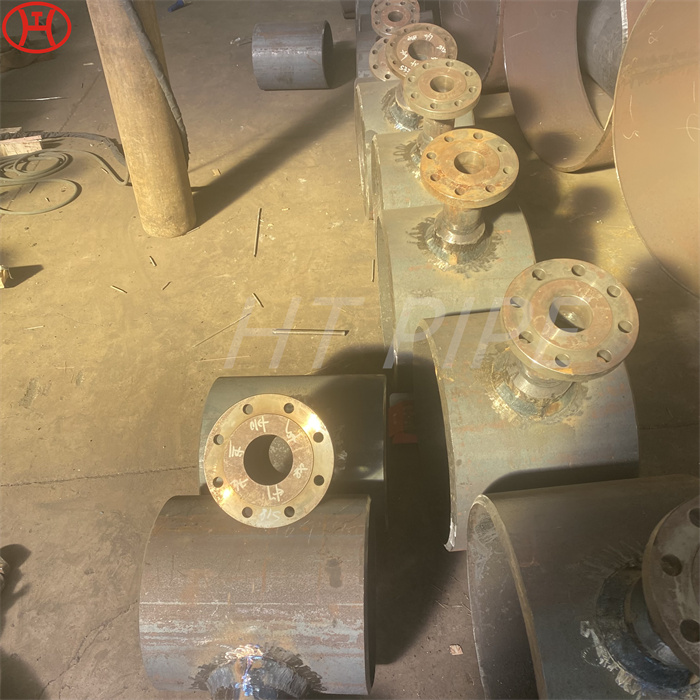

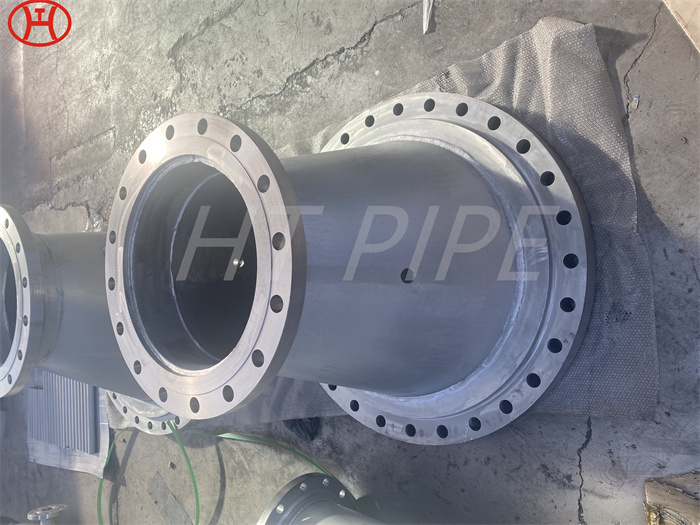

nickel alloy N10276 hastelloy c276 pipe tube erw steel pipe

NAS NW276 is a Ni Cr Mo alloy with excellent corrosion resistance in both oxidizing and reducing atmospheres. In this alloy, carbide precipitation in the heat affected zone (HAZ) is suppressed and corrosion resistance is improved by reducing the contents of C and Si.

Workability

Because the high temperature strength of NAS NW276 is extremely higher than that of Type 304, care is required when hot working. The cold workability of NAS NW276 is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. However, the fact that this is a high strength material must be considered in cold working.

Weldability

In welding, it is possible to apply ordinary welding methods in the same manner as with stainless steels. Matching composition welding consumables should be used. Post weld heat treatment is not required.

Heat Treatment

Solution annealing of NAS NW276 is normally performed at the temperature range from 1150 to 1170℃ followed by being quenched in water or rapidly cooled by other means.

Pickling

A mixture of nitric acid and fluoric acid is used in pickling. However, because descaling is somewhat difficult in comparison with Type 304, alkali immersion before acid pickling, and if possible, shot blasting are extremely effective.

Applications

Heat exchangers, centrifugal separators, driers, reaction vessels, salt manufacturing plants, flue gas desulfurization plants