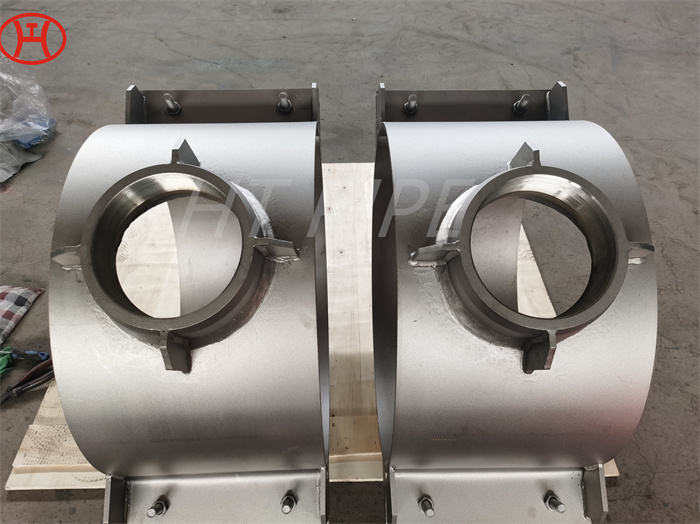

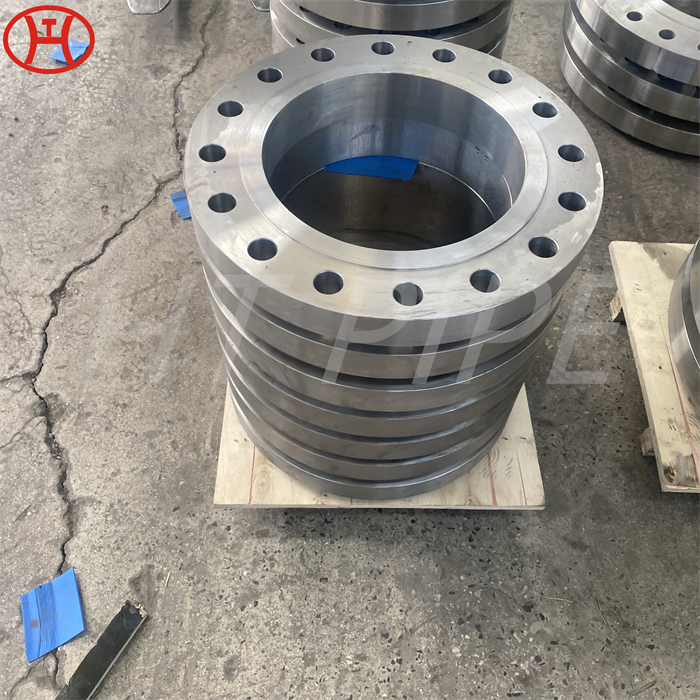

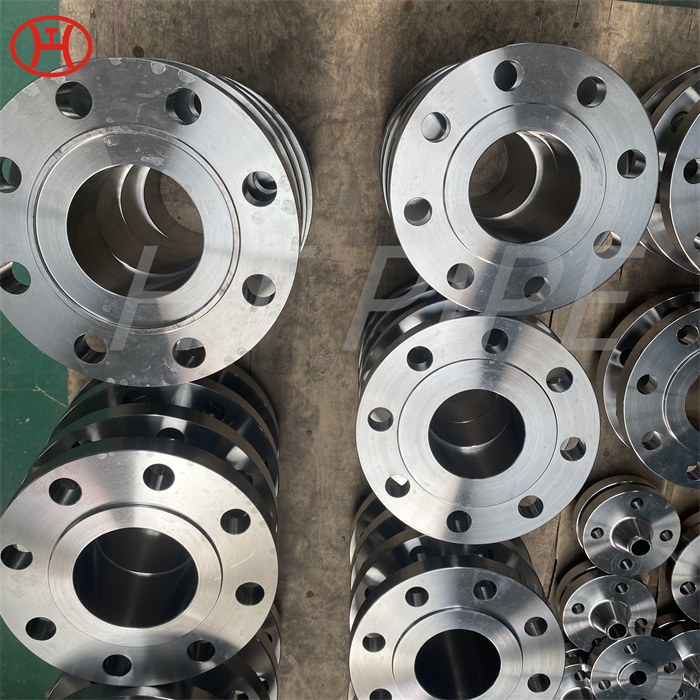

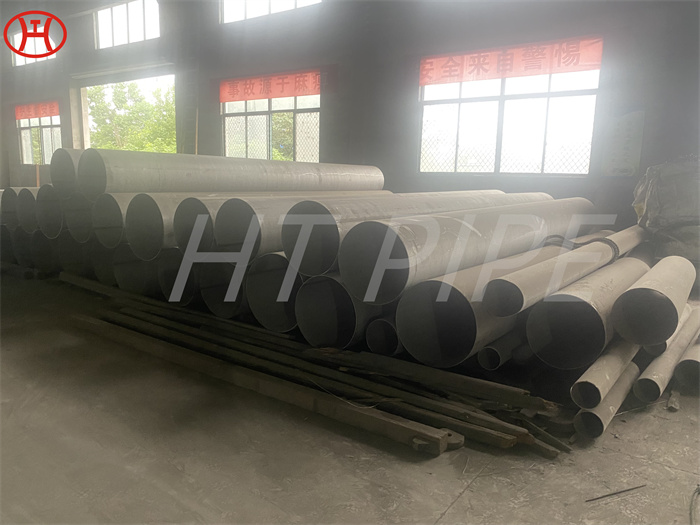

Monel K500 N05500 heat pipes with BL flanges

Monel K-500 combines the excellent corrosion resistance of Monel 400 with the added benefits of higher strength and hardness. Performance can be improved by adding aluminum and titanium to the nickel-copper matrix and by heating under controlled conditions to precipitate submicroscopic particles of Ni 3 (Ti, Al) throughout the matrix.

Monel K500 is a precipitation hardenable nickel-copper alloy that combines the excellent corrosion resistance of Monel 400 with the added benefits of higher strength and hardness. These enhanced properties, strength and hardness are obtained by the addition of aluminum and titanium to the nickel-copper matrix and by heat treatment (often called age hardening or aging) used to affect precipitation.

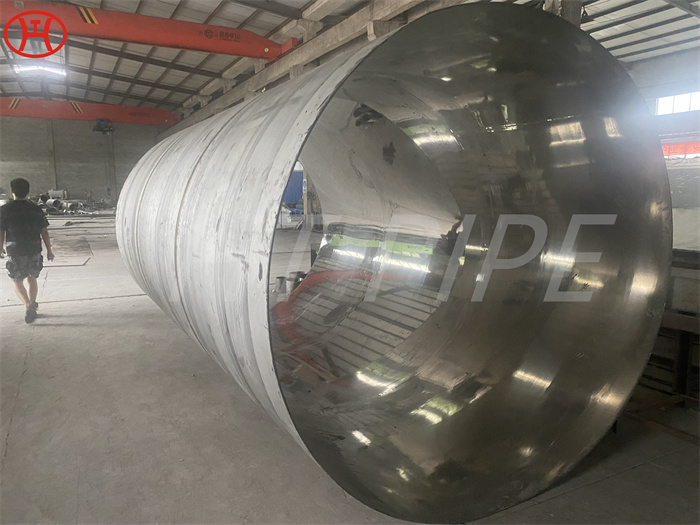

Monel K-500 is also known for its ease of manufacture compared to other superalloys, and it is essentially non-magnetic even at low temperatures. Typical applications for K-500 alloy are pump shafts and impellers; scrapers and scrapers; oil well collars and instrumentation; electronic components; springs; and valve trims.