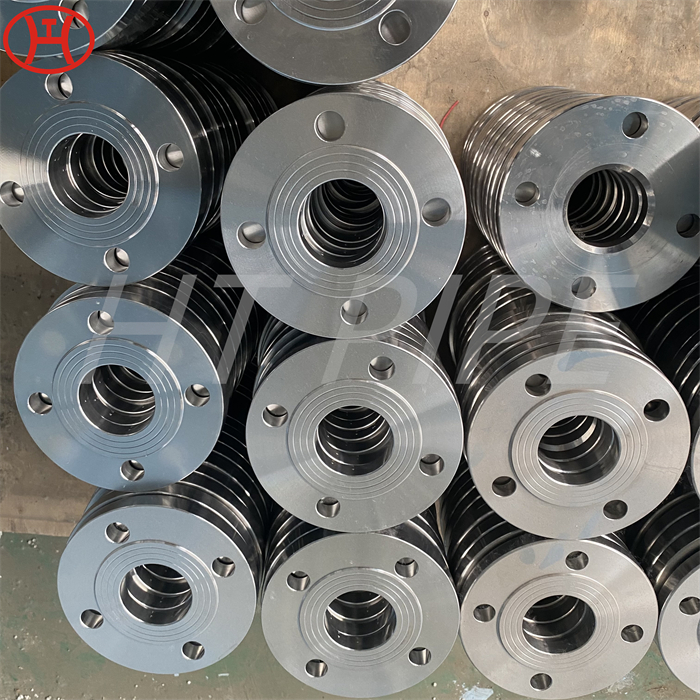

Monel K500 pipe bend and elbow useful in sour gas environments

Monel K500 pipe bend and elbow are exceptionally good dimensional stability.

When in the age-hardened condition, Monel K-500 has a greater tendency toward stress-corrosion cracking in some environments than Monel 400. Alloy K-500 has approximately three times the yield strength and double the tensile strength when compared with alloy 400. Some typical applications for K-500 alloy are chains and cables, fasteners and springs for marine service; pump and valve parts for chemical processing; doctor blades and scrapers for pulp processing in paper production; oil well drill collars and instruments, pump shafts and impellers, and safety lifts and valves for oil and gas production. Monel K500 pipe bend and elbow are mainly focused on producing some of the strongest manufactured parts. It¡¯s not just limited to iron and steel forging but as well as other metals also. Compared to other manufacturing process, Monel K500 pipe bend and elbow are mainly focused on producing some of the strongest manufactured parts. It¡¯s not just limited to iron and steel forging but as well as other metals also.