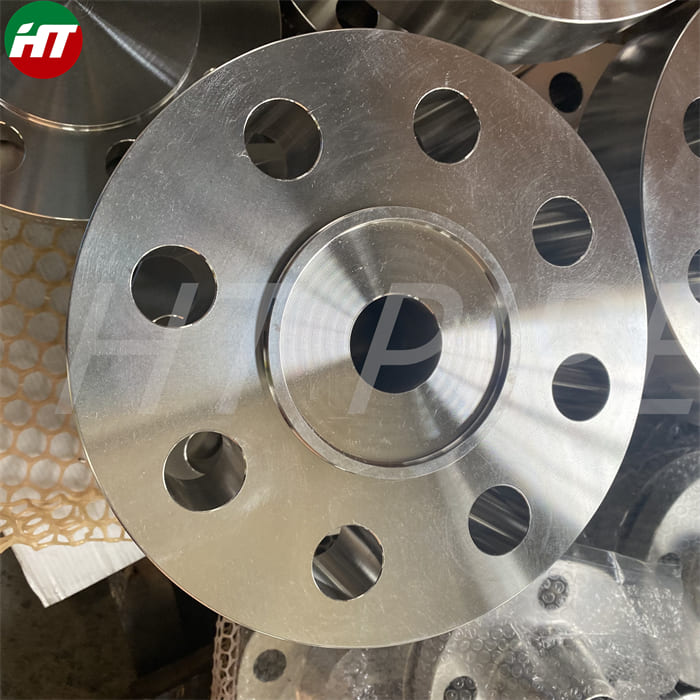

nickel alloy flange cap weight Inconel 718 flange WERKSTOFF NR. 2.4668 flange

Inconel 718 flanges are also ideal for a variety of applications in industry due to their purity and strength. Inconel 718 Socket Weld Flanges are used for hot extrusion dies, pump bodies and parts, etc. Inconel 718 lap flanges account for 50% of the world’s tonnage.

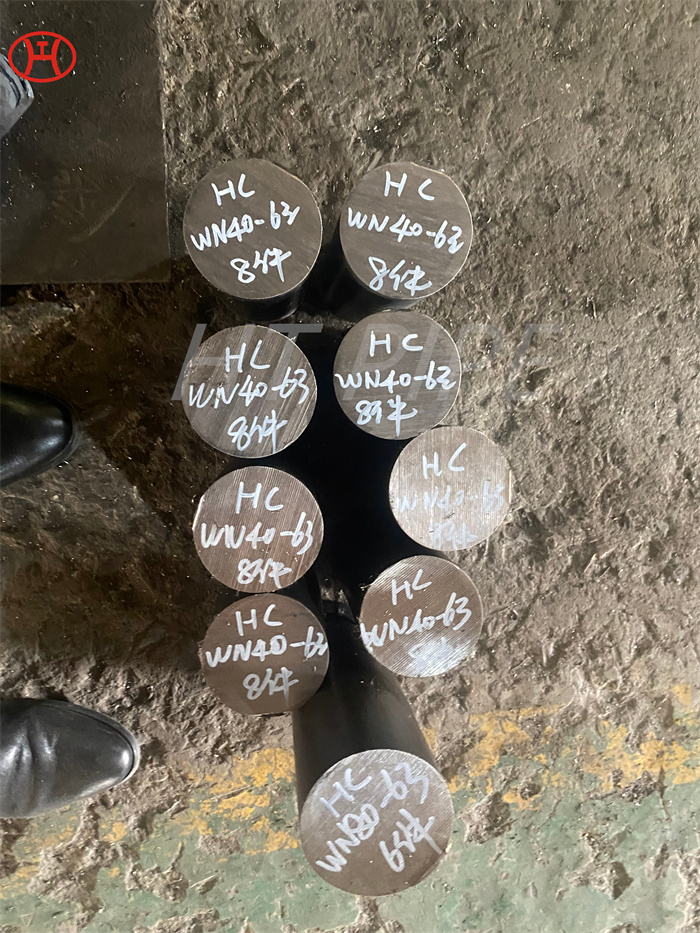

Astm B637 Uns N07718 Inconel 718 Forge Maker will heat the alloy at about 1950oF for 1 or 2 hours and then air cool. After this, the alloy is heated at approximately 1325oF for 8 hours. Once this is done, the material will be cooled in a temperature range of 100oF/hr to 1150oF for 8 hours and finally air cooled. At the same time, it can be used in the temperature range above 600 degrees Celsius. Here, the addition of niobium along with molybdenum is used to strengthen the base of the Inconel RTJ flange and does not require heat treatment to strengthen.