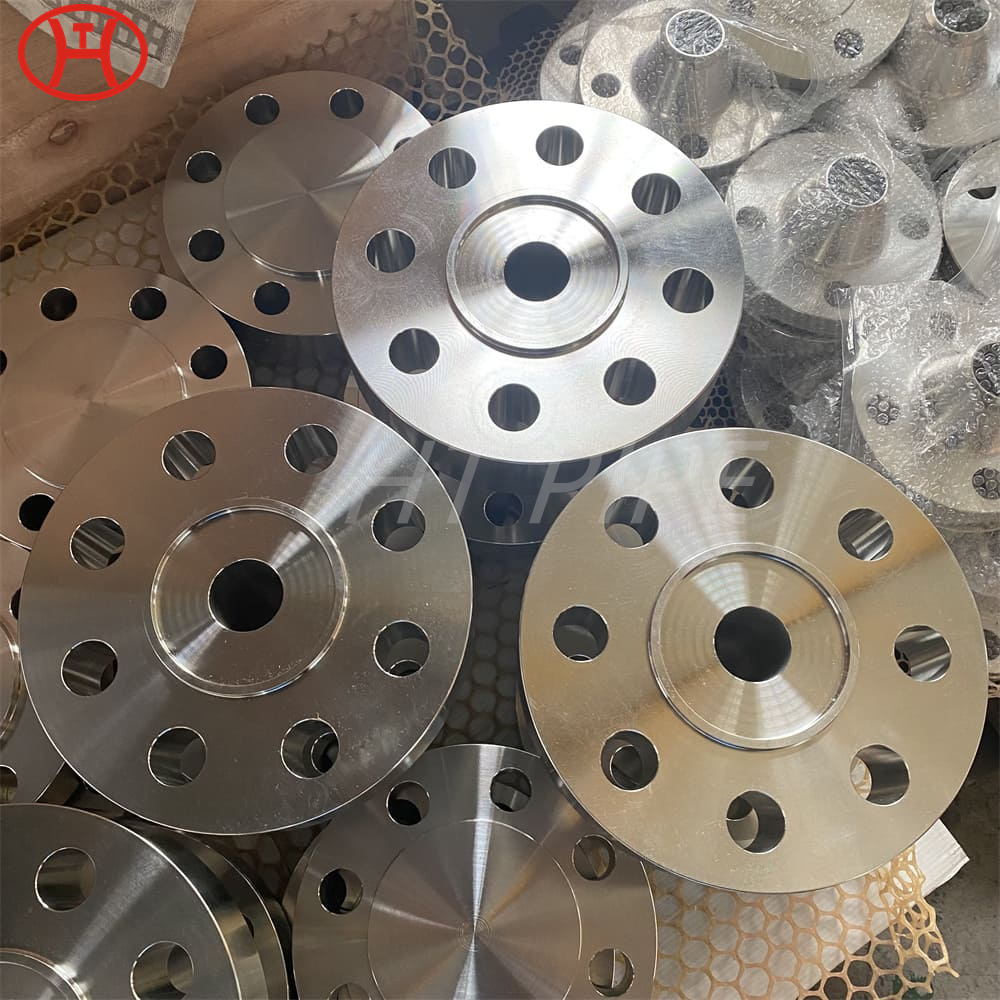

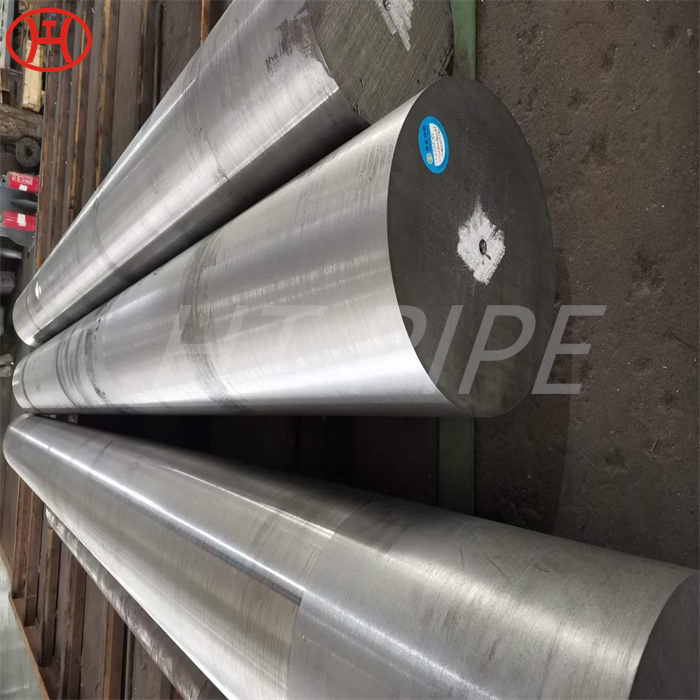

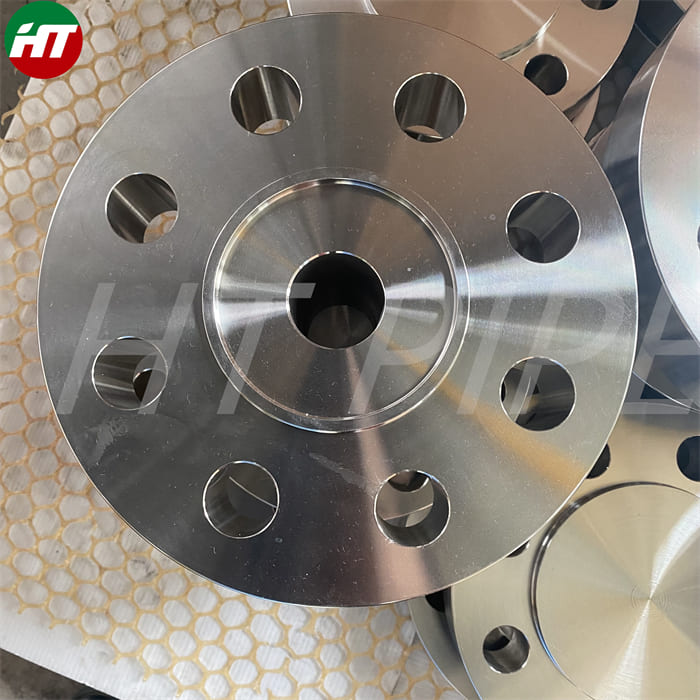

nickel alloy flange astm a351 cf3m price list nickel alloy puddle flange Inconel 718 flange WERKSTOFF NR. 2.4668 flange

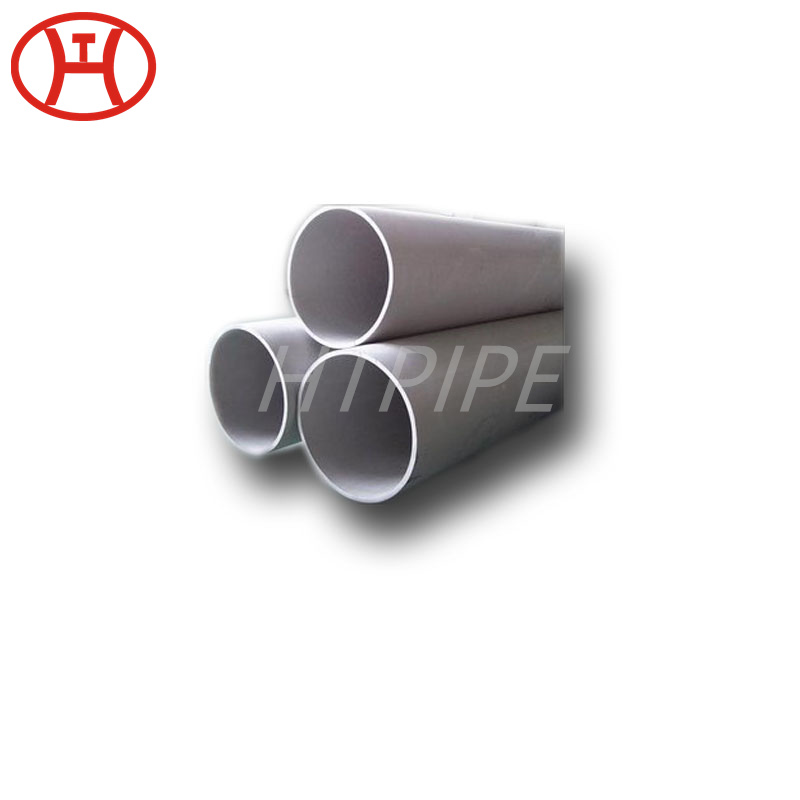

Inconel 718 alloy is also used in industries such as oil and gas drilling and production due to its high tensile strength and good corrosion resistance to chloride-related stress cracking and sulfide-related stress cracking. In these industries, Ams 5663 material has been used to manufacture various parts such as valves, pump shafts and wellhead components.

Inconel 718 flanges are used in many industrial applications due to their amazing properties. In Inconel flanges, the hot working process takes place at a temperature of 2050 degrees Fahrenheit. Inconel butt weld flanges are age hardenable and easily welded in aged conditions. Also, the alloy should not be soaked at this temperature for too much or for a long time. Uniform weight loss throughout the forging process will prevent the formation of a dual phase grain structure in the Ams 5663 material. Machining the alloy in the temperature range of 1700oF to 1850oF or 925oC to 1010oC will increase the strength of the forging if its subsequent service temperature drops below 1100oF or 595oC.