Monel K500 pipe bend and elbow offers stress corrosion cracking in certain environments

Monel K500 pipe bend and elbow are virtually nonmagnetic, even at quite low temperatures

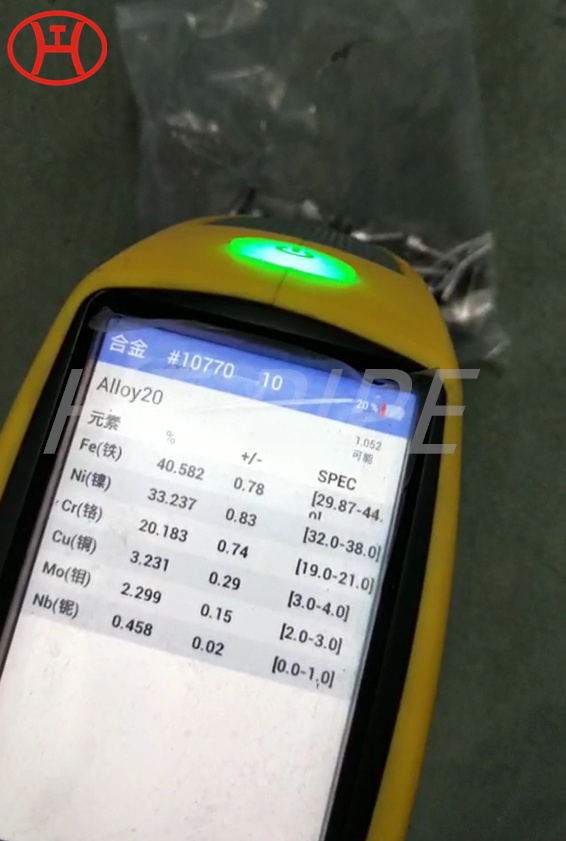

Alloy K500 is a nickel copper alloy which combines the excellent corrosion resistance of Alloy 400 pipe bend and elbow with the added advantages of greater strength and hardness. The increase in strength and hardness is a result of the precipitation hardening capability gained by the additions of titanium and aluminum. Alloy K500can be cold rolled to achieve the temper properties required by specific customers and/or manufacturing requirements. MONEL alloy K-500 is designated as UNS N05500 and Werkstoff Nr. 2.4375. It is listed in NACE MR-01-75 for oil and gas service. Monel K500 is a precipitation-hardenable nickel-copper alloy that combines the excellent corrosion resistance characteristic of Monel 400 with the added advantage of greater strength and hardness. These amplified properties, strength and hardness, are obtained by adding aluminum and titanium to the nickel-copper base and by a thermal processing used to effect precipitation, typically called age hardening or aging. This alloy has the corrosion resistance of Monel 400 Alloy together with greater strength and hardness. Aluminum and titanium additions, plus controlled heat treat cycles, are responsible for the added strength of this alloy.