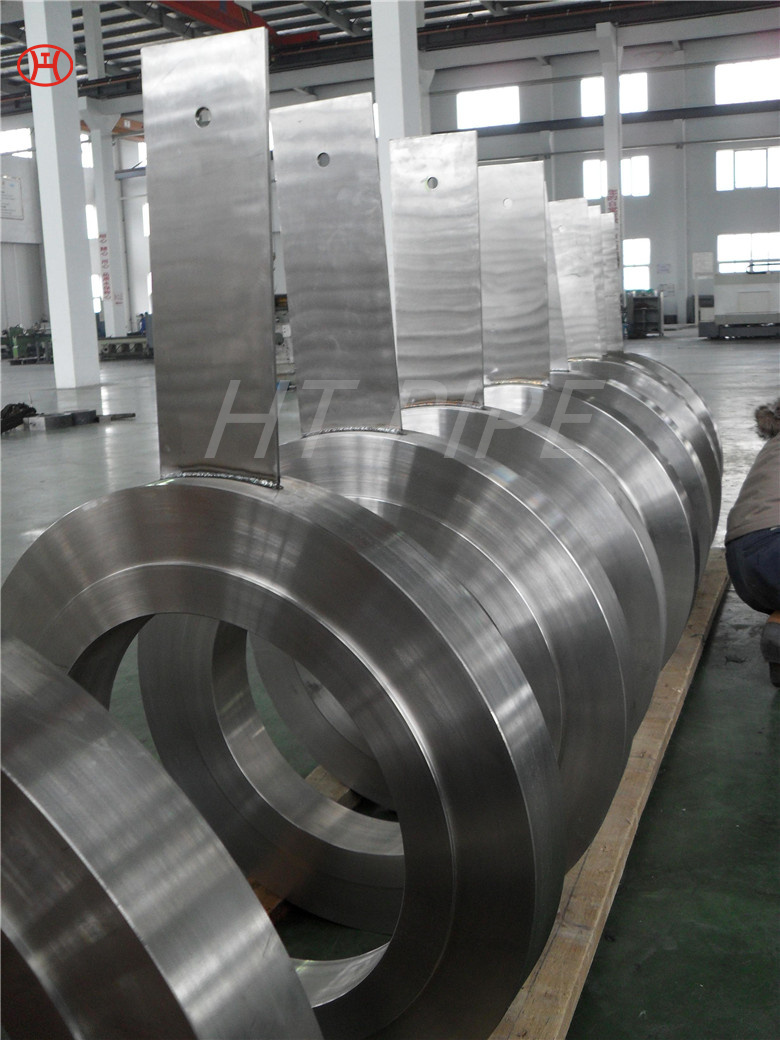

Nickel alloy incoloy 800 800h 800ht pipe and tube N08800 N08810 N08811

Incoloy 800/800H/800HT grade alloys have a variety of special properties and characteristics that make pipes and tubes even more demanding. As a manufacturer and supplier of such products, we ensure that all our products are manufactured according to the needs and requirements of our customers. Therefore, we use high-quality raw materials that are well tested and used according to international quality standards. With it, modern technology and the latest tools can be used to create pipes and tubes of precise size and length.

ASTM B407 UNS N08800 Incoloy 800 Welded Pipe supplier,Incoloy UNS N08825 ERW Tubing Trader, DIN 1.4876 ERW Pipes, UNS N08800 Seamless Tubes Stockists, Incoloy UNS N08811 Welded Pipes Dealer, DIN 2.4858 Tubing, Incoloy Alloy 800 Tubes Supplier in China.

A benefit of using Incoloy 800 pipe is its stability at elevated temperatures. This nickel-iron-chromium alloy can maintain its austenitic microstructure despite the Welded Pipe Incoloy 800 being exposed to elevated temperatures. According to specification ASTM B407, these Incoloy 800 pipes are annealed for 15 minutes at a temperature of 1800°F. After annealing, the Alloy 800 Seamless Pipe is cooled in air.

The ASME SB 407 UNS N08800 has superior resistance to Carburization. ASTM B407 UNS N08800 is a phenomenon that occurs in processing based industries where gas mixtures contain hydrocarbons or Carbon monoxide come in contact with any steel. Carburization generally weakens many regular steel grade and affects their ability to resist both oxidation and sulfidation, due to the depletion of chromium in the matrix and the formation of carbides on the surface of the pipe.

Alloy 800 Seamless Pipes are used in the nuclear power plant and paper pulp industry. These tubes are often used in reforming furnaces of steam methane and also in extruded tubing. They are manufactured both seamless as well as welded forms. These Werkstoff number 1.4876 Pipes are extremely resistant to corrosion, even if ASME SB 515 Incoloy Alloy 800 Welded Tube is in an acidic environment. Incoloy 800 Round Pipe is used in a wide range by many industries throughout the world for a number of applications, especially for those which deal with temperatures about 600 Degree C.

Chemical Composition Of Incoloy 800 Seamless Pipes :

| Incoloy | 800 | 800H | 800HT |

| Ni | 30-35 | 30-35 | 30-35 |

| Fe | 39.5 min | 39.5 min | 39.5 min |

| Cr | 19-23 | 19-23 | 19-23 |

| Cu | 0.75 max | 0.75 max | 0.75 max |

| Ti | 0.15-0.60 | 0.15-0.60 | 0.25-0.60 |

| Al | 0.15-0.60 | 0.15-0.60 | 0.85-1.20 |

| C | 0.1 max | 0.05-0.1 | 0.06-0.1 |

| Mn | 1.5 max | 1.5 max | 1.5 max |

| S | 0.015 max | 0.015 max | 0.015 max |

| Si | 1.0 max | 1.0 max | 1.0 max |

Incoloy 800 Welded Pipes Mechanical & Physical Properties :

| Density | 7.94 g/cm3 |

| Melting Point | 1385 °C (2525 °F) |

| Tensile Strength | Psi – 75,000 , MPa – 520 |

| Yield Strength (0.2%Offset) | Psi – 30,000 , MPa –205 |

| Elongation | 30 % |