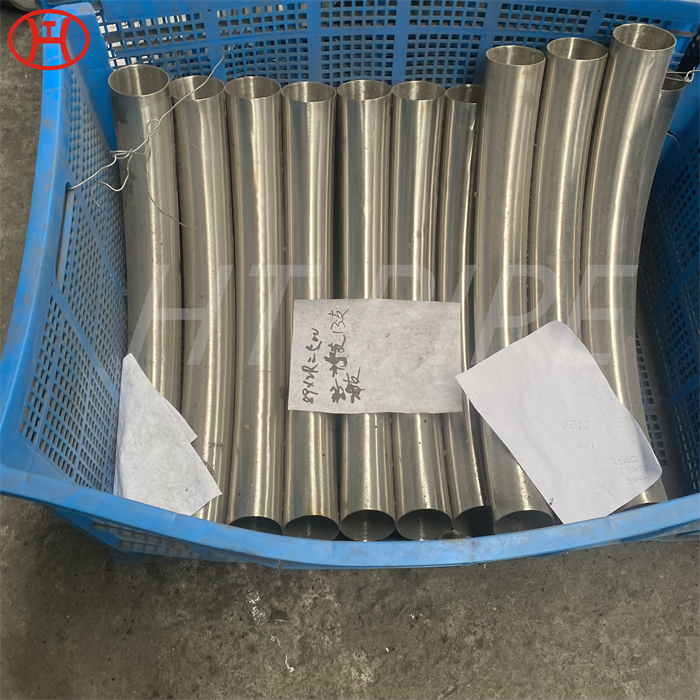

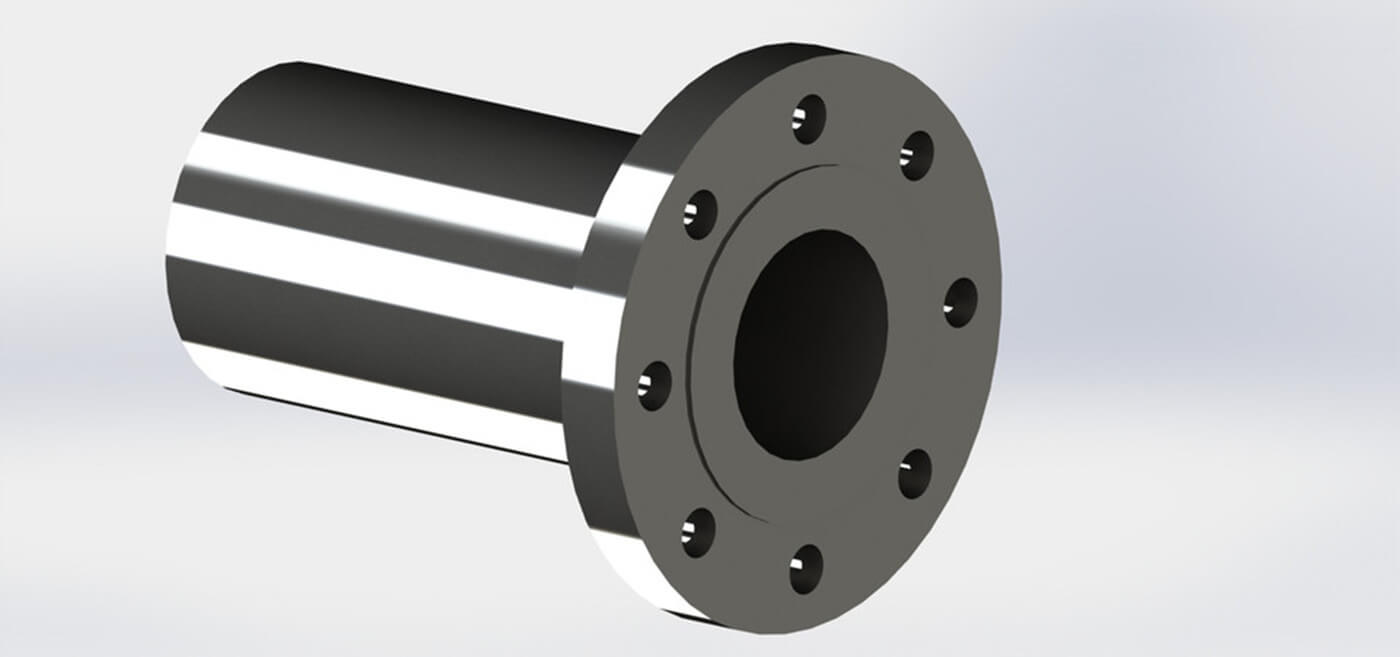

Monel K500 pipe bend and elbow offers excellent mechanical properties from sub-zero temperatures up to about 480C

MONEL K500 retains the excellent corrosion resistant characteristics of 400 and has enhanced strength and hardness after precipitation hardening when compared with 400.

Monel K500 pipe bend and elbow are heat-treated under controlled conditions to precipitate submicroscopic particles of Ni3 (Ti, Al) throughout the material. It should be noted that age-hardened Monel K500 is more prone to stress-corrosion cracking than Monel 400. This alloy provides excellent corrosion resistance in a range of environments including sea water, hydrofluoric acid, sulphuric acid and alkalis. It has found to be resistant to a sour-gas environment and is listed within NACE MR1075. Its basic composition is similar to that of ALLOY400 but the alloying additions make it age hardenable under controlled conditions of temperature and time.