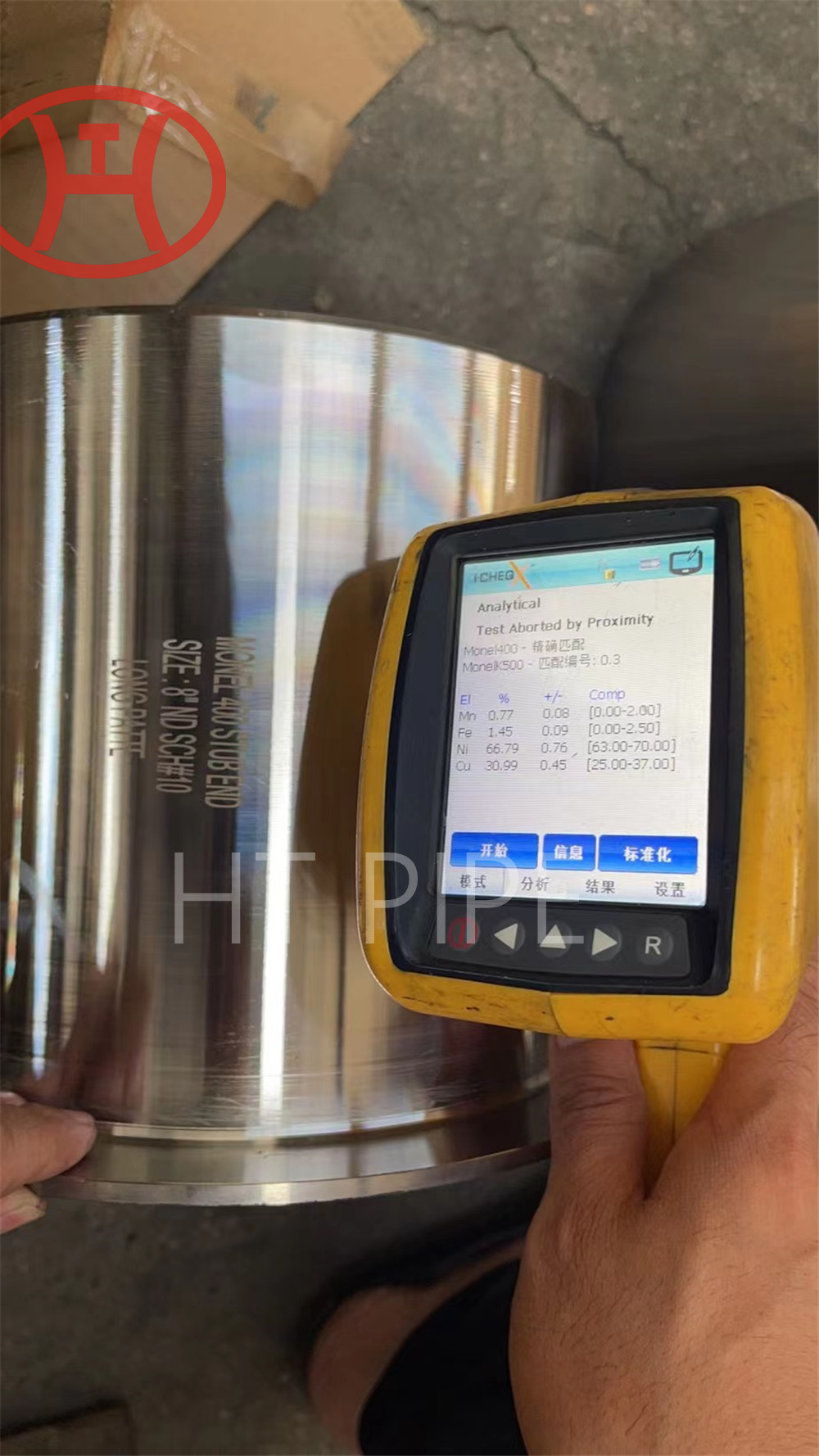

Monel K500 tube and pipe suitable for shafts of centrifugal pumps in marine service

The superposition of residual stress caused by cold working and aging thermal stress, as well as the preferential embrittlement of the surface layer at the initial stage of aging, are the main reasons for aging cracking of Monel K500 alloy.

Basic features The first is solid-state welding, that is, the welding material does not melt during the welding process, but is still in a solid state, and the weld is forged. Therefore, the welding zone will not produce some welding defects and welding embrittlement phenomena related to melting and solidification metallurgy, such as coarse columnar grains, segregation, crystal cracks, and isopores; secondly, the joint action of axial pressure and friction torque on the friction welding surface under and near some mechanical metallurgical surfaces. The role of gold, such as grain refinement, dense structure and dispersion distribution of inclusions, and the “self-cleaning” effect of friction welding surfaces, etc. This is very beneficial to obtain welded joints with the same strength as the base metal.