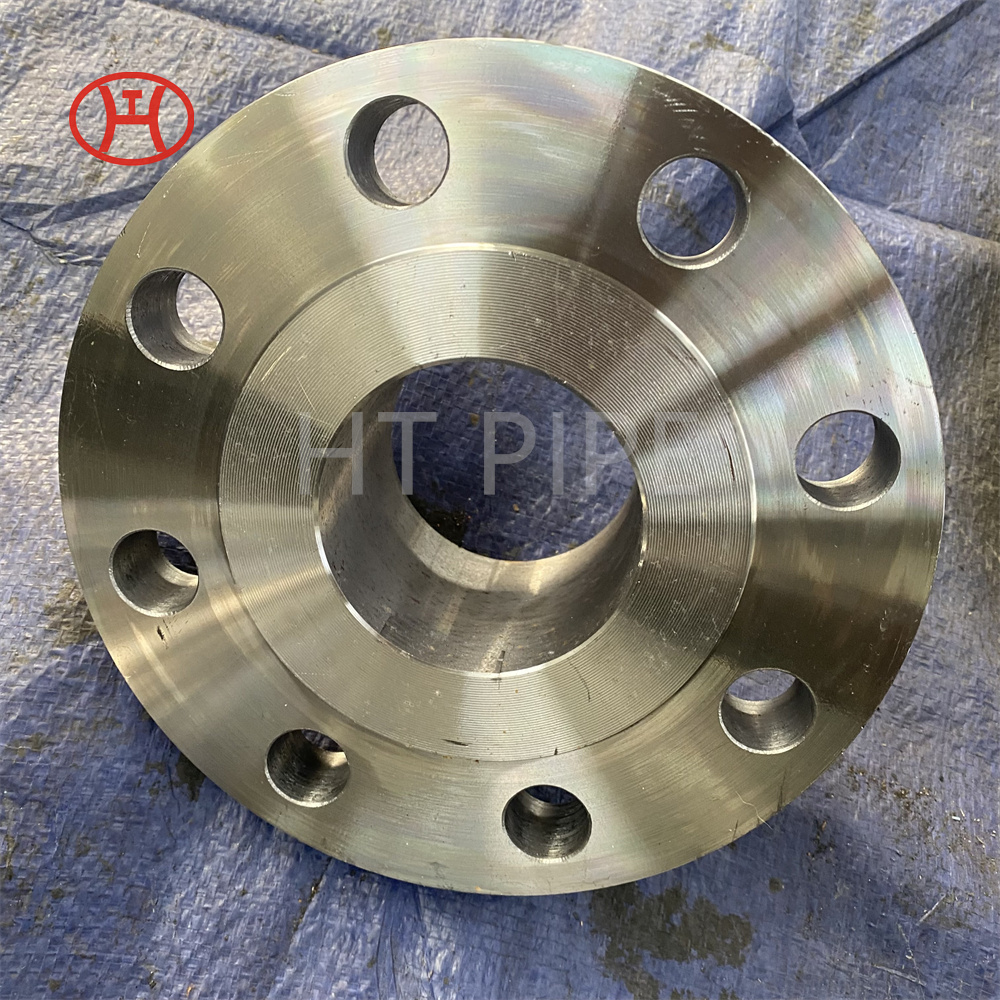

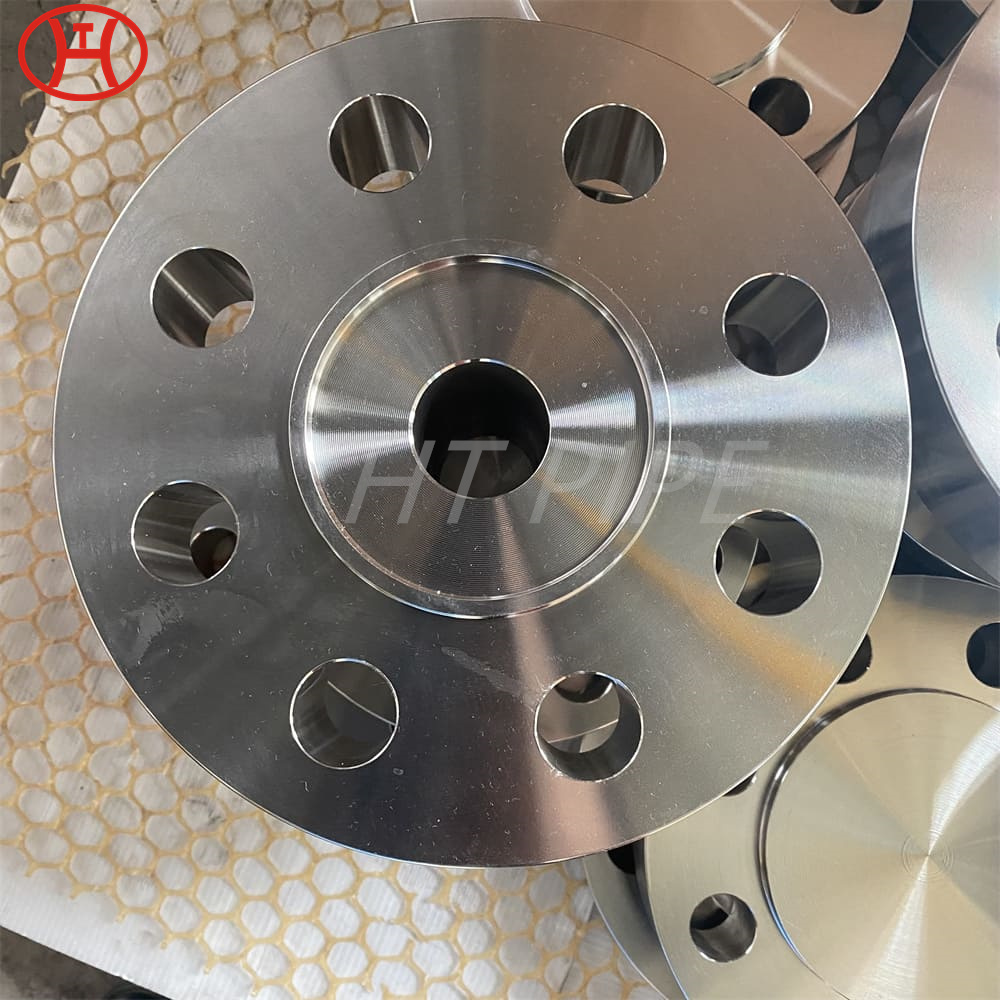

Monel K500 pipe bend and elbow highly resistant to chlorine related stress corrosion cracking

The combination of very low corrosion rates in high-velocity sea water and high strength make alloy K-500 pipe bend and elbow particularly suitable for shafts of centrifugal pumps in marine service.

The Monel K500 specification includes the gamma prime formation which occurs with aging. This layer acts as a boundary between the corrosive agents and the alloy material. There is pitting corrosion in the beginning but it slows down and then remains without corrosion with age. The combination of very low corrosion rates in high-velocity sear water and high strength make Monel K-500 particularly suitable for shafts of centrifugal pumps in marine service. In stagnant or slow-moving sea water, fouling may occur followed by pitting but this pitting slows down after a fairly rapid initial attack. Due to these properties of the alloy, it is used in water pump shafts, impellers, propellers, oil well drill collars, electronic components and other high end accessories. The Monel K500 heat treatment makes it harder. Once hardened, cold working and machining become very tough. The applications also span into centrifugal pumps used in the marine industry, propeller shafts and valve components and some other ship and boat accessories.