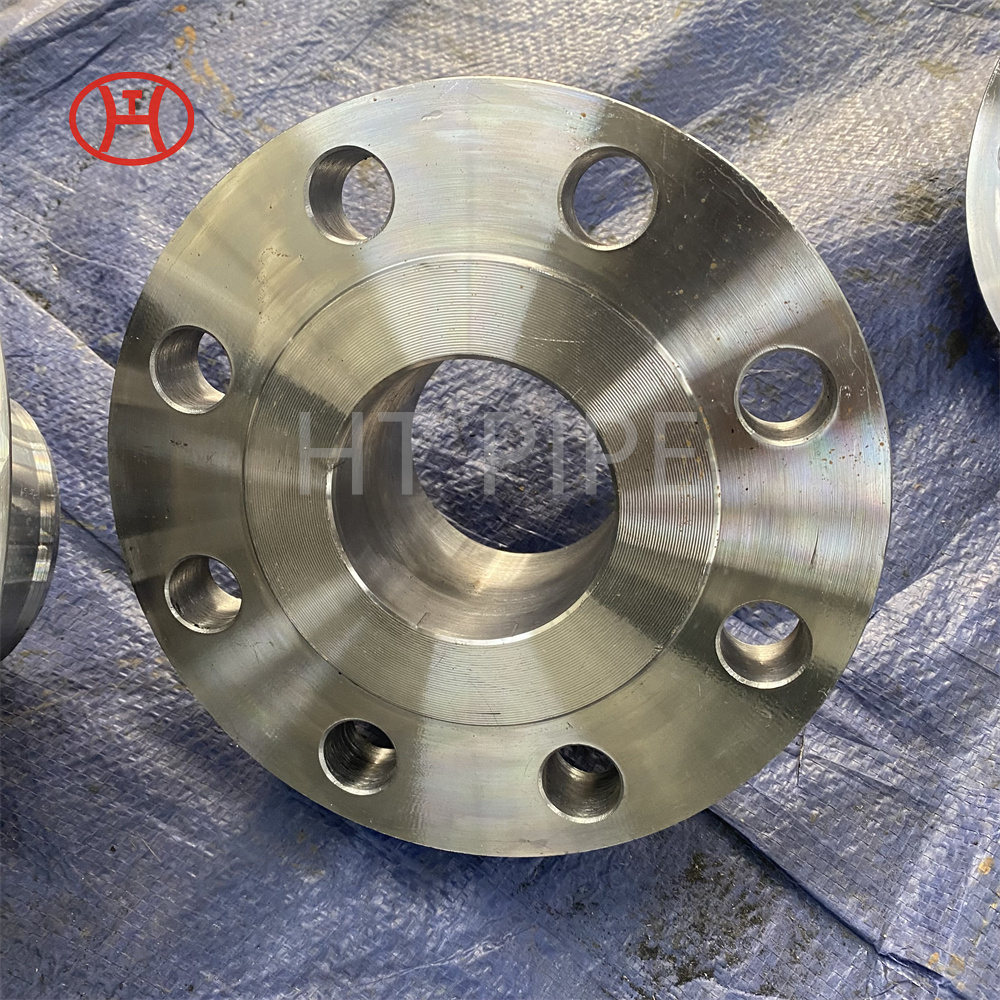

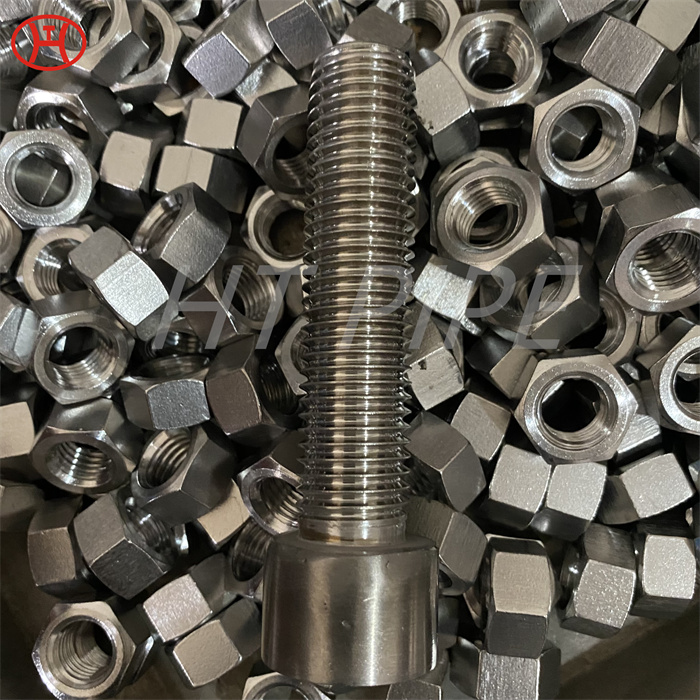

nickel alloy Inconel 718 2.4668 elbows with reducers

Inconel 718 is a nickel-based superalloy ideal for applications requiring high strength in the temperature range from cryogenic to 1400¡ãF. Inconel 718 also has excellent tensile and impact strength.

Developed in the early 1960s, IN718 is still considered the material of choice for most aircraft engine components operating at temperatures below 1200¡ãF (650¡ãC). Inconel 718 is a precipitation hardenable nickel-chromium alloy that also contains significant amounts of iron, niobium and molybdenum and small amounts of aluminum and titanium. It combines corrosion resistance and high strength with excellent weldability, including resistance to post weld cracking. This alloy has excellent creep rupture strength at temperatures up to 1300¡ãF (700¡ãC).

Supplier of Inconel Alloy 718 (UNS N07718), a nickel-based superalloy commonly used in cryogenic storage tanks, turbines, downhole shafting and wellhead components. High resistance to very high and very low temperatures allows Inconel 718 to be welded and annealed into products that can withstand extreme conditions. Other uses include jet rockets, nuclear fuel and pump body parts.