Monel K500 tube and pipe stress-corrosion cracking in some environments

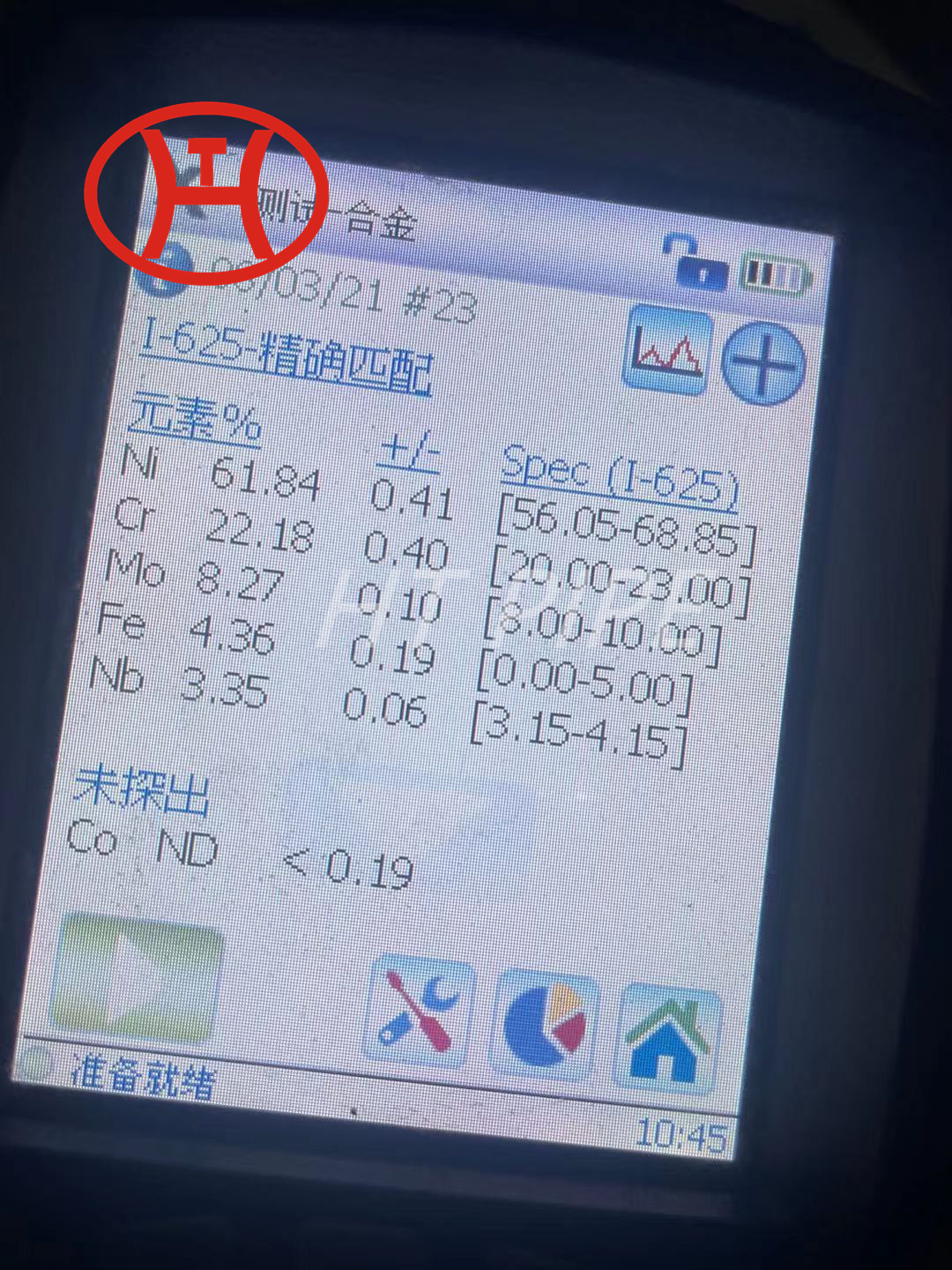

Using the fracture work theory calculation of impurity elements segregation at grain boundaries, it is shown that Mg, Cr and Co can improve the grain boundary bonding force of Ni-Cu alloy, so they can improve the high temperature plasticity of Monel K-500 alloy.

The annealed state is easy, and the aging state can also be processed. Usually large-scale machining in the annealed state, leaving a small amount of machining allowance to be machined to the final size after aging heat treatment. The aging state shrinks slightly after processing. Monel K500 alloy has good plasticity and toughness at low temperature, so cold working will not feel any difficulty, but in terms of hot working, the forming temperature is generally 871~1149 degrees, and the large deformation is between 1038~1149 degrees, but we recommend that the suitable temperature should be at 1093 degrees, and the alloy solution annealing temperature is 793~971, which can obtain good comprehensive properties. The temperature of hot-processed products should be 982 degrees, and that of cold-processed products should be 1038 degrees, but the heating time should be shortened as much as possible.