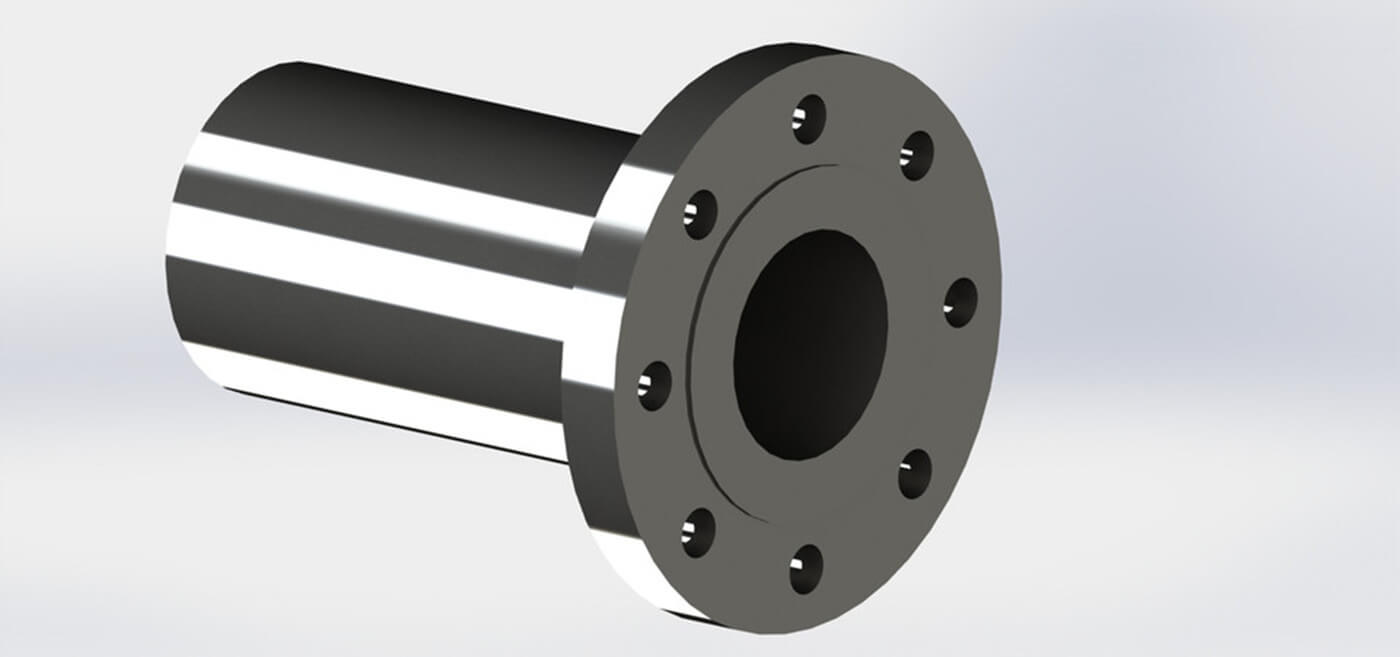

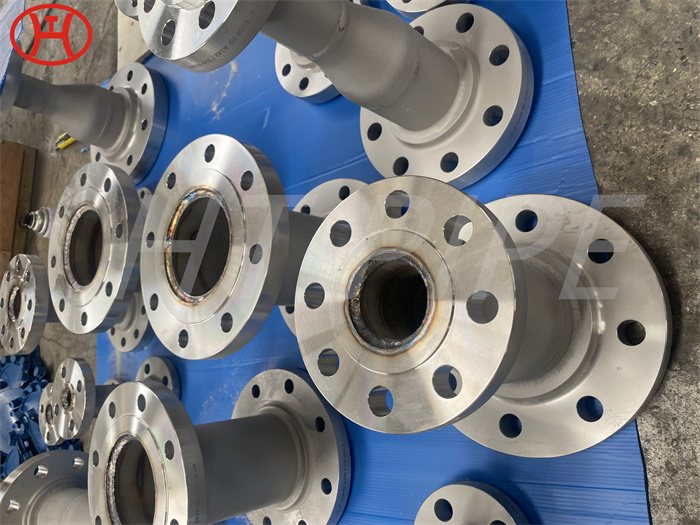

Monel K500 pipe bend and elbow for Oil well industry and Doctor blades and scrapers

Monel nickel-copper alloy K-500 pipe bend and elbow combine the excellent corrosion resistance characteristic of Monel alloy 400 with the added advantages of greater strength and hardness.

Correctly produced Alloy K-500 can be hot or cold worked and subsequently heat treated in order to create an alloy with high strength and toughness compared to the basic alloy. It also has low permeability and is nonmagnetic to under -100¡ãC[-150¡ãF]. The increased properties are obtained by adding aluminum and titanium to the nickel-copper base, and by heating under controlled conditions so that submicroscopic particles of Ni3 (Ti, Al) are precipitated throughout the matrix. The use in oil extraction, marine and chemical processing sectors for fasteners and valve internals uses this ability to the full. These amplified properties, strength, and hardness, are obtained by adding aluminum and titanium to the nickel-copper base and by a thermal processing used to effect precipitation, typically called age hardening or aging. When in the age-hardened condition, Monel K-500 has a greater tendency toward stress-corrosion cracking in some environments than Monel 400. Alloy K-500 has approximately three times the yield strength and double the tensile strength when compared with alloy 400.