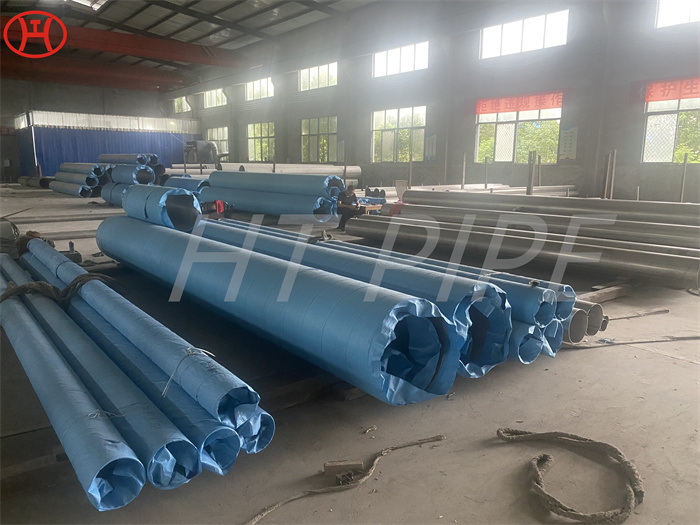

Monel K500 tube and pipe combines the excellent corrosion resistance characteristic of Monel alloy 400

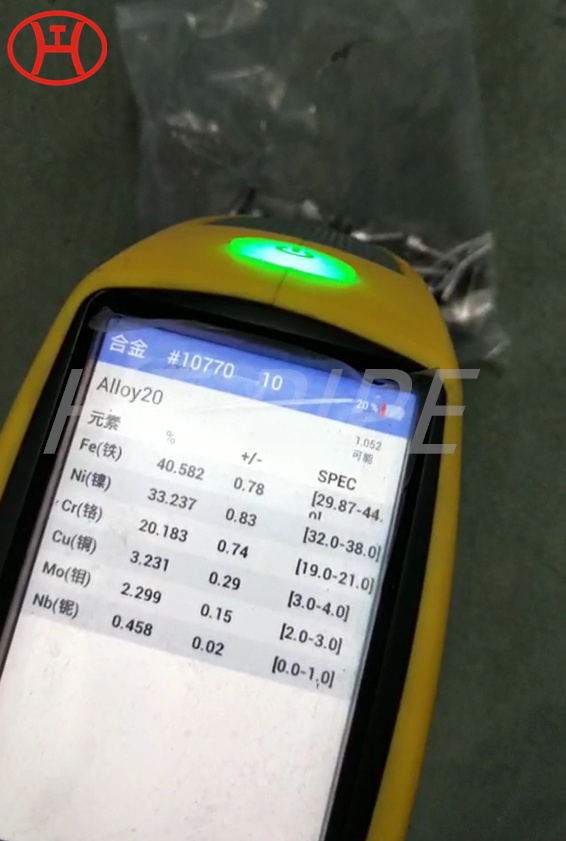

Monel K500 has about three times the yield strength and twice the tensile strength of Monel 400, and higher mechanical properties can be obtained by cold working or age hardening. Monel K500 alloy has the same corrosion resistance as Monel 400 alloy.

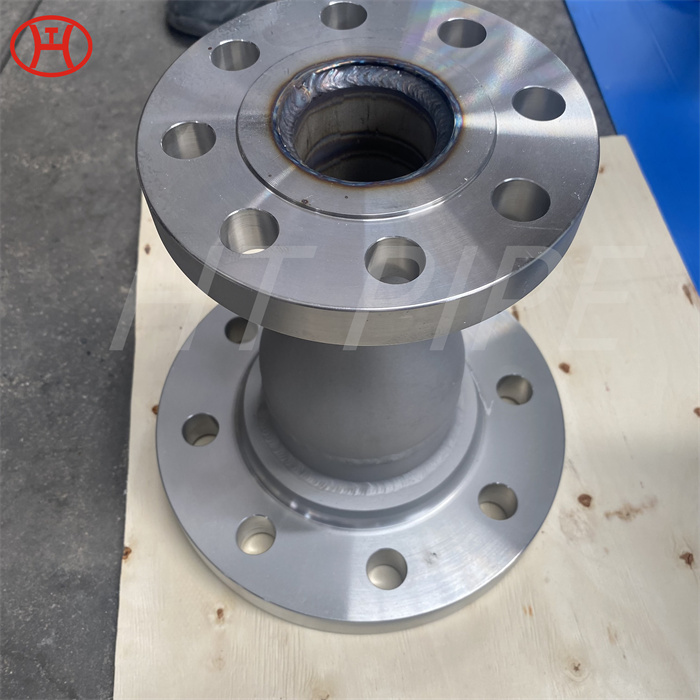

Monel K500 alloy is based on Monel 400 alloy by adding 3.0% Al and 0.63% Ti to obtain age hardening ability. The alloy can be strengthened by aging at about 580¡ãC for 16 h after cold working. Its highest room temperature tensile strength can reach 1200 MN/m2, and its hardness can reach about 320 HV. Monel K500 alloy is mainly used for pump shafts and impellers, conveyor scrapers, oil well drilling rings, elastic parts, valve pads, etc. Others can also produce various heat exchange equipment, boiler feed water heaters, petroleum and chemical pipelines, containers, towers, tanks, valves, pumps, reactors, shafts, etc. Because of the low corrosion rate in flowing seawater and the high strength of this alloy, Monel K500 is suitable for making seawater corrosion-resistant centrifugal pump shafts. Applicable in sea water with stop and velocity.