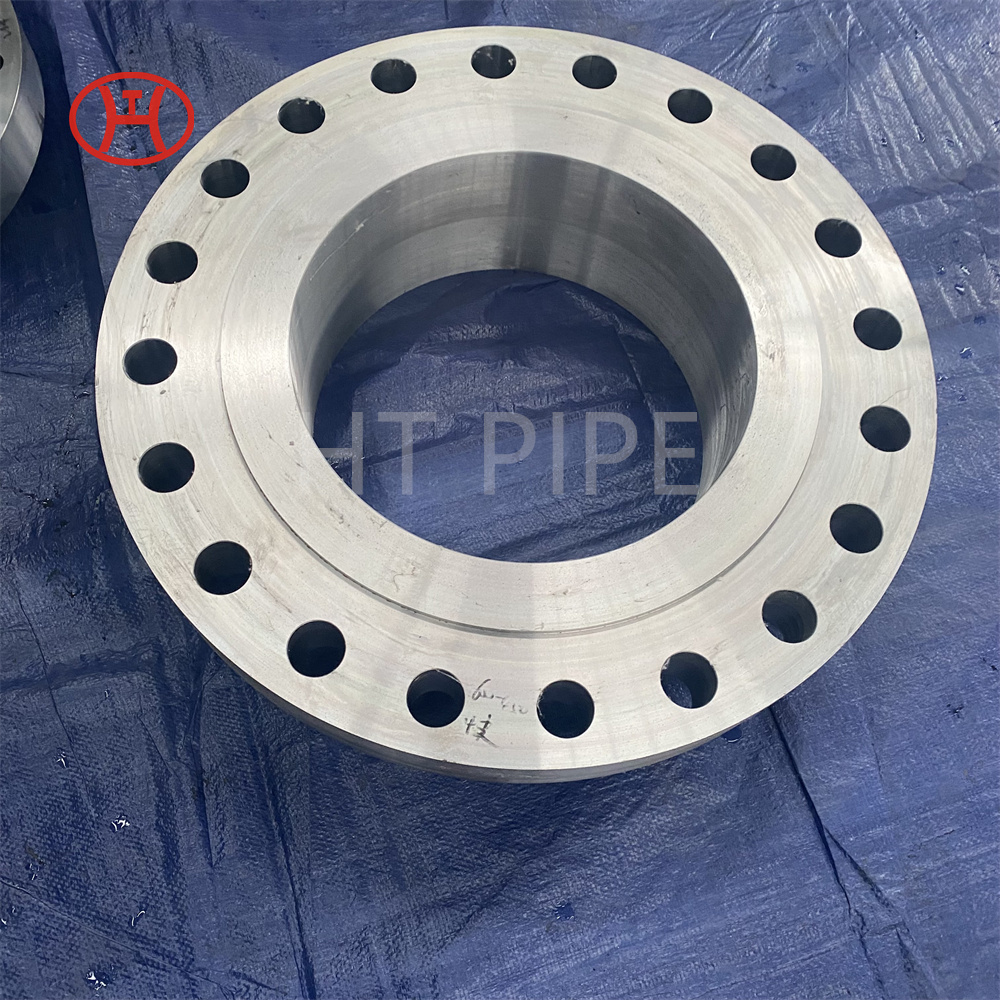

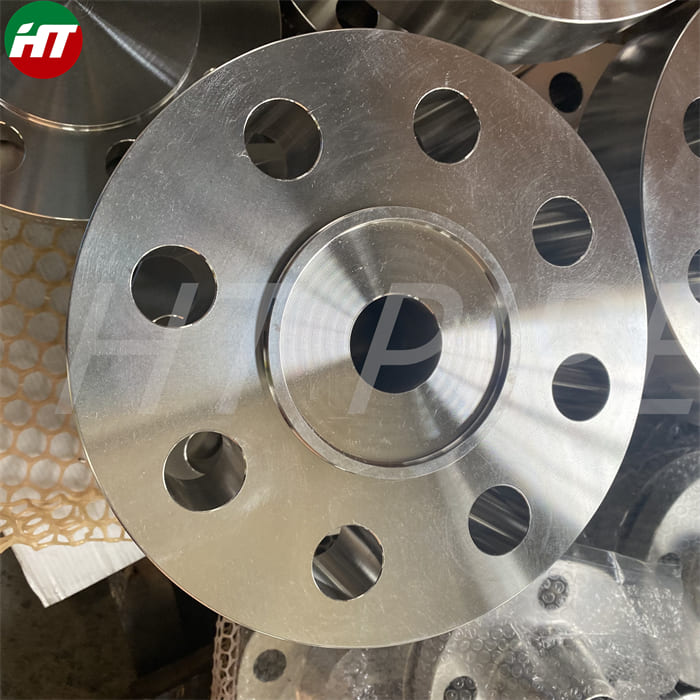

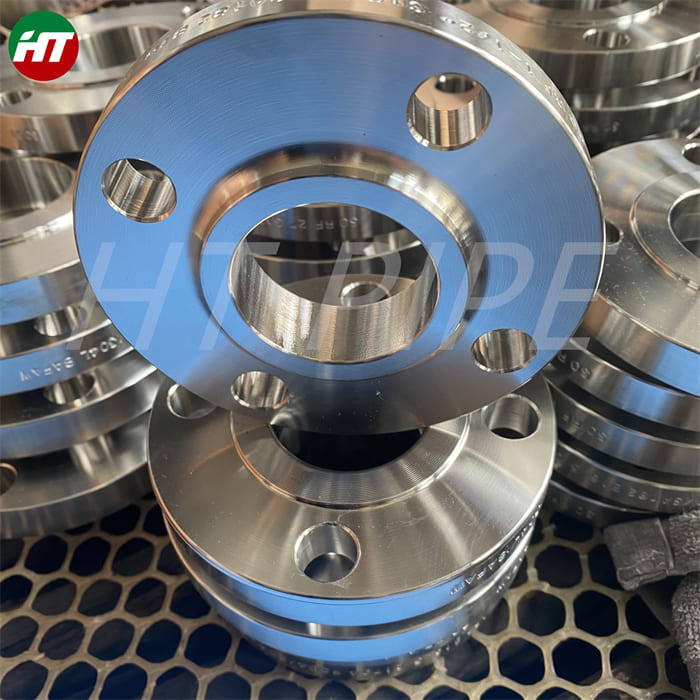

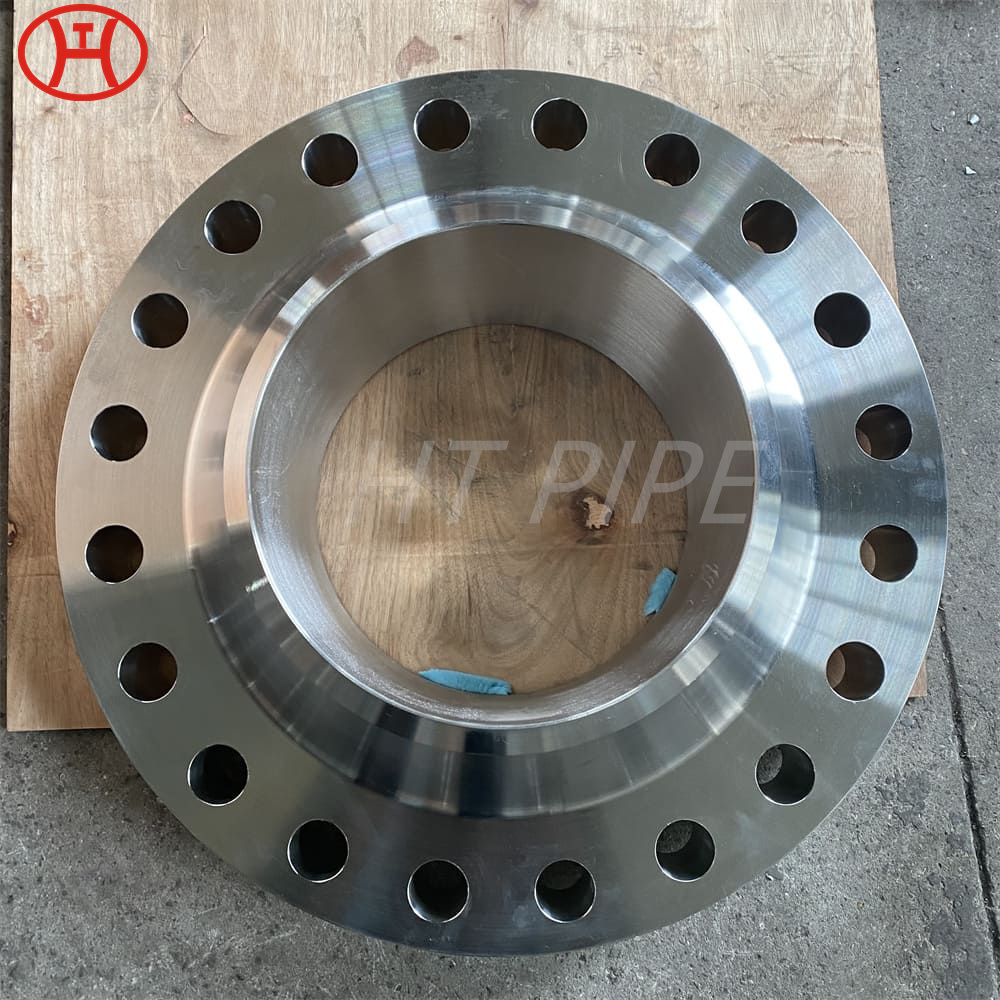

nickel alloy flange epdm rubber flexible adapter Inconel 718 flange WERKSTOFF NR. 2.4668 flange

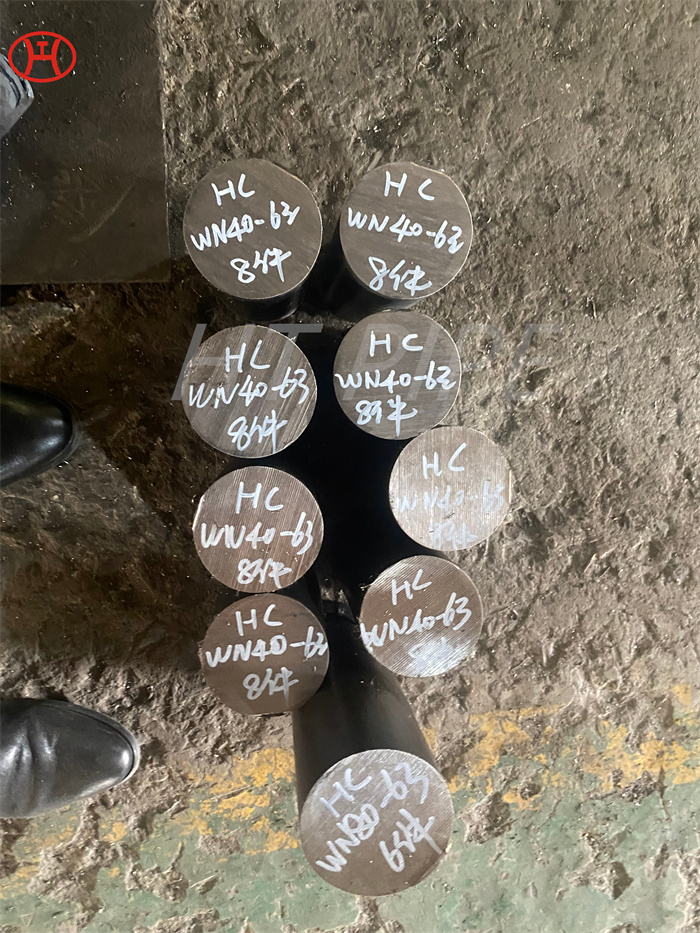

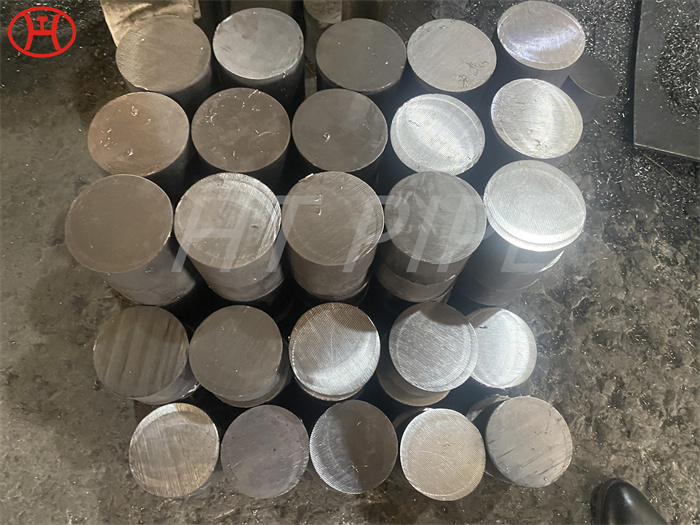

Werkstoff Nr 2.4668 forged parts can be easily machined in the annealed or age hardened condition. While machining the alloy in the age hardened condition yields a better surface finish, machining Inconel 718 alloy in the annealed condition yields longer tool life.

Alloy 718 (AMS 5663) is an aged (precipitation hardened) bar. When supplied, this material has higher tensile strength and hardness than 718 in the annealed condition. Work-aged 718 is generally more difficult than work-annealed material. The benefit is that once machining is complete, the part is complete. Meanwhile, Inconel 718 is a nickel-iron-chromium superalloy with copper and molybdenum, modified with niobium, which tends to age harden alloys. In addition to titanium and aluminum, it also contains cobalt and boron. Material annealing and welding does not spontaneously harden during the entire heating and cooling process. Niobium increases strength without heat treatment. It can be fabricated and welded quickly.