Monel K500 pipe bend and elbow added strength and hardness of aluminium and titanium

The corrosion resistance of Monel alloy K-500 is subtantially equivalent to that of alloy 400 except that, when in the age-hardened condition, alloy K-500 has a greater tendency toward stress-corrosion cracking in some environments.

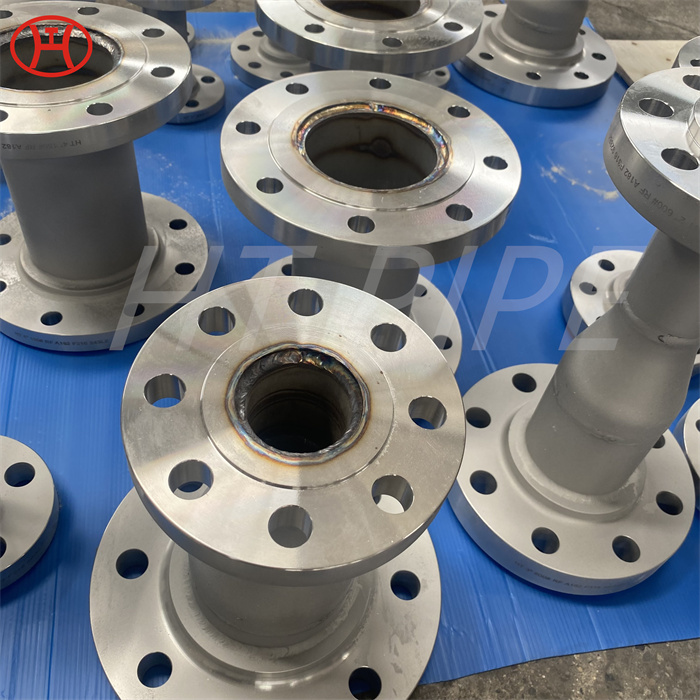

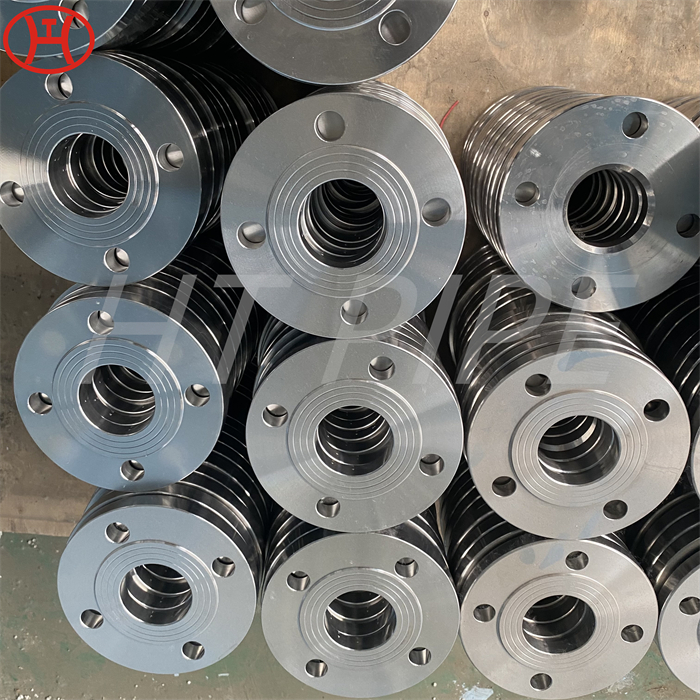

The addition of aluminum and titanium make the DIN 2.4375 alloy even stronger. The alloy could be work hardened. This has advantages and disadvantages. Since it is easy to work harden, machining has to be done slowly because the alloy tends to harden faster. The Monel K500 pipe bend and elbow price varies depending on the market conditions and the availability. The regular welding process for Monel K-500 is gas tungsten arc welding(GTAW) with Monel filler metal 60. It can be readily hot formed or cold formed. The maximum hot working temperature is 2100¡ãF while cold forming can only be accomplished on annealed materials. The regular heat treatment for Monel K-500 pipe bend and elbow usually involve both annealing (either solution annealing or process annealing) and age-hardening procedures.