Monel K500 tube and pipe with the corrosion resistance of Monel alloy K-500

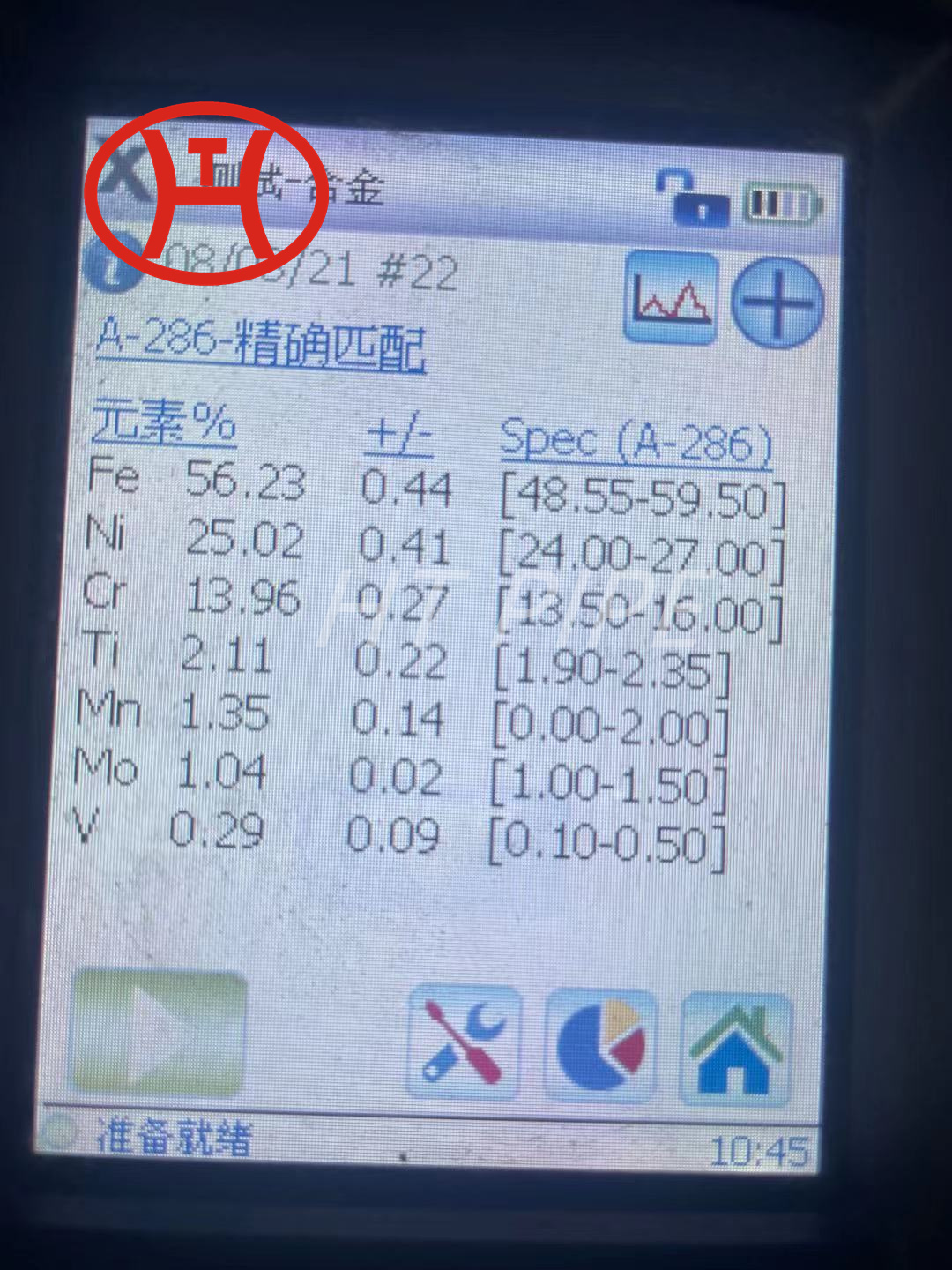

The high-temperature plasticity of the experimental alloy added with trace amounts of Mg, Cr and Co is obviously improved, and it exhibits certain superplasticity. At 1010¡æ, the strain rate sensitivity index m is 0.32, and the maximum elongation is 240%.

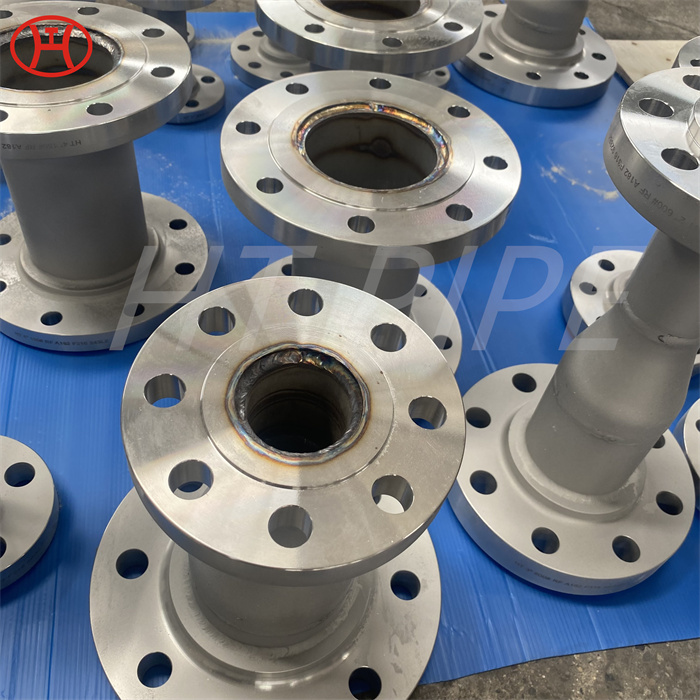

Monel K500 can be welded with common welding methods in the industry, but it must be carried out in the annealed state, and the stress must be relieved before aging. The aging process should be as fast as possible. Different welding methods choose different welding wires. Generally, Monel64 and 134 welding wires are selected.

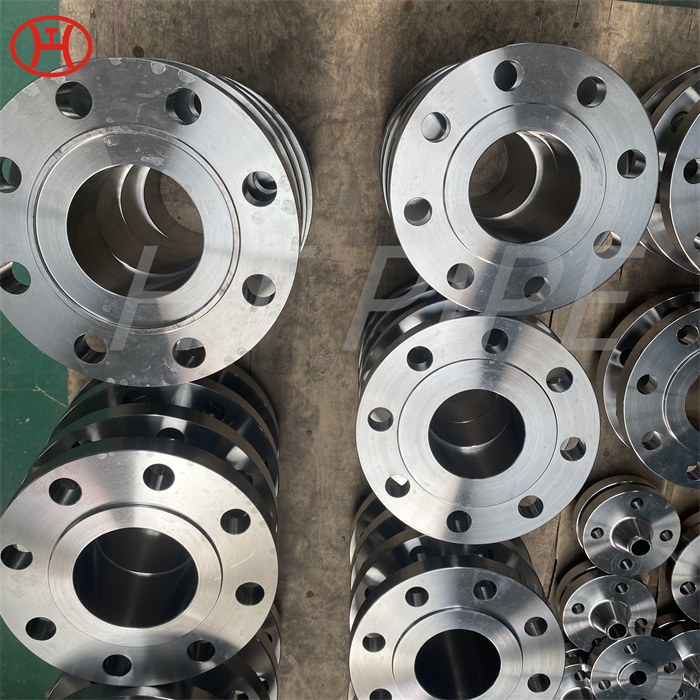

This alloy has comprehensive properties of toughness and corrosion resistance, and is widely used in chemical and other industries. Such as heaters, heat exchangers, evaporators, distillers, distillation towers, fatty acid treatment condensers, rosin acid treatment equipment, chemical pumps, etc. Because the alloy has high strength and good high temperature oxidation resistance, it can also be used in the heat treatment industry to manufacture various structural parts. In the nuclear power industry, this alloy has good corrosion resistance to high temperature and high pressure water, so it is also an important structural material for light water reactor nuclear power plants. Products are plates, rods, wires, strips and tubes.