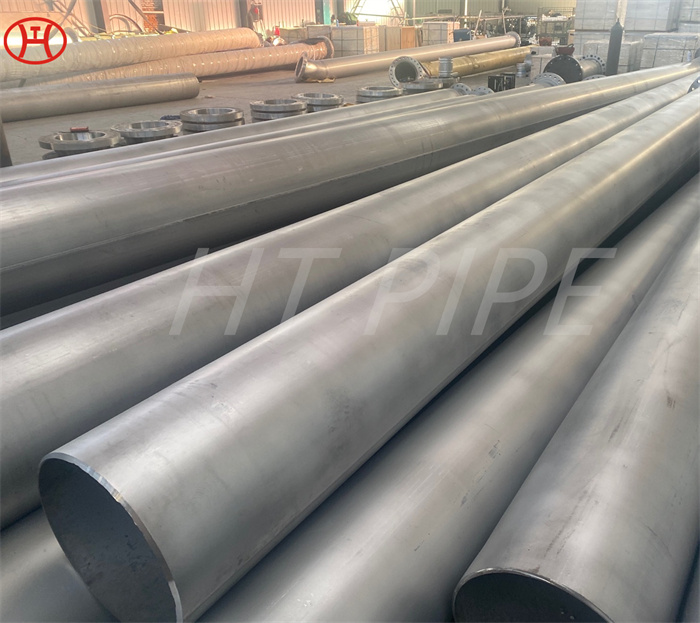

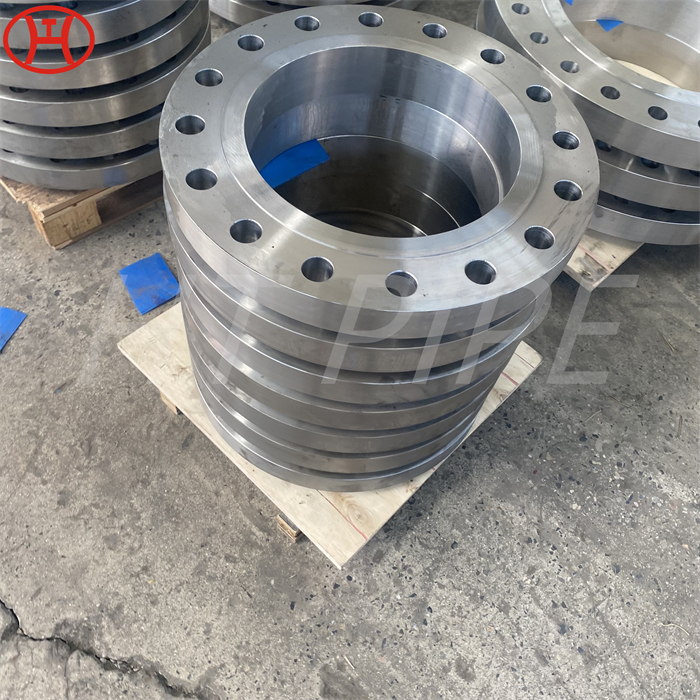

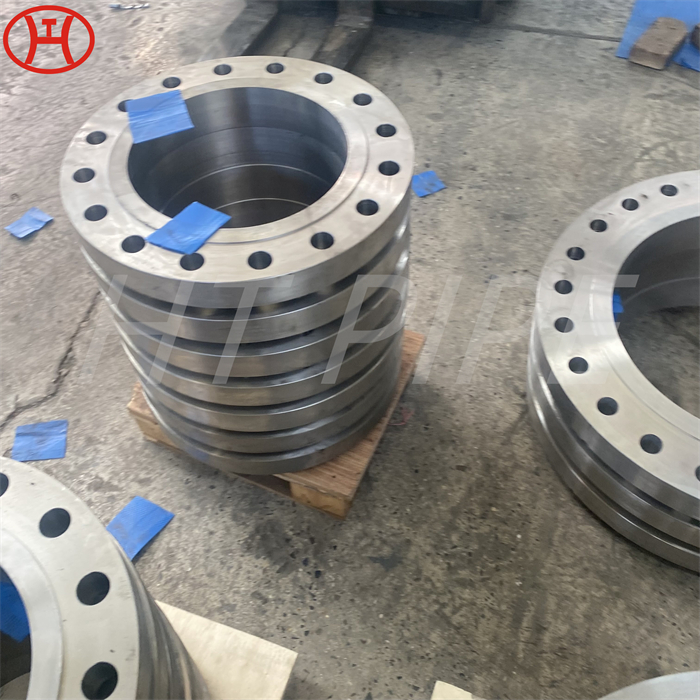

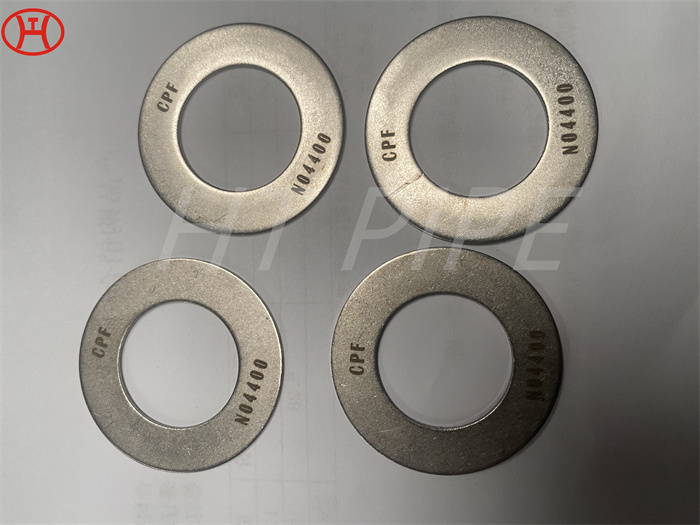

Monel K500 pipe bend and elbow offers excellent resistance to corrosion in both oxidizing as well as reducing environments

Monel alloy K-500 pipe bend and elbow have been found to be resistant to a sour-gas environment. After 6 days of continuous immersion in saturated (3500ppm) hydrogen sulfide solutions at acidic and basic pH’s (ranging from 1.0 to 11.0), U-bend specimens of age-hardened sheet show no cracking.

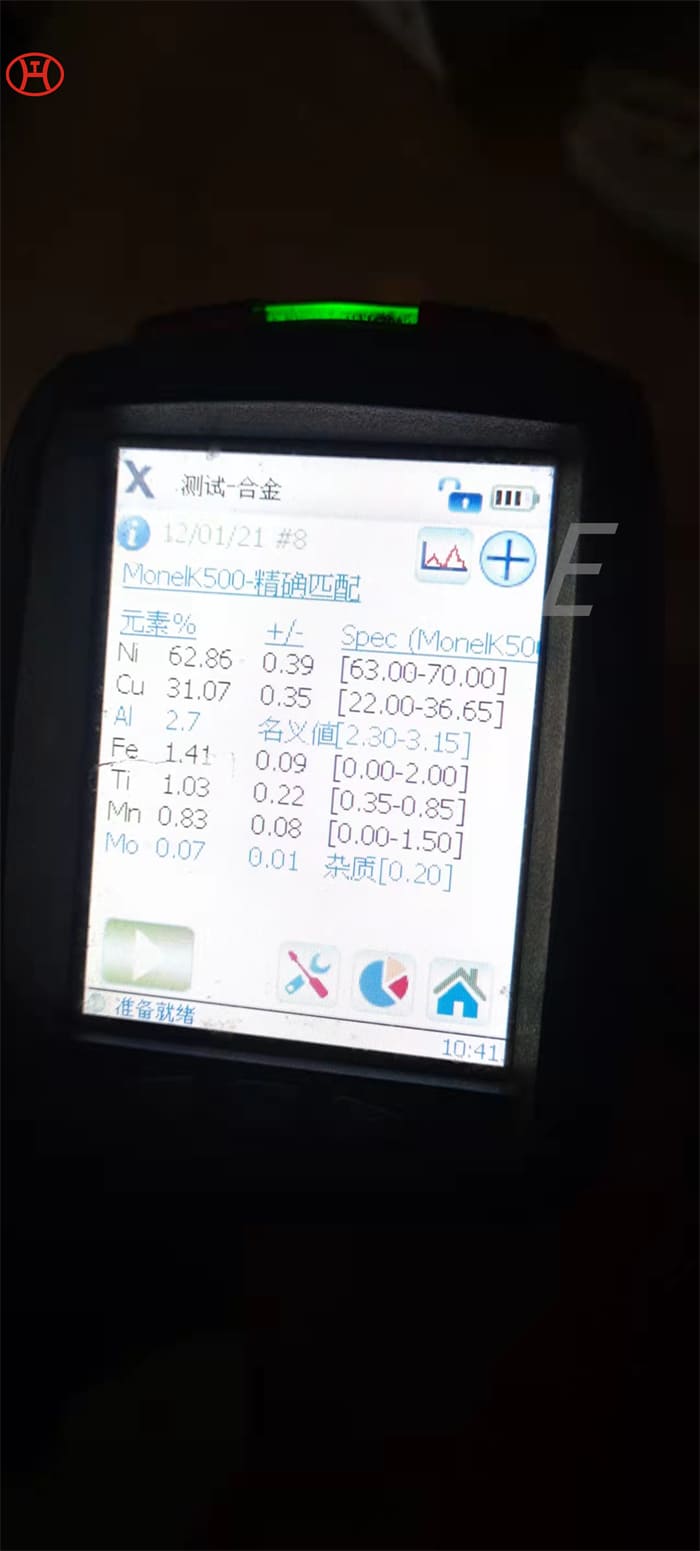

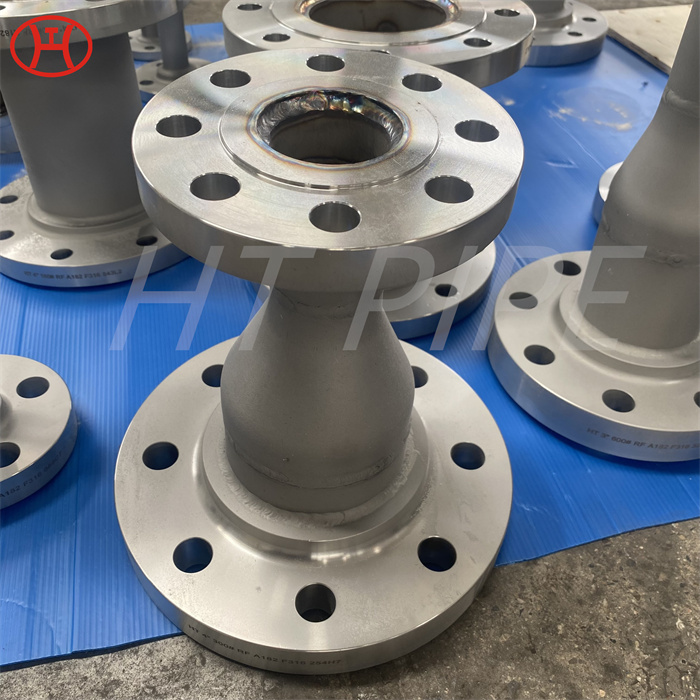

Aluminum and copper may be selectively oxidized during heating, leaving a magnetic nickel rich film on the outside. Pickling or bright dipping in acid can remove this magnetic film and restore the non-magnetic properties. The corrosion resistance of alloy K-500 is substantially equivalent to that of Monel? 400 except that when in the age-hardened condition, nickel alloy K-500 has a greater tendency toward stress-corrosion cracking in some environments. Monel K-500 pipe bend and elbow have been found to be resistant to a sour-gas environment. We can provide you with a full pricelist upon contact. The Monel K500 machinability is less and therefore machining is done before precipitation hardening. The Monel K500 pipe bend and elbow could be age hardened as well. The alloy could perform under cryogenic temperatures and up to very high temperatures.