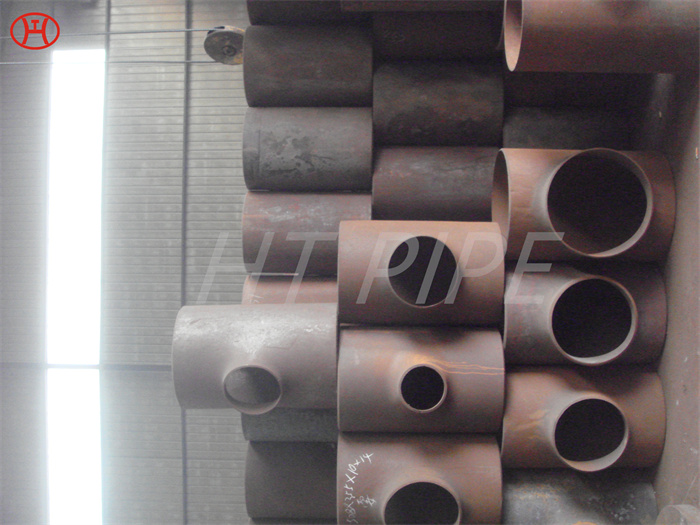

monel K500 steel pipe fittings

During the aging process, Monel K500 butt welded pipe fittings experience a slight permanent reduction, but a slight warpage occurs due to the entanglement of low heat and slow cooling rates.

If Monel K500 end cap fittings are cold worked, the temperature should be 1900 degrees Fahrenheit. The heat treatment of Monel K500 Disc Lid fittings used to produce precipitates is commonly referred to as age hardening or aging. Adding aluminum and titanium to an already strong nickel-copper base in Monel K500 Cross Fittings adds strength and stiffness. Monel K500 lateral tee fittings have been found to be resistant to sour gas environments. Monel K500 long and short end fittings have similar properties to Monel 400 fittings in terms of corrosion resistance, but have higher yield and tensile strengths.