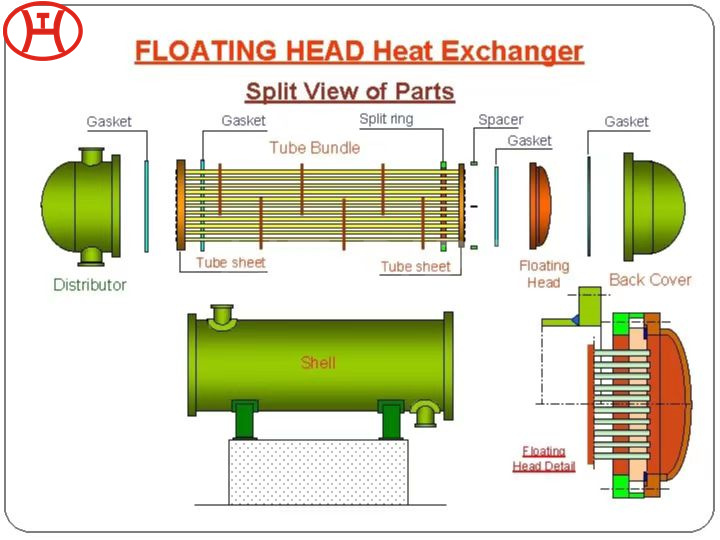

nickel alloy pipe Incoloy N08800 in floating head heat exchanger

Talking about the general properties exhibited by Incoloy 800 grades, Incoloy 800/800H/800HT pipe exhibits excellent corrosion resistance, pitting resistance in chloride environments, resistance to various acidic environments, good general corrosion resistance, flow resistance Grain alloy crack corrosion, crevice corrosion resistance and easier weldability and hardness.

ASTM B407/B358 Incoloy 800H pipe has proven to be a valuable and versatile material that can solve a variety of design and application problems. ASTM B407/B358 Incoloy 800H tubing resists low temperature aggressive corrosive environments as well as harsh high temperature environments.

Incoloy alloys are also a family of superalloys produced by Special Metals Corporation. They are nickel-iron-chromium alloys used in applications requiring high corrosion resistance and high temperature strength. Incoloy alloys are very similar to Inconel alloys, but their different compositions allow for different applications.

Alloy 800 is a widely used material of construction for equipment that must resist corrosion, have high strength or be resistant to oxidation, carburization and other harmful effects of high temperature exposure. Chromium in the alloy imparts resistance to oxidation and corrosion. The high nickel content maintains the austenitic structure, making the alloy ductile. Nickel also helps resist scaling, general corrosion and stress corrosion cracking. Iron content provides resistance to internal oxidation.