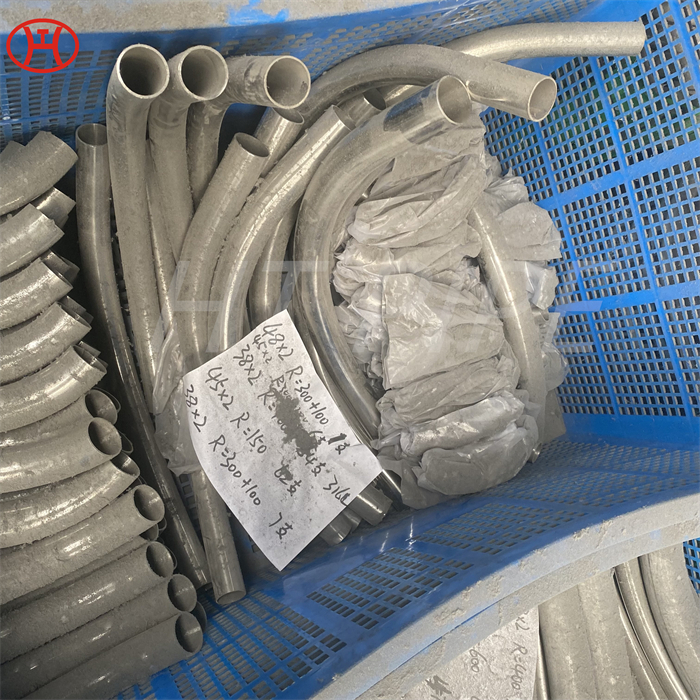

nickel alloy Hastelloy B2 N10665 pipes with y tees and flanges

Nickel- and cobalt-based corrosion-, temperature- and wear-resistant alloys, such as Hastelloy B2, are classified as moderate to difficult when machined, but it should be emphasized that these alloys can be produced at satisfactory speeds using conventional production methods processing. During machining, these alloys harden rapidly, generate high heat during cutting, weld to the cutting tool surface, and provide high resistance to metal removal due to their high shear strength.

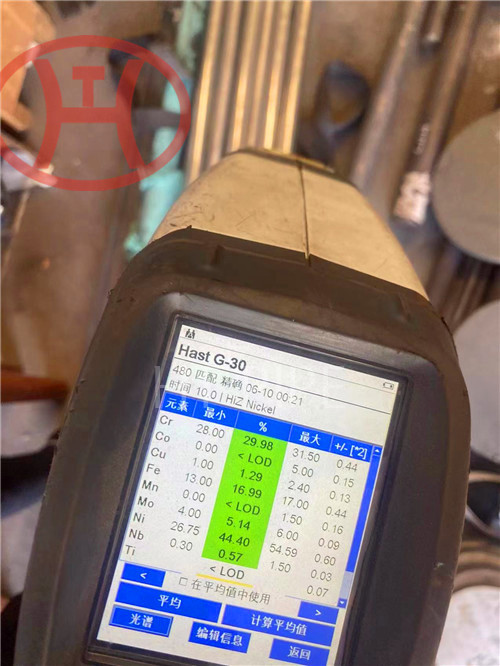

Alloy B2 (UNS N10665 / W.Nr. 2.4617) is a solid solution strengthened nickel molybdenum alloy typically used in extreme reducing conditions. Compared to its predecessor alloy B (UNS N10001), the carbon, silicon and iron content of B2 is significantly reduced, making the alloy less susceptible to reduced corrosion resistance in the weld zone in the as-welded state. Controlling other alloying elements, such as iron and chromium, addresses other concerns about manufacturability.